In situ preparation method of layered double hydroxy metal oxide film on the surface of al-cu-li alloy

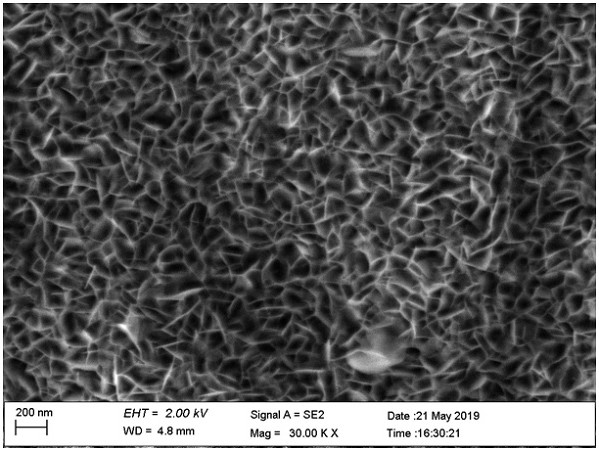

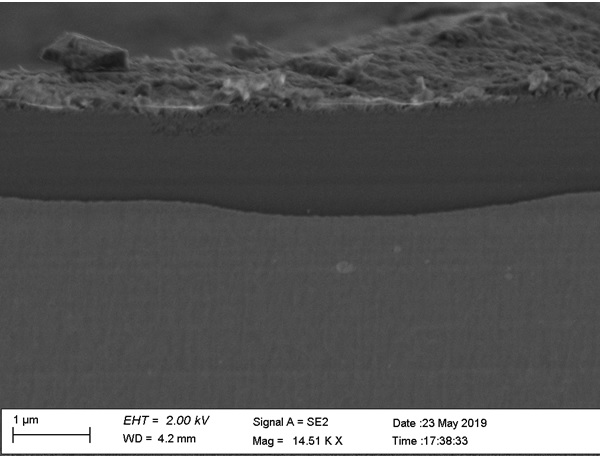

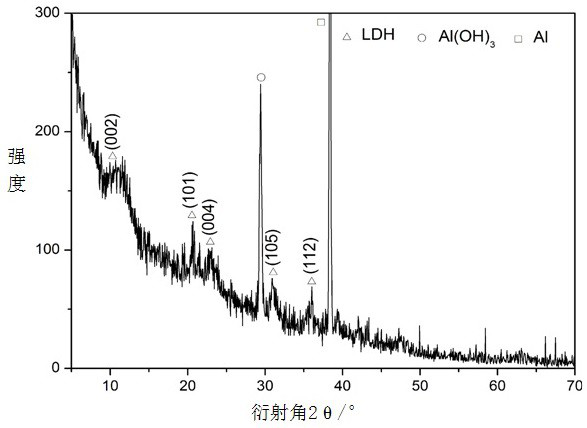

A technology of double hydroxyl metal and oxide thin film, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of unsatisfactory industrial production, no LDH film, long preparation time, etc., and achieve improvement Surface chemical activity, excellent corrosion resistance, uniform and dense film effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, an in-situ preparation method of a layered double hydroxy metal oxide film on the surface of an Al-Cu-Li alloy, which includes the following steps.

[0032] a. Pretreatment, take the polished AA2099 aluminum-lithium alloy sample for alkali etching process, put the polished side up into a 10wt.% NaOH aqueous solution, keep it at a constant temperature for 300s at a temperature of 60°C, take it out and use it Rinse with ion water, then carry out pickling process immediately, put the polished side of AA2099 aluminum-lithium alloy sample into 30vol.% HNO horizontally 3 The chemical deashing was carried out in the aqueous solution for 30 s, then it was taken out and rinsed with deionized water, and finally dried with cold air to obtain the pretreated AA2099 Al-Li alloy sample.

[0033] b. Prepare a lithium carbonate solution with a concentration of 0.1M, and adjust the pH of the lithium carbonate solution to 12.0 with lithium hydroxide.

[0034] c. Put the pre...

Embodiment 2

[0038] Embodiment 2, an in-situ preparation method of a layered double hydroxy metal oxide film on the surface of an Al-Cu-Li alloy, which includes the following steps.

[0039] a. Pretreatment, take the polished AA2099 aluminum-lithium alloy sample for alkali etching process, put the polished side up into a 10wt.% NaOH aqueous solution, keep it at a constant temperature for 300s at a temperature of 60°C, take it out and use it Rinse with ion water, then carry out pickling process immediately, put the polished side of AA2099 aluminum-lithium alloy sample into 30vol.% HNO horizontally 3 The chemical deashing was carried out in the aqueous solution for 30 s, then it was taken out and rinsed with deionized water, and finally dried with cold air to obtain the pretreated AA2099 Al-Li alloy sample.

[0040] b. Prepare a lithium carbonate solution with a concentration of 0.1M, and adjust the pH of the lithium carbonate solution to 12.5 with lithium hydroxide.

[0041] c. Put the pre...

Embodiment 3

[0043] Embodiment 3, an in-situ preparation method of a layered double hydroxy metal oxide film on the surface of an Al-Cu-Li alloy, which includes the following steps.

[0044] a. Pretreatment, take the polished AA2099 aluminum-lithium alloy sample for alkali etching process, put the polished side up into a 10wt.% NaOH aqueous solution, keep it at a constant temperature for 300s at a temperature of 60°C, take it out and use it Rinse with ion water, then carry out pickling process immediately, put the polished side of AA2099 aluminum-lithium alloy sample into 30vol.% HNO horizontally 3 The chemical deashing was carried out in the aqueous solution for 30 s, then it was taken out and rinsed with deionized water, and finally dried with cold air to obtain the pretreated AA2099 Al-Li alloy sample.

[0045] b. Prepare a lithium carbonate solution with a concentration of 0.05M, and adjust the pH of the lithium carbonate solution to 13.0 with lithium hydroxide.

[0046] c. Put the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com