A method and circuit for calibrating the temperature signal of the secondary reheat steam temperature in a thermal power plant

A technology of secondary reheating and temperature signal, used in thermometer testing/calibration, limiting amplitude with diodes, thermometers, etc. It can solve the problems of not considering signal errors and inaccurate signals, so as to improve accuracy and ensure signals The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

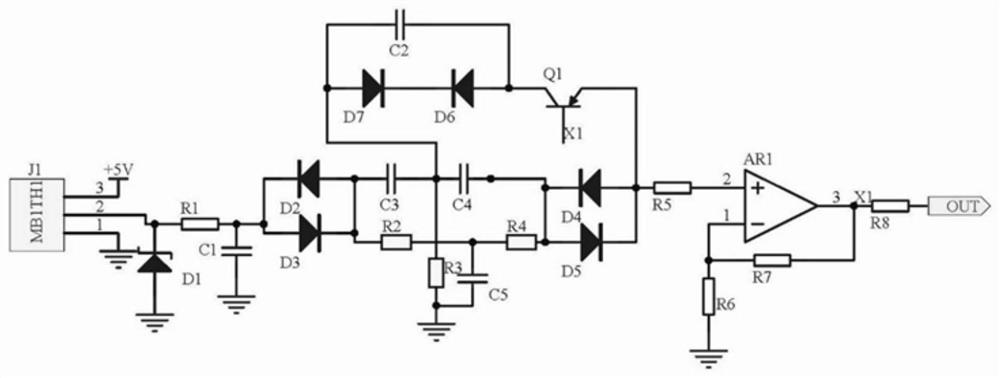

[0048] see figure 1 According to an embodiment of the present invention, a circuit for calibrating the temperature signal of the secondary reheated steam in a thermal power plant includes: a temperature acquisition circuit, a feedback noise reduction circuit, and an operational amplifier output circuit.

[0049] The temperature acquisition circuit uses the temperature collector J1 of the model MB1TH1 to collect the temperature signal of the secondary reheating steam temperature of the thermal power plant.

[0050] The feedback noise reduction circuit uses the diode D2 to the diode D5 and the capacitor C3 to the capacitor C5 to form a limiting frequency modulation circuit to symmetrically limit the signal and at the same time play a role in frequency selection; among them, the transistor Q1 detects the output signal of the limiting frequency modulation circuit and the operational amplifier The potential difference of the AR1 output signal, and the noise reduction circuit compos...

Embodiment 2

[0053] On the basis of Embodiment 1, the operational amplifier output circuit uses the operational amplifier AR1 to amplify the signal in phase and then outputs it, which is the temperature calibration signal of the secondary reheating steam temperature control terminal of the thermal power plant; specifically, the in-phase input of the operational amplifier AR1 One end of the resistor R5 is connected, the other end of the resistor R5 is connected to the positive pole of the diode D4, the inverting input of the operational amplifier AR1 is connected to the resistor R6 and one end of the resistor R7, the other end of the resistor R6 is grounded, and the other end of the resistor R7 is connected to the op amp. The output terminal of the amplifier AR1 and the base of the triode Q1, one end of the resistor R8, and the other end of the resistor R8 are connected to the signal output port; the temperature acquisition circuit is selected as the temperature collector J1 of the MB1TH1 mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com