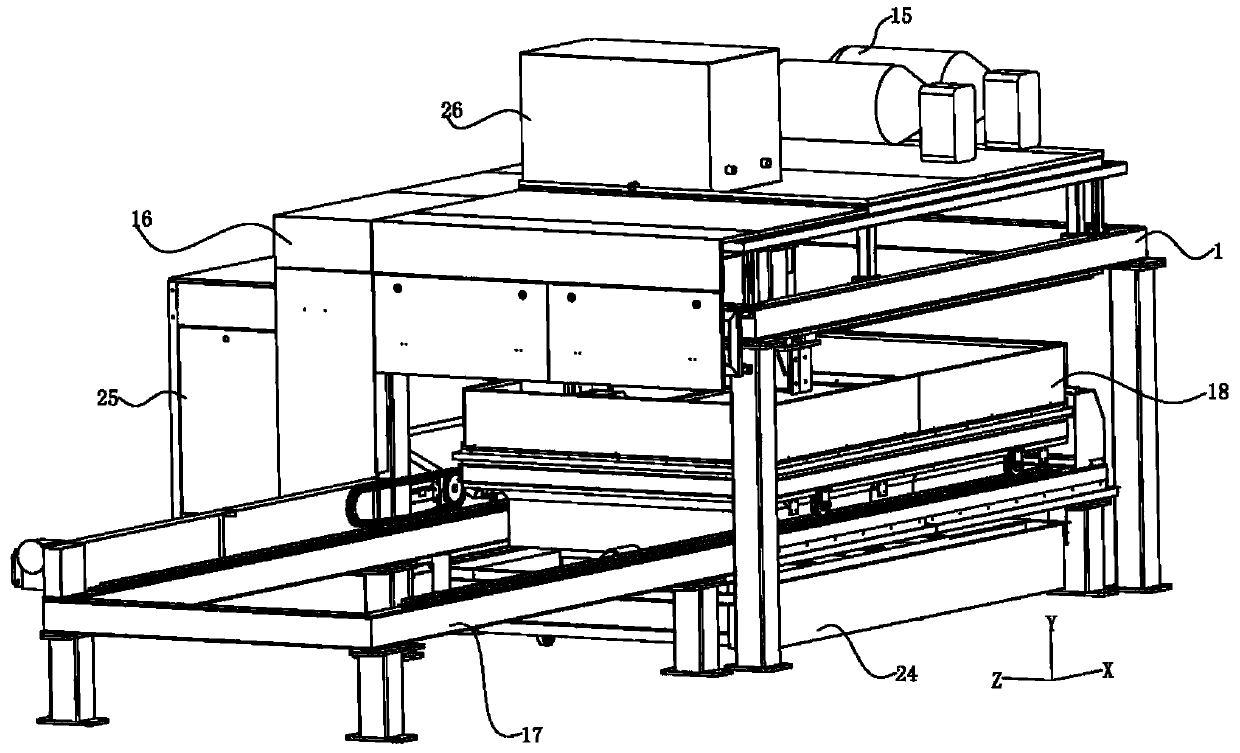

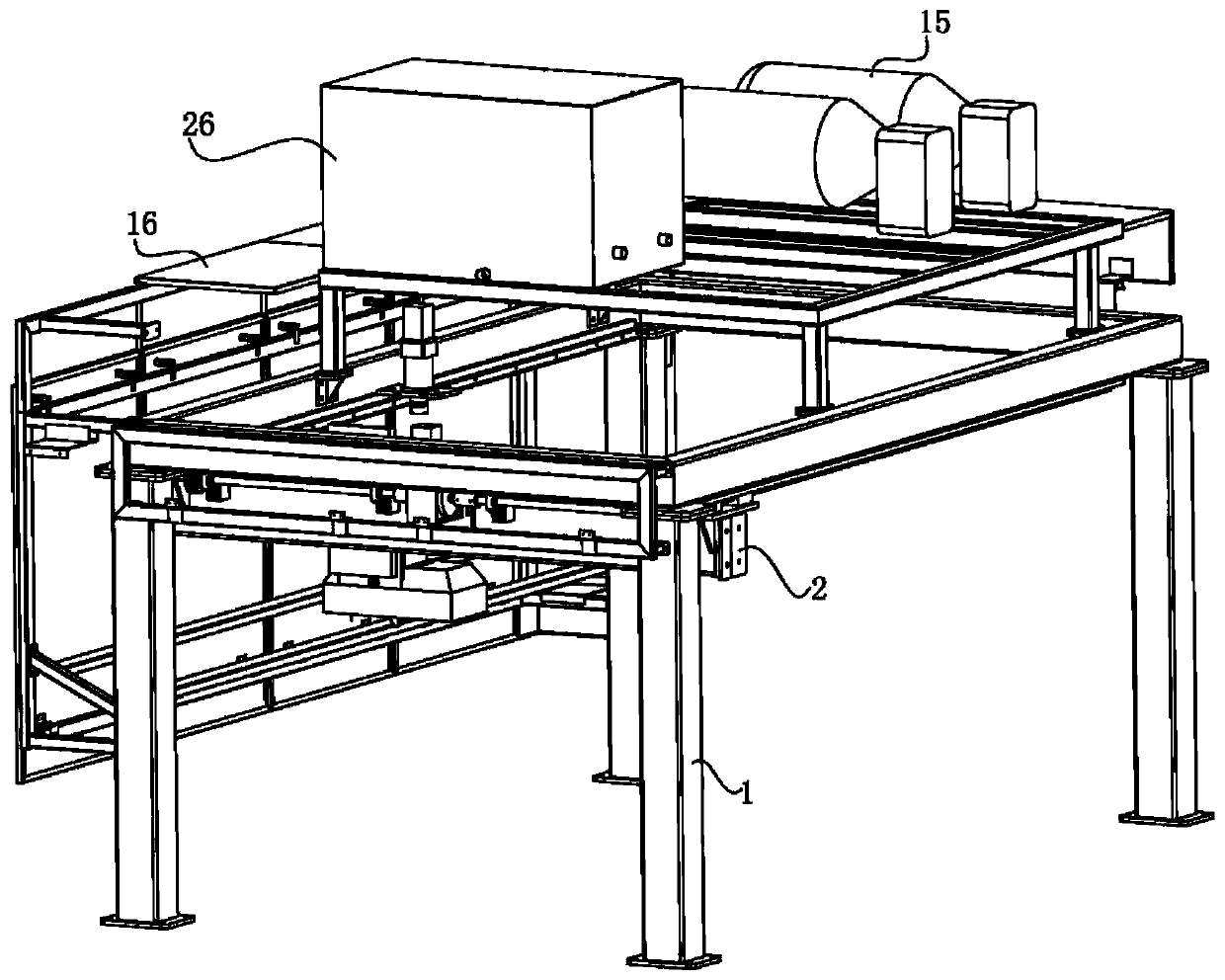

Disassembling device for photovoltaic module

A photovoltaic module and injection device technology, applied in the field of photovoltaic module dismantling devices, can solve problems such as difficulties, low efficiency, and treatment processes that need to be improved, and achieve the effects of increased crushing rate, improved dismantling efficiency, and improved dismantling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

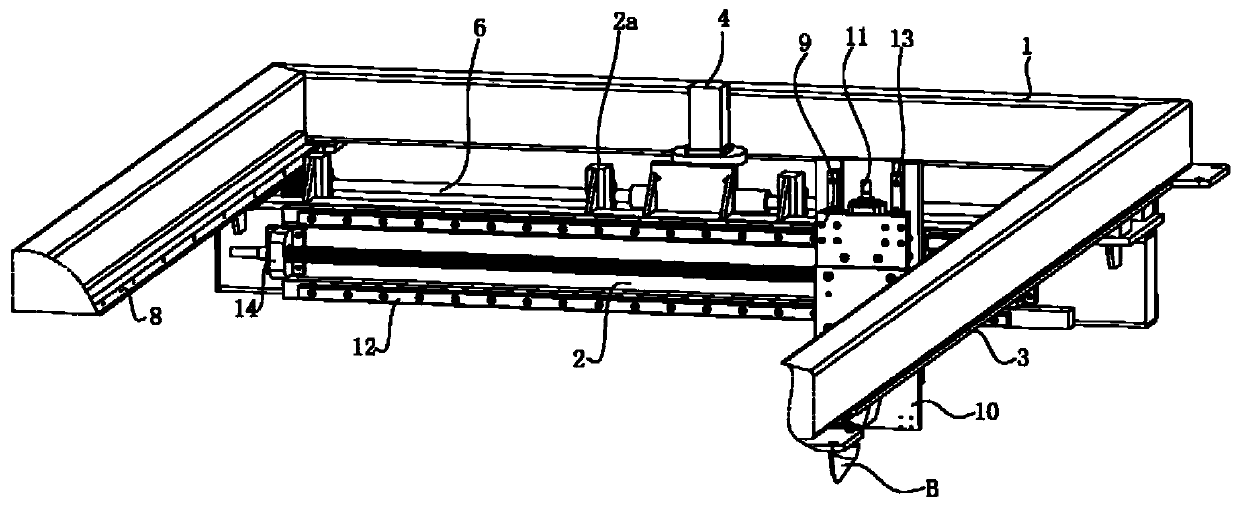

[0069] Step S1: the jetting device for jetting the fluid is opposite to the back of the photovoltaic module A, such as Figure 9 As shown in the figure, the flow direction of the liquid-containing fluid sprayed by the spray device forms an inclination angle with the back surface of the photovoltaic module A in a non-vertical state; wherein, the fluid is water or a mixture of water and abrasive, and the abrasive is preferably sand, and the fraction of abrasive and water is used. The ratio is: 1-2:98-99, that is, in 100 parts of fluid, the abrasive contained is 1-2 parts, and the water contained is 98-99. By adding abrasives, the cutting of the photovoltaic modules by the abrasives can improve the dismantling efficiency.

[0070] Step S2: controlling the pressure of the jetting fluid from the jetting device, that is, controlling the pressure of the fluid output from the pump 15, so that the fluid containing the liquid forms an incision O on the back of the photovoltaic module, s...

Embodiment 2

[0083] The difference between the dismantling method of this embodiment and the above-mentioned Embodiment 1 is:

[0084] The incision O is a rectangular incision. The pressure of the fluid acting on the back of the photovoltaic module A was 52 MPa. The distance L is 0.7 meters. The first inclination angle α is 60°, and the second inclination angle β is 120°. The first drive mechanism drives the moving beam 2 to drive the nozzle B to move at a speed of 3.2 m / min along the lateral direction X, and the second drive mechanism 14 drives the support 9 to drive the nozzle B to move along the longitudinal direction Z at a speed of 0.9 m / minute.

[0085] According to the dismantling method of Example 2, the dismantling time of one photovoltaic module A is 13.4 minutes.

Embodiment 3

[0087] The difference between the dismantling method of this embodiment and the above-mentioned Embodiment 1 is:

[0088] The incision O is a rectangular incision. The pressure of the fluid acting on the back of the photovoltaic module A is 50MPa. The distance L is 0.5 meters. The first inclination angle α is 50°, and the second inclination angle β is 130°. The first drive mechanism drives the moving beam 2 to drive the nozzle B to move at a speed of 3.0 m / min along the transverse direction X, and the second drive mechanism 14 drives the support 9 to drive the nozzle B to move along the longitudinal direction Z at a speed of 0.8 m / minute.

[0089] According to the dismantling method of Example 3, the dismantling time of one photovoltaic module A is 14 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com