Activation method of proton exchange membrane fuel cell

A proton exchange membrane, fuel cell technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve problems such as shortening the activation time of ordered cells, reducing hydrogen consumption, poor membrane electrode performance, etc., to achieve improved activation. Efficiency, improved performance, efficient and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

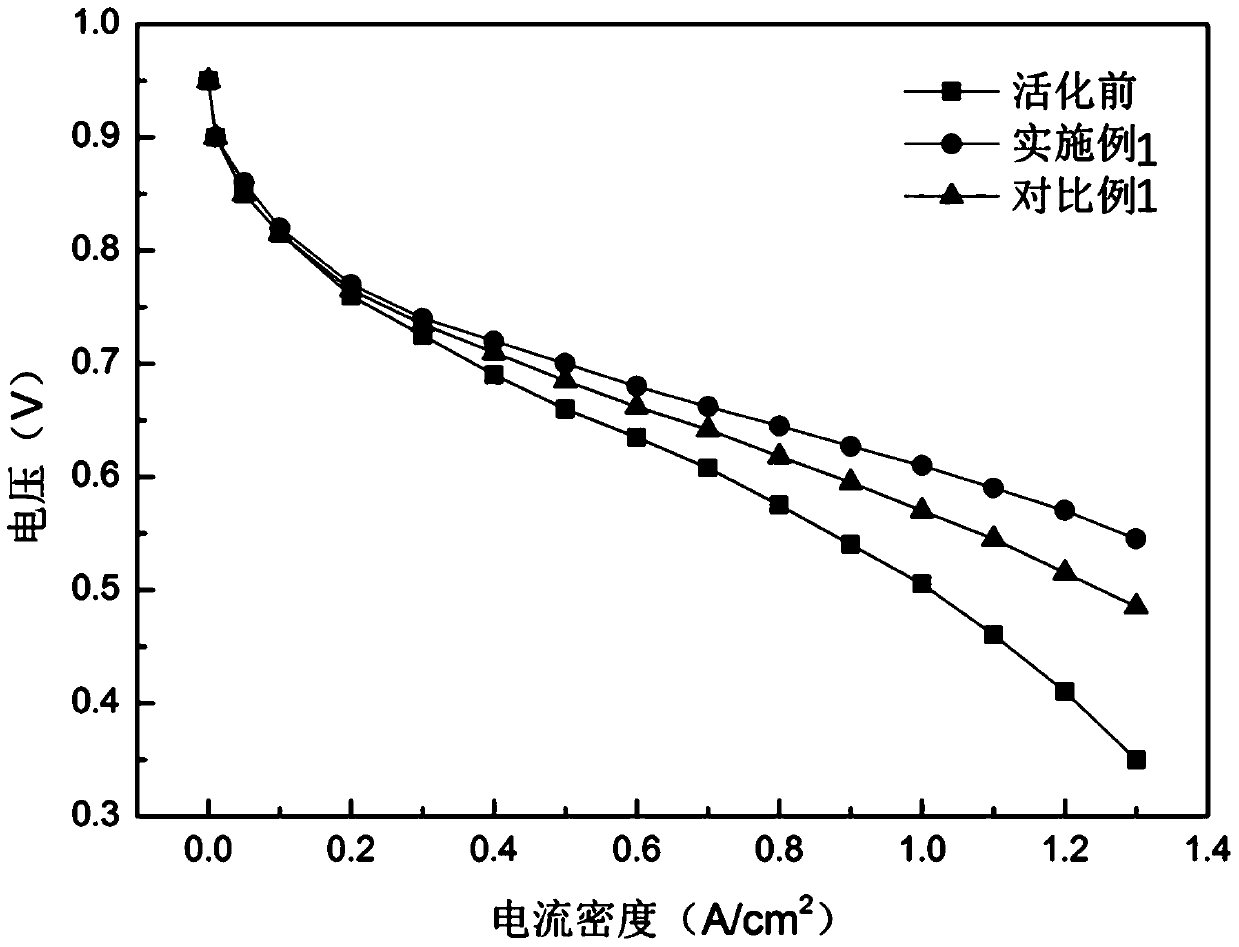

Embodiment 1

[0074] This embodiment provides a method for activating a proton membrane exchange membrane fuel cell. The test object of this embodiment is that the effective active area is 50 cm 2 The monolithic battery comprises the following steps:

[0075] (1) The proton exchange membrane fuel cell to be activated is connected on the test bench, and the flow rate is 2L / min dry nitrogen for 5min to the anode side and the cathode side, and then the flow rate is 2L / min and the humidity is 60%RH. Humidify nitrogen, and adjust the operating temperature of the proton exchange membrane fuel cell to 70°C for 15 minutes;

[0076] (2) The flow rate of 0.03L / min and the humidity of 60%RH are passed into the anode side for 15s, and the flow rate of the cathode side is 0.2L / min and the humidity is 60%RH of humidified air for 15s, and then the proton exchange membrane fuel is set. The battery operates in constant voltage mode, so that the voltage of each single cell in the proton exchange membrane fu...

Embodiment 2

[0084] This embodiment provides a method for activating a proton membrane exchange membrane fuel cell. The test object of this embodiment is a single sheet with an effective active area of 50 cm 2 The stack consists of 5 single cells, including the following steps:

[0085] (1) The proton exchange membrane fuel cell to be activated is connected on the test bench, and the flow rate is 10L / min dry nitrogen for 15min to the anode side and the cathode side, and then the flow rate is 10L / min and the humidity is 100%RH. Humidify nitrogen, and adjust the operating temperature of the proton exchange membrane fuel cell to 60°C for 40 minutes;

[0086] (2) The flow rate of 0.15 L / min and humidity of 100% RH are passed into the anode side for 40 seconds, and the flow rate of 1 L / min into the cathode side is humidified air of 100% RH for 40 seconds, and then the proton exchange membrane fuel cell is set. Operate in constant voltage mode so that the voltage of each single cell in the pr...

Embodiment 3

[0094]This embodiment provides a method for activating a proton membrane exchange membrane fuel cell. The test object of this embodiment is a single sheet with an effective active area of 50 cm 2 The stack consists of 10 single cells, including the following steps:

[0095] (1) The proton exchange membrane fuel cell to be activated is connected on the test bench, and the flow rate is 30L / min dry nitrogen for 10min to the anode side and the cathode side, and then the flow rate is 30L / min and the humidity is 80%RH. Humidify nitrogen, and adjust the operating temperature of the proton exchange membrane fuel cell to 80°C for 10 minutes;

[0096] (2) The flow rate of 0.3L / min into the anode side is humidified hydrogen with a humidity of 80%RH for 10s, and the flow rate of 2L / min into the cathode side is humidified air with a humidity of 100%RH for 10s, and then the proton exchange membrane fuel cell is set Operate in constant current mode so that the voltage of each single cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com