Preparation technology of high-strength aluminum alloy precision casting board

A technology of precision casting and preparation process, applied in the field of material processing, can solve the problems of insufficient, processing deformation casting plate strength, incomplete stress release, etc., and achieve the effect of eliminating internal stress, improving plate strength, and being difficult to process deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

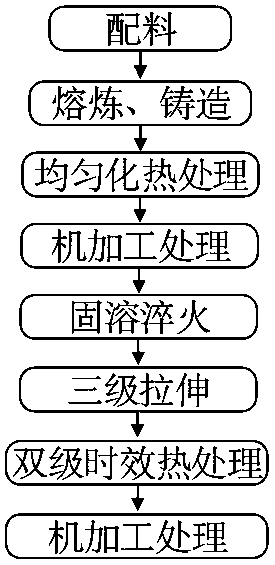

[0038] Please refer to figure 1 , This preferred embodiment provides a process for preparing a high-strength aluminum alloy precision casting plate, which includes the following steps:

[0039] S1. Ingredients: ingredients according to the following weight percentages: Zn=5.5%, Mg=2.47%, Cu=1.8%, Si=0.12%, Fe=0.20%, Mn=0.09%, Cr=0.12%, Ti=0.02% , Zr=0.03%, the rest is Al and unavoidable impurities, this composition belongs to 7075 grade aluminum alloy. The components of this preferred embodiment are shown as A1 in Table 1.

[0040] S2. Melting and casting: Melting and casting are carried out according to the above ingredients to cast an ingot with a size of 360×1460×6700mm. During the smelting and casting process, the aluminum alloy melt is subjected to multi-stage degassing treatment to significantly reduce the gas content in the aluminum alloy melt and reduce the casting defects such as pores and porosity in the aluminum alloy ingot. Use a filter plate to remove oxides, non-met...

Embodiment 2

[0056] Please refer to figure 1 , This preferred embodiment provides a process for preparing a high-strength aluminum alloy precision casting plate, which includes the following steps:

[0057] S1. Ingredients: ingredients according to the following weight percentages: Zn=6.6%, Mg=2.40%, Cu=2.5%, Si=0.01%, Fe=0.02%, Mn=0.01%, Cr=0.01%, Ti=0.02% , Zr = 0.07%, the rest is Al and unavoidable impurities, this composition belongs to 7050 grade aluminum alloy. The components of this preferred embodiment are shown in Table 1 as B1.

[0058] S2. Melting and casting: Melting and casting are carried out according to the above ingredients to cast an ingot with a size of 520×1580×5800mm. During the smelting and casting process, the aluminum alloy melt is subjected to multi-stage degassing treatment to significantly reduce the gas content in the aluminum alloy melt and reduce the casting defects such as pores and porosity in the aluminum alloy ingot. Use a filter plate to remove oxides, non-m...

Embodiment 3

[0074] Please refer to figure 1 , This preferred embodiment provides a process for preparing a high-strength aluminum alloy precision casting plate, which includes the following steps:

[0075] S1. Ingredients: ingredients according to the following weight percentages: Zn=6.25%, Mg=2.34%, Cu=2.41%, Si=0.02%, Fe=0.04%, Mn=0.01%, Cr=0.01%, Ti=0.02% , Zr = 0.11%, the rest is Al and unavoidable impurities, this composition belongs to 7150 grade aluminum alloy. The components of this preferred embodiment are shown in Table 1 as C1.

[0076] S2. Melting and casting: Melting and casting are carried out according to the above ingredients to cast an ingot with a size of 420×1720×4500mm. During the smelting and casting process, the aluminum alloy melt is subjected to multi-stage degassing treatment to significantly reduce the gas content in the aluminum alloy melt and reduce the casting defects such as pores and porosity in the aluminum alloy ingot. Use a filter plate to remove oxides, non...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com