High-zinc, low-copper aluminum alloy with excellent corrosion resistance and preparation method thereof

A copper-aluminum alloy, corrosion-resistant technology, applied in the field of alloy materials, can solve problems such as lack of mature theory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

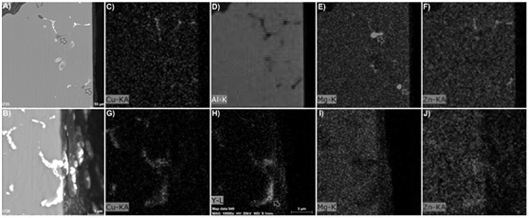

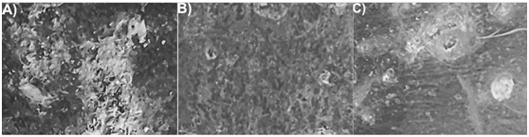

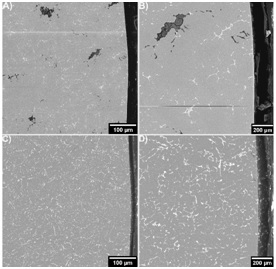

Image

Examples

Embodiment

[0019] This embodiment is only used to illustrate the effects of the present invention. The smelting method in this example is a special small-batch smelting method adopted in the laboratory. The smelting is carried out under the protection of argon gas, and the degassing and other processes in actual production are omitted. In actual production, it can be smelted according to the degassing and refining method of 7 series aluminum alloys, which can further improve the quality and performance of ingots, such as strength, plasticity, and porosity.

[0020] Carry out batching according to Table 1 with weight percentage. The metal blocks of Al, Zn, Mg, Cr and Y have a purity greater than 99.9% and a total weight of 20g. In order to supplement the volatilization loss of Zn during smelting, the excess weight of Zn is 3%.

[0021] serial number Zn(g) Mg(g) Cu(g) Al-Cr(g,10%Cr) Y(g) Al(g) ① 2.266 0.4330 0.34 0.14 0.0000 16.90 ② 2.266 0.4326 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com