Preparation method, product and application of self-supporting silver sulfide catalytic carbon dioxide reduction electrode material

A technology of silver sulfide catalyzing carbon dioxide and electrode materials, which is applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., and can solve problems affecting Faradaic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of ionic liquid system: Ethaline was selected as eutectic ionic liquid, and then 0.0005 mol of sulfur salt precursor (thiourea) was added to 50 mL of Ethaline, and the ionic liquid-sulfur salt composite was obtained after thorough stirring and mixing. electrolytic system;

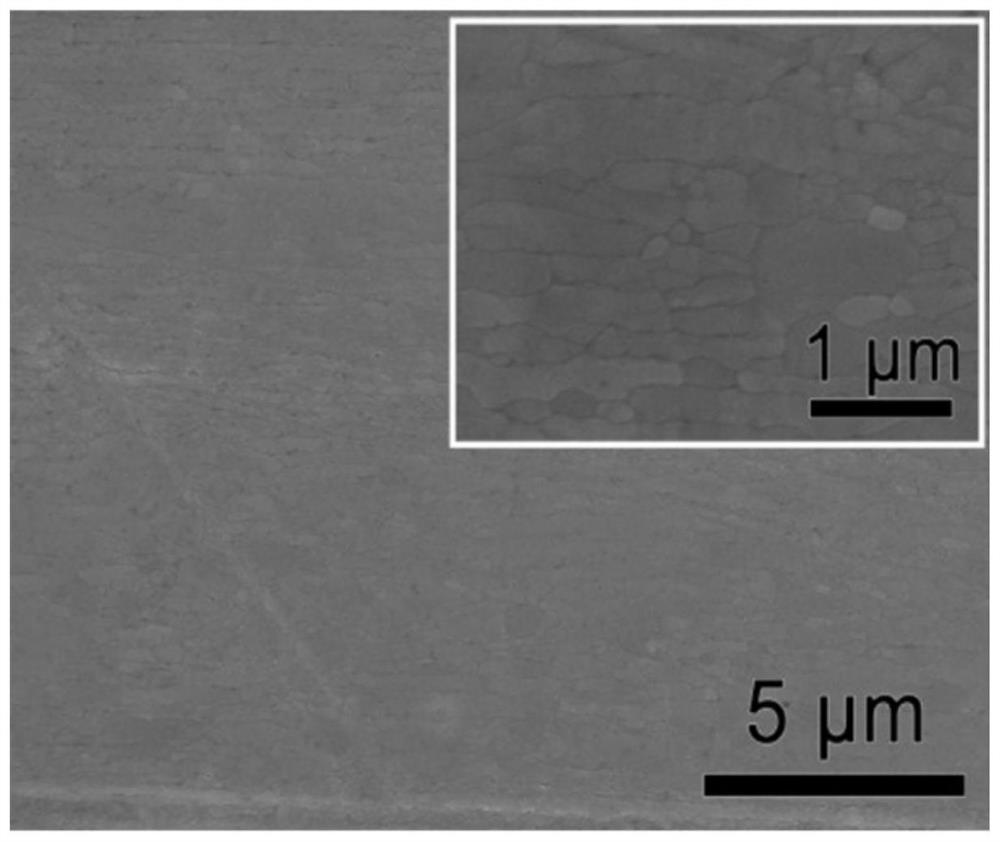

[0030] (2) Substrate pretreatment: take silver flakes (1.5cm×1.5cm×0.1cm) as the substrate, silver soaked in dilute sulfuric acid (concentration is 2M dilute sulfuric acid for 15min), absolute ethanol (concentration is 95% absolute ethanol) soaking for 10 min), soaking in dilute sulfuric acid (1% dilute sulfuric acid soaking for 10 min), rinsing with deionized water to treat the surface of the substrate;

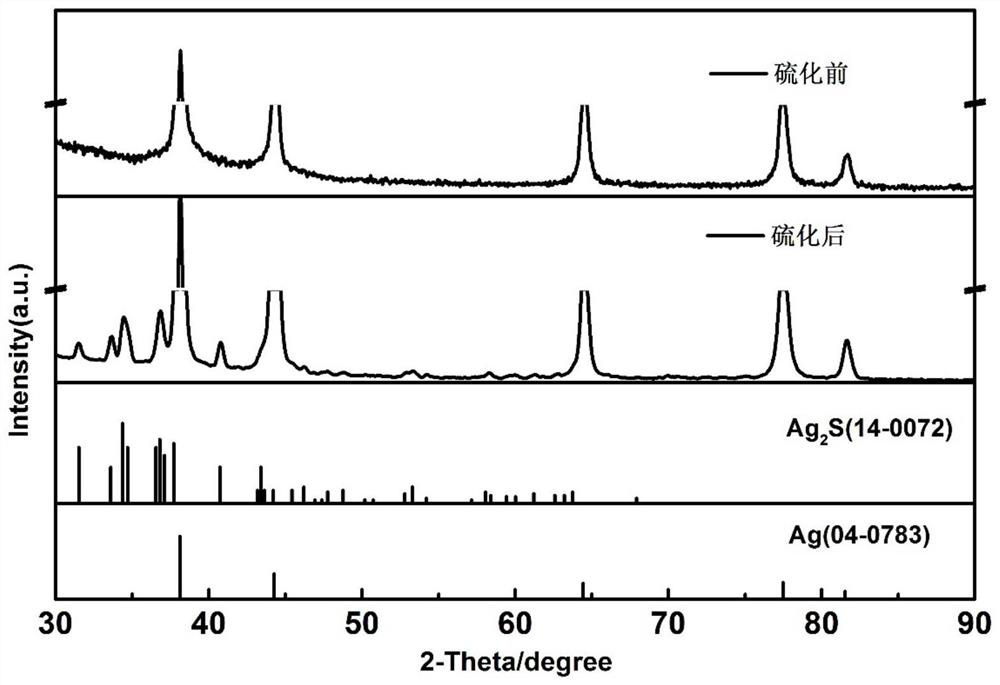

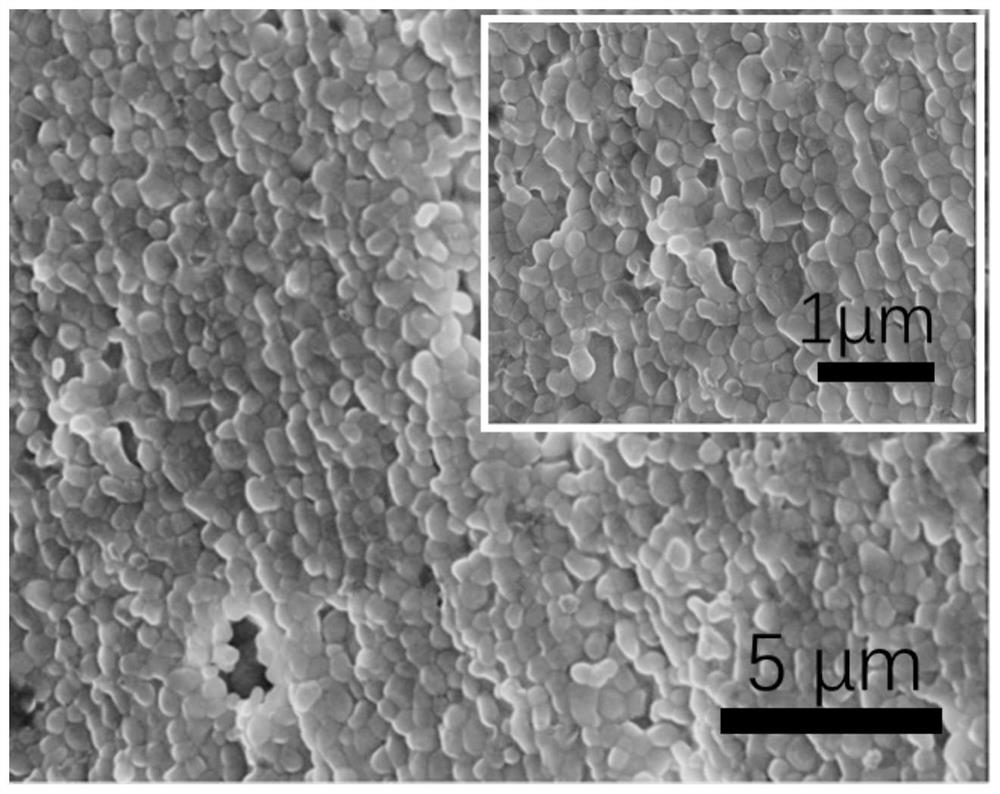

[0031] (3) Solvothermal method-low temperature vulcanization: use the substrate pretreated in step (2) as the working substrate, in the ionic liquid-sulfur salt composite electrolytic system prepared in step (1), vulcanize at a temperature of 353K for 2 hours, The vulcanized produc...

Embodiment 2

[0036](1) Preparation of ionic liquid system: select Reline as eutectic ionic liquid, then add 0.0005mol sulfur salt precursor (thiourea) into 50mL Reline, and get ionic liquid-sulfur salt composite after fully stirring and mixing electrolytic system;

[0037] (2) Substrate surface treatment: take silver sheet (1.5cm×1.5cm×0.05cm) as substrate, soak in dilute sulfuric acid (concentration is 2M dilute sulfuric acid for 15min), absolute ethanol (concentration is 95% absolute ethanol) 10 min), dilute sulfuric acid immersion (concentration is 1% dilute sulfuric acid immersion 10min), deionized water rinse to treat the surface of the substrate;

[0038] (3) Using the surface pretreated substrate in step (2) as the working substrate, in the ionic liquid-sulfur salt composite electrolytic system prepared in step (1), at a temperature of 353K and vulcanized for 2 hours, the vulcanized product was subjected to dehydrated alcohol, After washing with deionized water and drying, a silver...

Embodiment 3

[0040] (1) Preparation of ionic liquid system: choose Glyceline as eutectic ionic liquid, then add 0.00005 mol of sulfur salt precursor (thiourea) into 5 mL of Glyceline, stir and mix well to obtain ionic liquid-sulfur salt composite electrolytic system;

[0041] (2) Substrate surface treatment: take silver wire (φ=0.1cm) as the substrate, soak in dilute sulfuric acid (1% dilute sulfuric acid for 15 minutes), absolute ethanol (95% ethanol for 10 minutes), Soak in dilute sulfuric acid (concentration is 1% dilute sulfuric acid soak for 10min), rinse with deionized water to clean the substrate surface;

[0042] (3) Using the surface pretreated substrate in step (2) as the working substrate, in the ionic liquid-sulfur salt composite electrolytic system prepared in step (1), at a temperature of 353K and vulcanized for 2 hours, the vulcanized product was passed through absolute ethanol 1. Rinse with deionized water, and after drying, a silver sulfide film can be obtained on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com