Deoxidizing agent for stainless steel

A deoxidizer, stainless steel technology, applied in the field of metallurgy, can solve problems such as affecting the surface gloss of stainless steel, and achieve the effect of improving irregular structure, improving adsorption performance and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

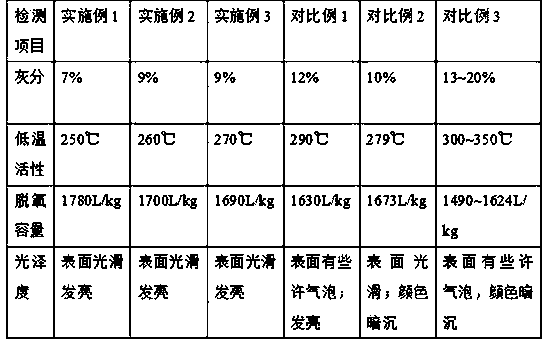

Examples

preparation example Construction

[0028] The preparation method of slow-release deoxygenation microspheres, comprises the steps:

[0029] (1) Mix montmorillonite and solvent A according to the mass ratio of 1:15~25, stir at 350~500r / min for 20~45min, let stand for 30~50min, filter, and take the filter residue with 3~6 times the quality of the filter residue. After washing with deionized water, move to 65~80°C for oven drying until the water content is below 5% to obtain acidified montmorillonite. Take acidified montmorillonite and add dimethylacetamide in a mass ratio of 1:4~6 to mix, and heat up to 80~88℃, vacuumize to remove the water in the system to obtain the pretreated product, take the pretreated product and add isophorone diisocyanate 2~5 times the amount of the pretreated product to mix, stir at 800~1000r / min for 20~40min, then add Mix the caprolactam with 15~30% of the pretreatment substance, homogenize at 1000~1200r / min for 10~25min, get the filler, and set aside;

[0030] (2) Mix starch and deioni...

Embodiment 1

[0037] Additives: tertiary butyl hydroquinone and SiO at a mass ratio of 5:1 2 Mix to get additives.

[0038] Coating solution: mix chitosan with a deacetylation degree of 90% and acetic acid solution with a mass fraction of 8% according to a mass ratio of 1:20, and stir magnetically at 400r / min for 25min to obtain a chitosan solution, calculated in parts by mass , take 40 parts of chitosan liquid, 20 parts of hydroxypropyl methylcellulose, 8 parts of lactose, 10 parts of glycerol triacetate, and 0.2 parts of titanium dioxide, mix them, and disperse them by ultrasonic waves at a frequency of 45 kHz for 10 minutes to obtain a coating solution.

[0039] Solvent A: Mix HCl solution with a concentration of 0.01mol / L and sodium citrate at a mass ratio of 3:1 to obtain Solvent A.

[0040] Solvent B: Mix dopamine solution with a mass concentration of 1.5 g / L and polyvinylpyrrolidone at a mass ratio of 7:1 to obtain solvent B.

[0041] Oil phase: castor oil.

[0042] Adjuvant: Mix ...

Embodiment 2

[0053] Additives: tertiary butyl hydroquinone and SiO at a mass ratio of 8:1 2 Mix to get additives.

[0054] Coating solution: mix chitosan with a deacetylation degree of 90% and acetic acid solution with a mass fraction of 8% according to a mass ratio of 1:30, and stir magnetically at 600r / min for 50min to obtain a chitosan solution, calculated in parts by mass , take 60 parts of chitosan solution, 30 parts of hydroxypropyl methylcellulose, 12 parts of lactose, 15 parts of glycerol triacetate, and 0.6 parts of titanium dioxide, mix them, and disperse them by ultrasonic waves at a frequency of 55 kHz for 15 minutes to obtain a coating solution.

[0055] Solvent A: Mix HCl solution with a concentration of 0.01mol / L and sodium citrate at a mass ratio of 3:2 to obtain Solvent A.

[0056] Solvent B: Mix dopamine solution with a mass concentration of 1.5 g / L and polyvinylpyrrolidone at a mass ratio of 7:3 to obtain solvent B.

[0057] Oil phase: rapeseed oil.

[0058] Adjuvant:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com