Sludge settlement ratio monitoring system and monitoring method thereof

A technology of sludge settling ratio and monitoring system, applied in general control systems, control/regulation systems, closed-circuit television systems, etc., can solve the problems of labor-intensive, sludge position error, low efficiency, etc., to improve efficiency and cleanliness , The effect of low labor cost and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

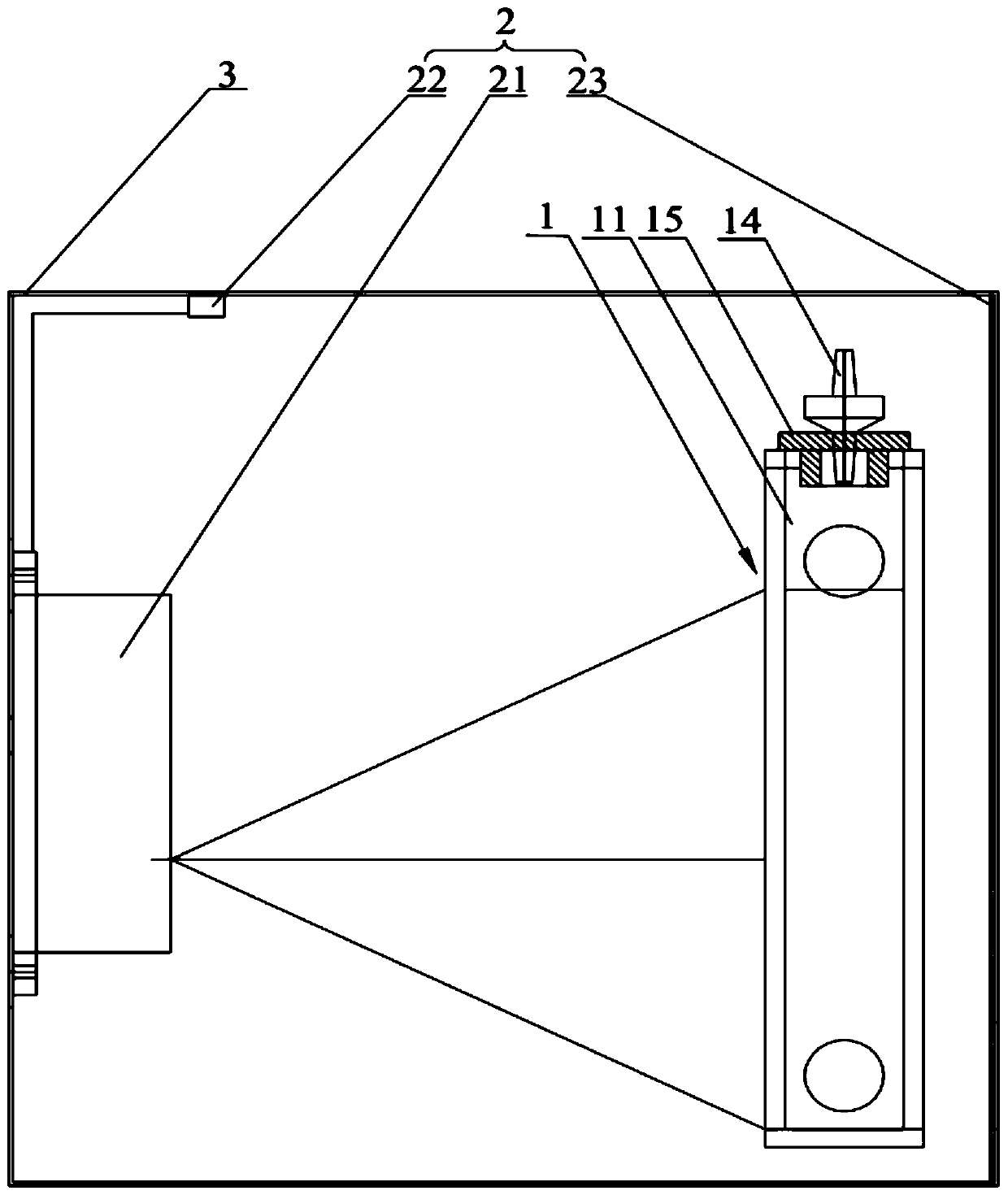

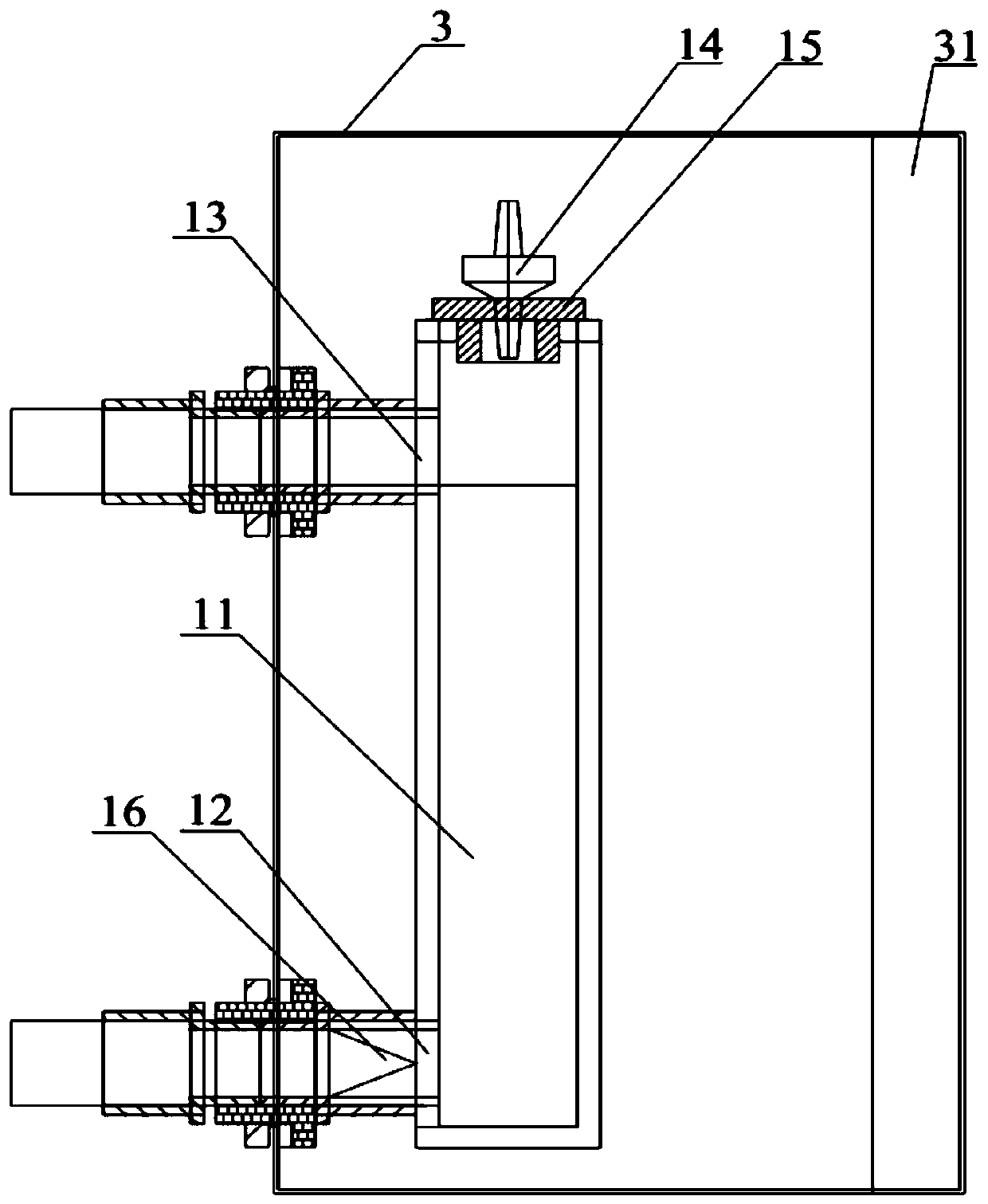

[0052] Such as figure 1 and figure 2As shown, the sludge sedimentation ratio monitoring system provided in this embodiment includes a housing 3, an automatic sampling device 1, an image acquisition device 2 and a data processing and storage device 4, the automatic sampling device 1 includes a measuring cylinder 11; the image acquisition device 2 includes Camera, the camera is arranged on the housing 3, the camera is arranged opposite to the measuring cylinder 11, the horizontal plane where the scale corresponding to 1 / 2 of the sampling volume in the measuring cylinder 11 is the first horizontal plane, and the central axis of the camera lens is in the first horizontal plane; The processing and storage device 4 is used for analyzing and calculating the image collected by the image collecting device 2 . In this embodiment, a side door 31 is provided on one side of the casing 3 to facilitate the installation and maintenance of the automatic sampling device 1 and the image acquis...

Embodiment 2

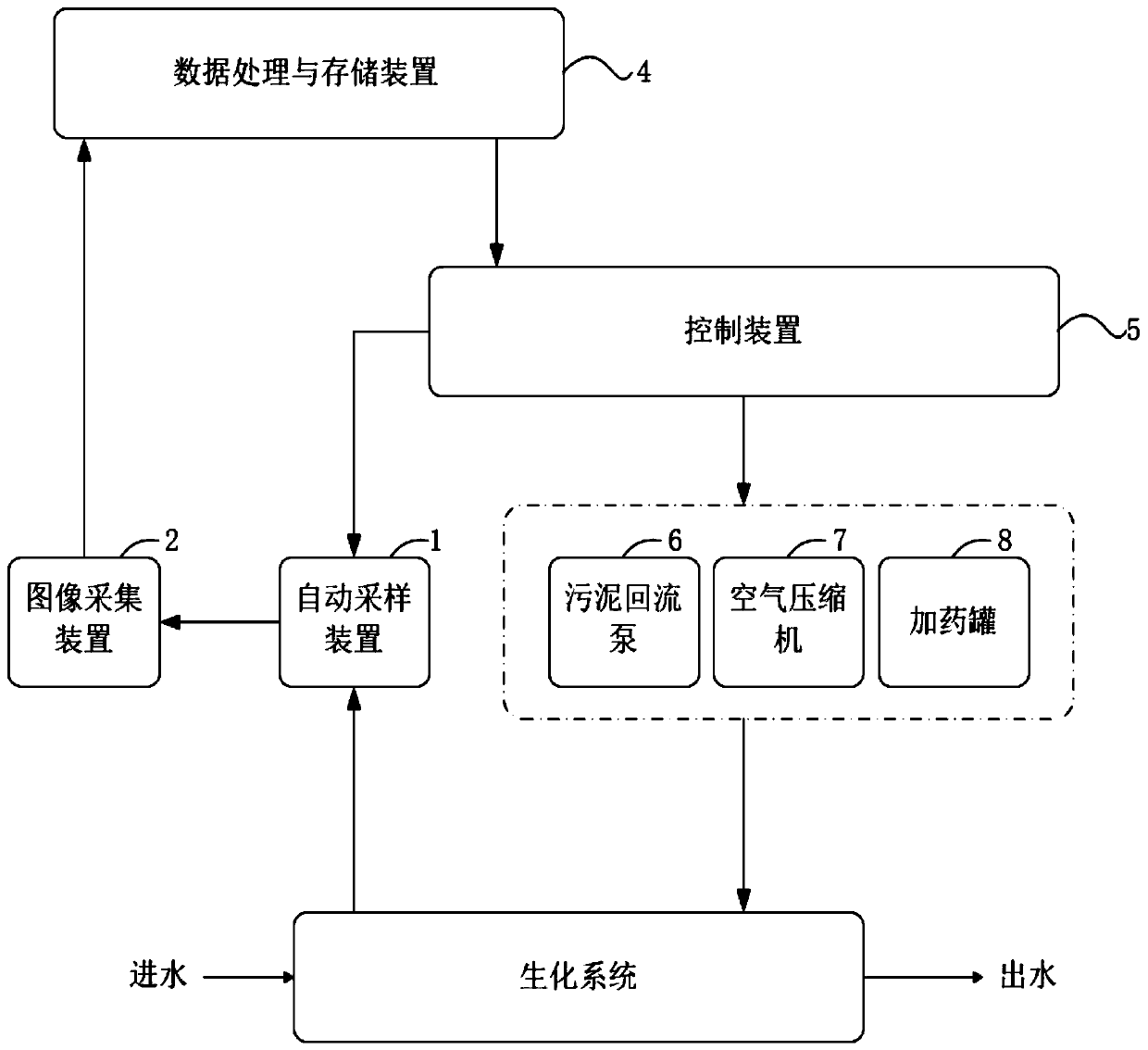

[0080] Such as Figure 7 As shown, this embodiment is based on the sludge sedimentation ratio monitoring method provided in Example 1, adding the step of judging whether the sludge sedimentation ratio is less than the set range. The sludge sedimentation ratio monitoring method provided in this embodiment includes The following steps:

[0081] S1. Control sewage for biochemistry;

[0082] The biochemical system in the sewage treatment integrated equipment biochemically performs the biochemical process on the sewage, and the biochemical process includes adding chemicals through the dosing tank 8 and adjusting the aeration time through the air compressor 7 .

[0083] S2. The automatic sampling device 1 samples the sewage in the biochemical system;

[0084] S3. After the water sample is left standing in the measuring cylinder 11 for a preset time, the image acquisition device 2 takes pictures of the water sample and transmits the image to the data processing and storage device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com