Tension wheel spinning production process

A production process and tensioner technology, which is applied in the field of tensioner spinning production process, can solve problems such as waste of raw materials, and achieve the effects of avoiding waste, reducing cutting processes and facilitating molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

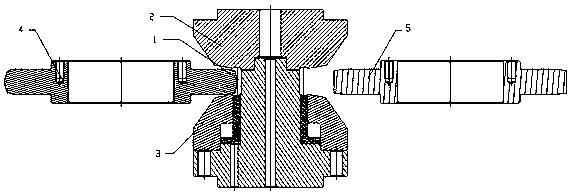

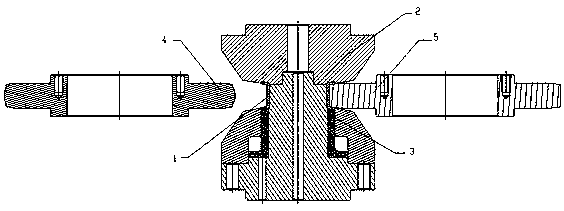

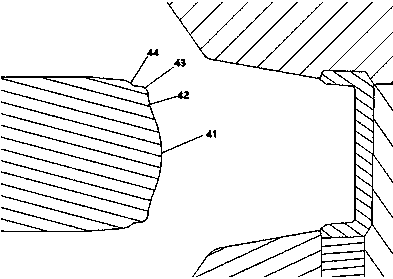

[0024] Such as Figure 1 to Figure 3 A tensioner spinning production process is shown, and the specific production process is as follows:

[0025] S1: blanking: blank the cold-drawn seamless steel pipe according to the specified length to obtain the part blank 1;

[0026] S2: Preforming: Clamp the part blank 1 with the upper forming die 2 and the lower forming die 3, and the inner wall of the part blank 1 is closely attached to the outer contour of the upper forming die 2 and the lower forming die 3, and drives the part blank 1 to rotate And the rotation speed is: 500RPM; at this time, the preforming wheel 4 that has been set outside the edge of the part blank 1 is fed radially along the part blank 1, and the feed speed is: 6mm / s, so that the outer surface of the part is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com