Brick splitting production line and processing technology

A production line and bricklaying technology, which is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of low automation and low production efficiency, and achieve the effect of improving production efficiency and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with accompanying drawing:

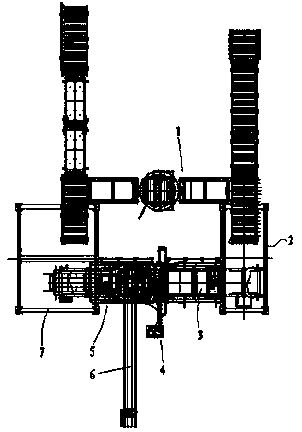

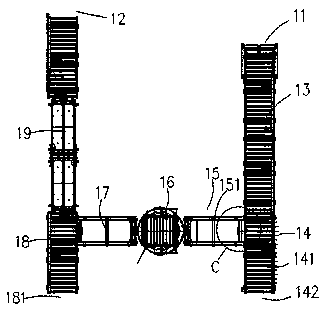

[0062] like Figure 1-25 As shown, this embodiment provides a bricklaying splitting production line, including a pallet circulation system 1, a first brickhanging device 2, a front bricklaying conveying system 3, a bricklaying splitting machine 4, a rear bricklaying conveying system 5, Waste collection system 6 and second brick hanging device 7.

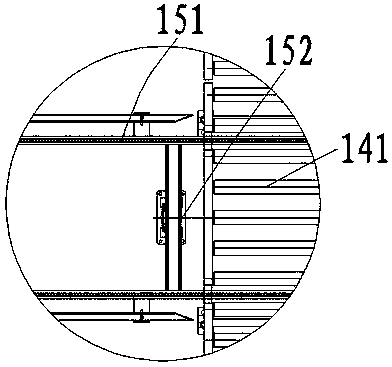

[0063] The bricklaying splitting machine 4 is installed between the front bricklaying conveying system 3 and the rear bricklaying conveying system 5, and the bricklaying splitting machine 4 has a brick splitting work position 86, and the bricklaying splitting machine 4 includes an inner frame 821, an outer frame 822, the main driver 84, the upper knife assembly 81, the lower knife assembly 85, the elastic support assembly 823 and the guide, the main driver 84 is installed at the upper end of the inner frame 821, and the lower kni...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap