Method for improving chloride type salt pan production efficiency and chloride type salt pan product

A production efficiency, chloride technology, applied in the field of salt fields, can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] In brine containing only potassium chloride and sodium chloride (concentration 0.5g / L, 2.3g / L), the evaporation efficiency of brine is at room temperature, refrigerator (-18℃), blast drying (35℃), drying (35℃) ) conditions were 0.1017kg / (m2·h), 0.010; kg / (m2·h), 0.749kg / (m2·h) and 0.05488kg / (m2·h), respectively. Compared with potassium chloride + sodium chloride + magnesium chloride (concentration 0.5g / L, 2.3g / L, 90g / L), potassium chloride + sodium chloride + half of magnesium chloride (concentration 0.5g / L, 2.3g / L) , 45g / L), potassium chloride + sodium chloride + more than half of magnesium chloride (concentration 0.5g / L, 2.3g / L, 135g / L), the evaporation efficiency is much higher. Therefore, the brine was treated under different experimental conditions to improve the evaporation efficiency.

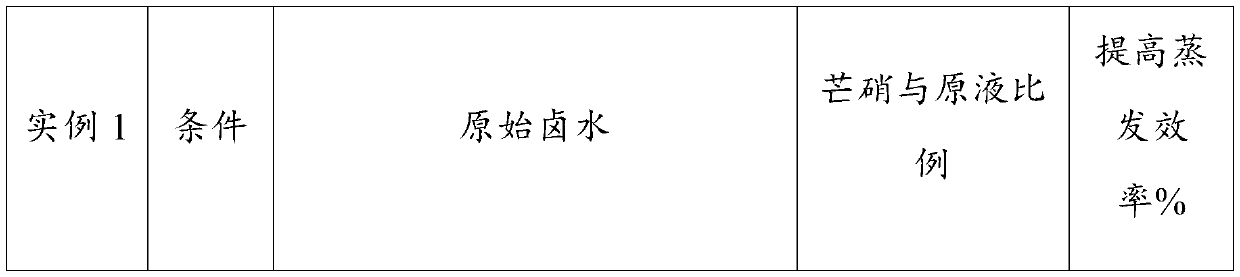

[0077] At room temperature, in potassium chloride + sodium chloride + magnesium chloride (concentration 0.5g / L, 2.3g / L, 90g / L), potassium chloride + sodium chloride + less than h...

Embodiment 2

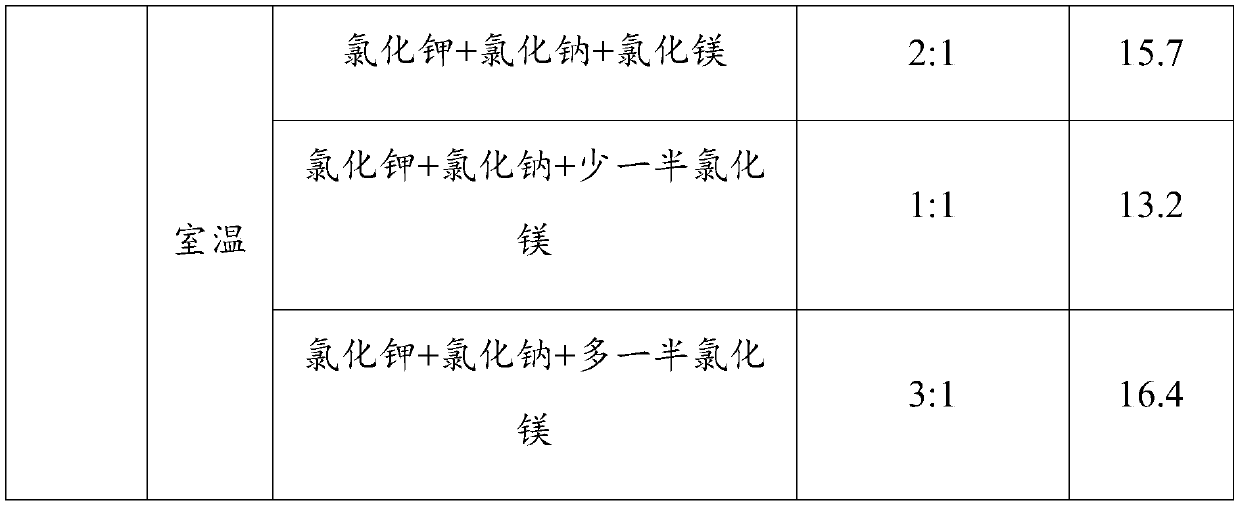

[0082] Under the condition of refrigerator (-18℃), in potassium chloride + sodium chloride + magnesium chloride (concentration 0.5g / L, 2.3g / L, 90g / L), potassium chloride + sodium chloride + less than half of magnesium chloride (concentration 0.5g / L) g / L, 2.3g / L, 45g / L), potassium chloride + sodium chloride + more than half of magnesium chloride brine (concentration 0.5g / L, 2.3g / L, 135g / L), then add Glauber's salt solution, Glauber's salt solution and The molar mass ratios of the original brine were 1:1, 2:1 and 3:1, respectively. The evaporation efficiency improvement ratio is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com