Manufacturing device for working mode band of micro-pyramid arraying structure and manufacturing method for manufacturing device

A technology of array structure and manufacturing method, which is applied in the field of micro-pyramid array structure working mold belt manufacturing, can solve the problems affecting the frequency of repeated use of the master mold, the easy distortion and deformation of the master mold when it is opened, and the gap width at the splicing part. Increase the frequency of reuse, improve the quality level, and improve the effect of patchwork quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

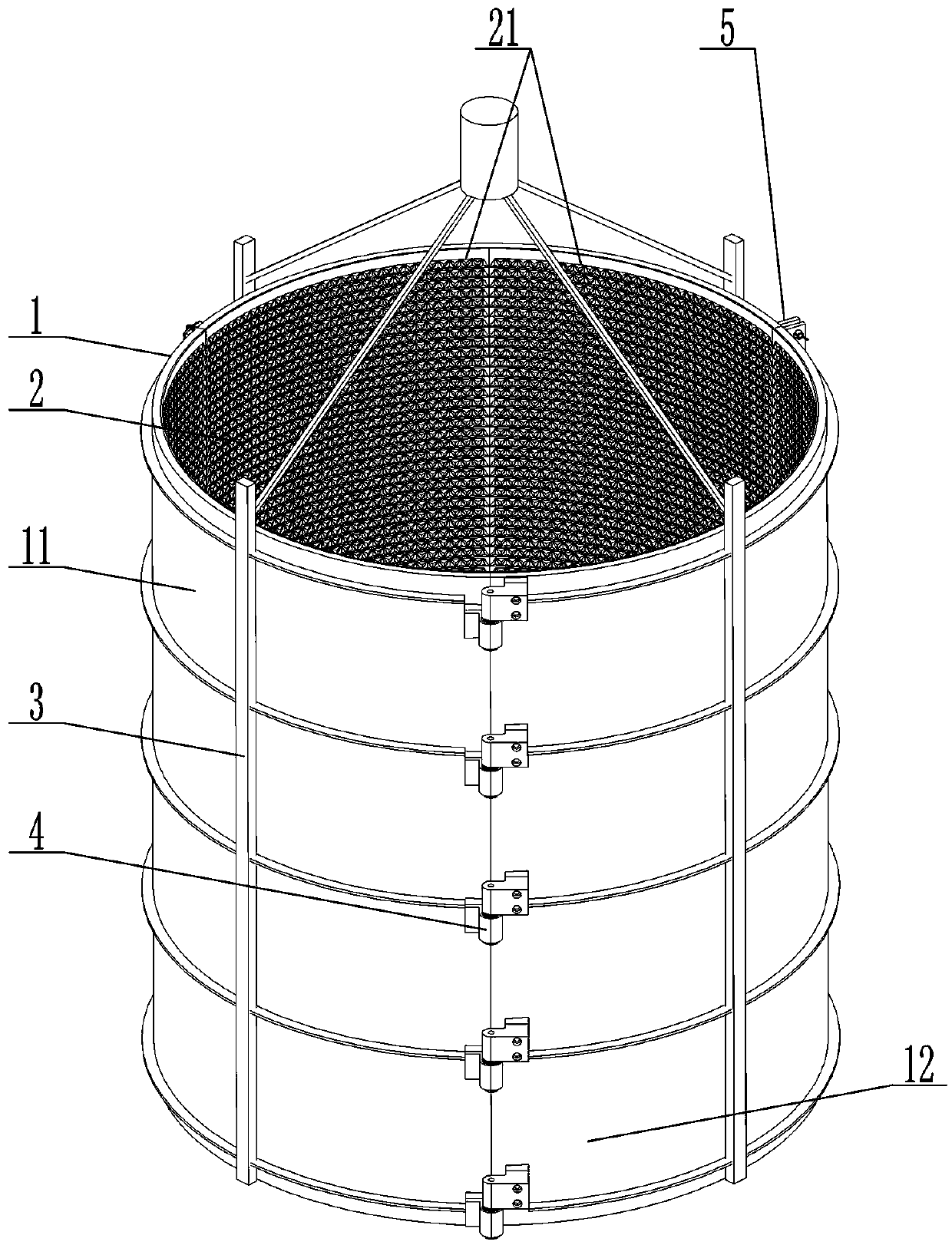

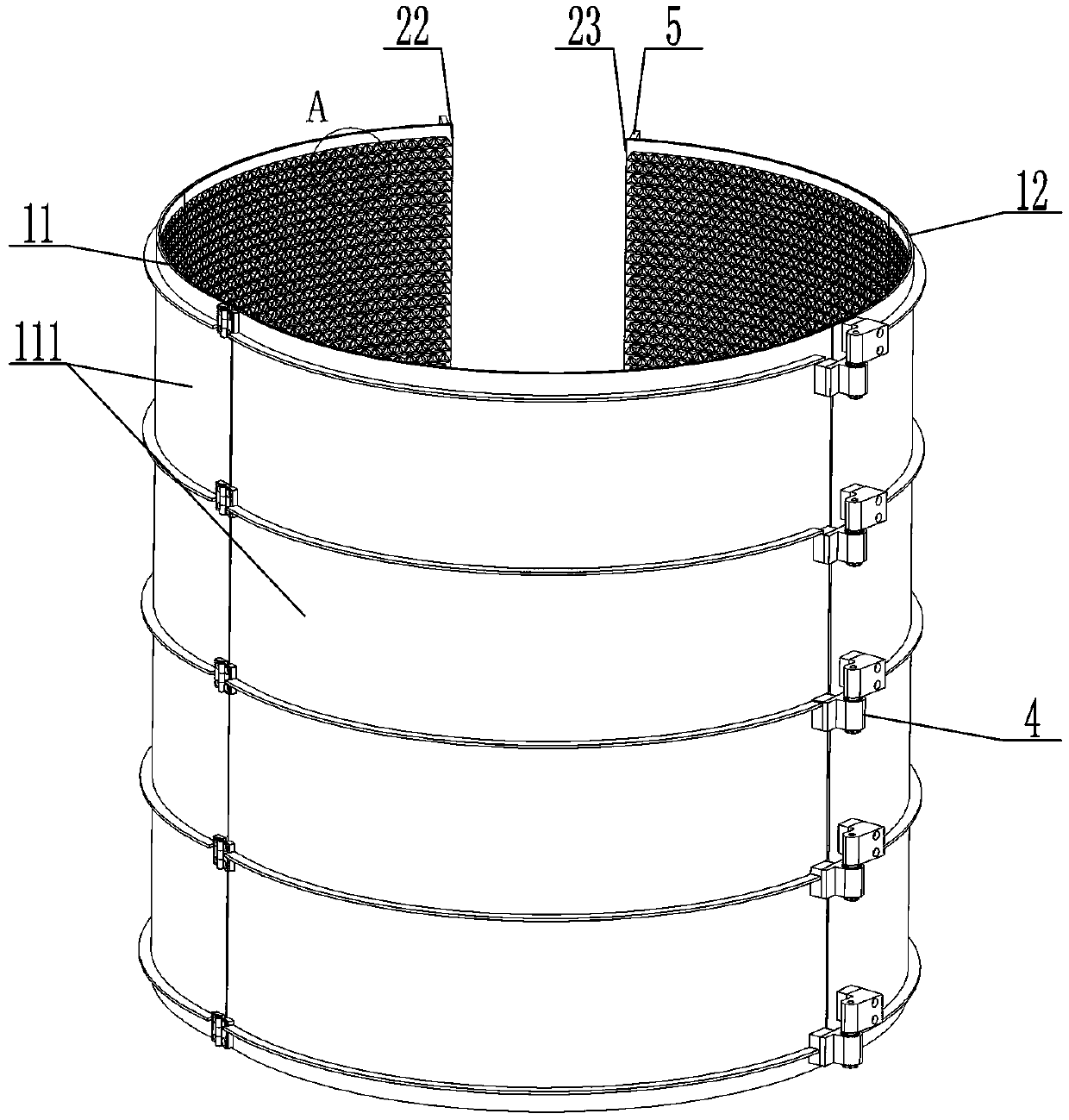

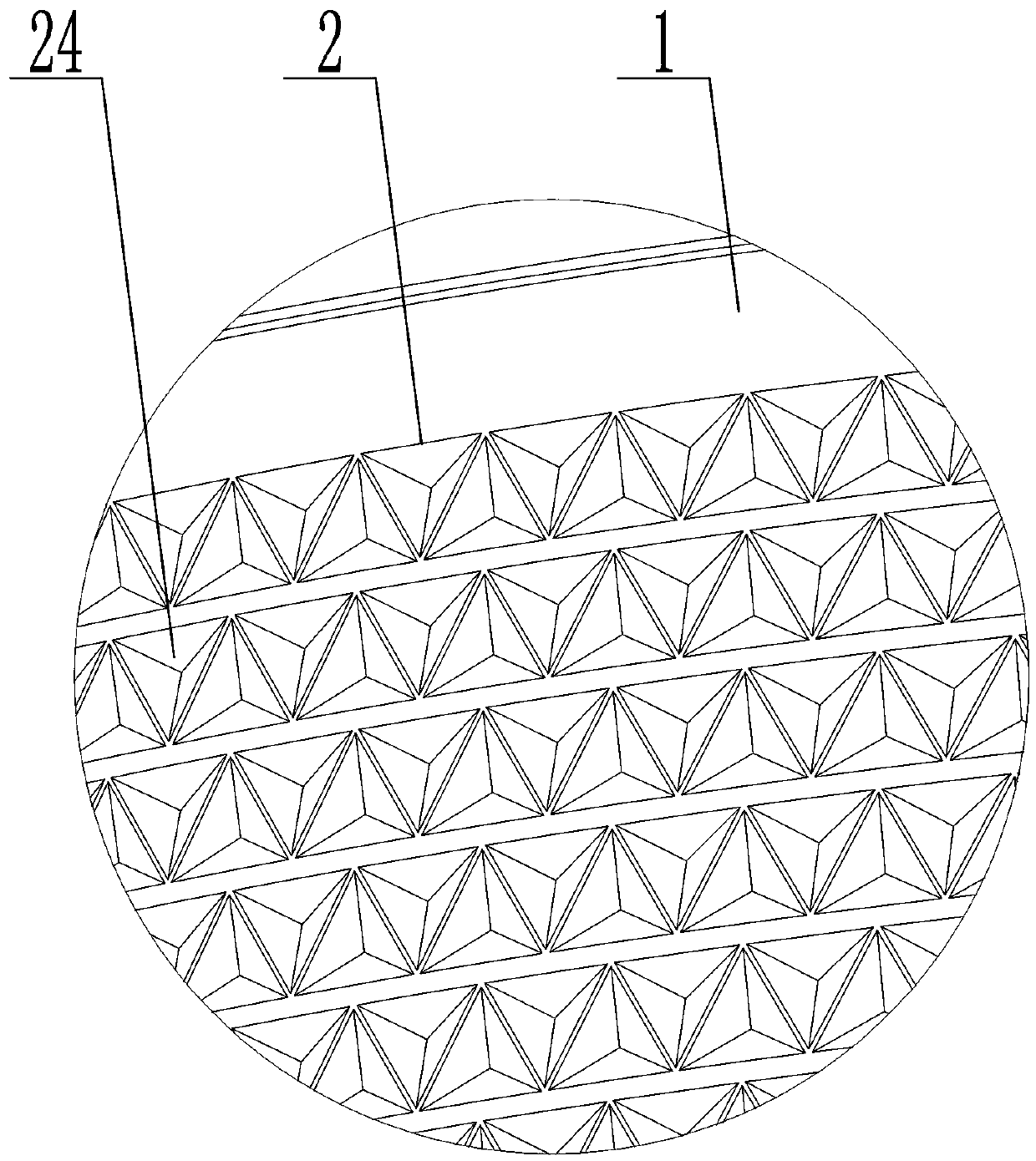

[0057] Such as Figure 1 to Figure 8 As shown, a device for manufacturing a micropyramid array structure working mold belt includes a cylinder 1 and a master mold 2. The master mold 2 is arranged on the inner surface of the cylinder 1, and the master mold 2 is facing away from the cylinder. One side of the inner surface of 1 is provided with a micropyramid array structure 24. The cylinder 1 includes a first arc-shaped support plate 11, a second arc-shaped support plate 12, a hinge 4, and a locking device 5. The first One end of an arc-shaped support plate 11 and one end of the second arc-shaped support plate 12 are rotatably connected by the hinge 4, and the other end of the first arc-shaped support plate 11 and the other end of the second arc-shaped support plate 12 are connected by The locking device 5 is connected and locked, and the female mold 2 is provided with a first opening and closing edge 22 corresponding to the end of the first arc-shaped support plate 11 provided ...

Embodiment 2

[0085] The thickness of the first arc-shaped support plate 11 and the second arc-shaped support plate 12 is 30mm.

[0086] The cylinder 1 has a diameter of 1500mm and a height of 1700mm.

[0087] The master mold 2 is a thin plate made of nickel with a thickness of 2mm.

[0088] The cylinder 1 obtained in the step a is also rounded by a rounding device, and the roundness of the rounded cylinder 1 is 0.1 mm.

[0089] The inner side of the cylinder 1 obtained in the step a is also polished, and the surface roughness of the polished cylinder 1 is grade 14.

[0090] In the step b, the cutting end faces of the first arc-shaped support plate 11 and the second arc-shaped support plate 12 are subjected to precision trimming, and the roughness of the cutting end faces after the precision trimming is grade 14, straight line The degree is 0.01mm.

[0091] Other implementations are the same as in Example 1.

Embodiment 3

[0093] The thickness of the first arc-shaped support plate 11 and the second arc-shaped support plate 12 is 20mm.

[0094] The cylinder 1 has a diameter of 1000mm and a height of 1150mm.

[0095] The master mold 2 is a thin plate made of nickel with a thickness of 1.1mm.

[0096] The cylinder 1 obtained in the step a is also rounded by a rounding device, and the roundness of the rounded cylinder 1 is 0.05 mm.

[0097] The inner side of the cylinder 1 obtained in the step a is also polished, and the surface roughness of the polished cylinder 1 is grade 10.

[0098] In the step b, the cutting end faces of the first arc-shaped support plate 11 and the second arc-shaped support plate 12 are subjected to precision trimming, and the roughness of the cutting end faces after precision trimming is grade 10, straight line The degree is 0.005mm.

[0099] Other implementations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com