Pulp molding tableware molding and cold-pressing dehydration mesh-free hot drying two-station all-in-one machine

A pulp molding and thermal drying technology, which is applied in the direction of physical treatment of paper, textiles and papermaking, can solve the problems of increased heat energy consumption, complicated molding equipment, inconvenient disassembly and installation of molds, etc., and achieves reduced equipment volume, compact structure, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now described in detail with accompanying drawings as follows. The embodiments described in the accompanying drawings are only used to illustrate the technical solutions of the present invention and are not limiting this invention.

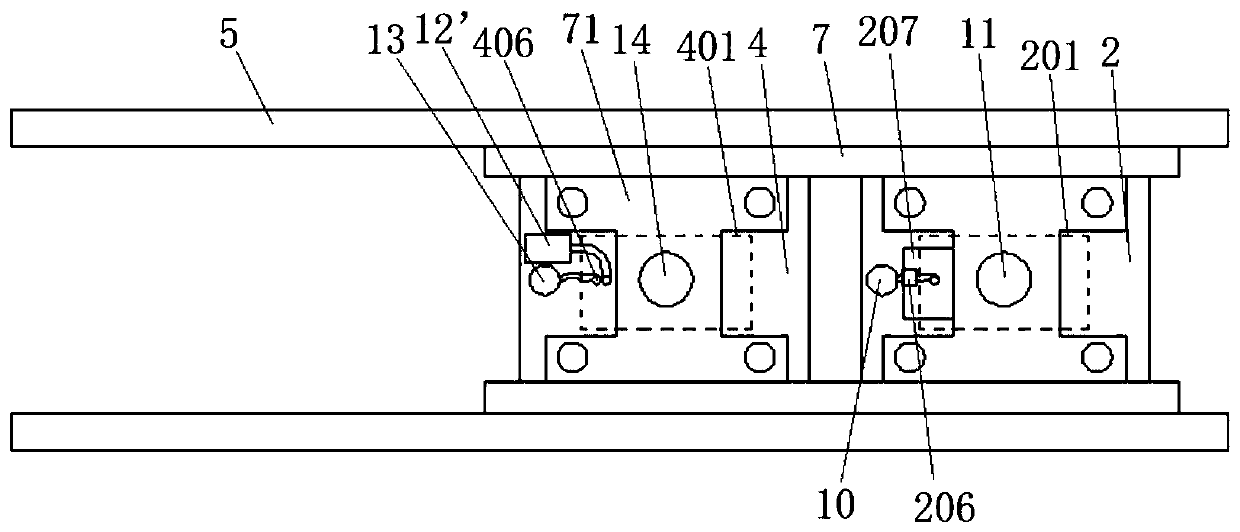

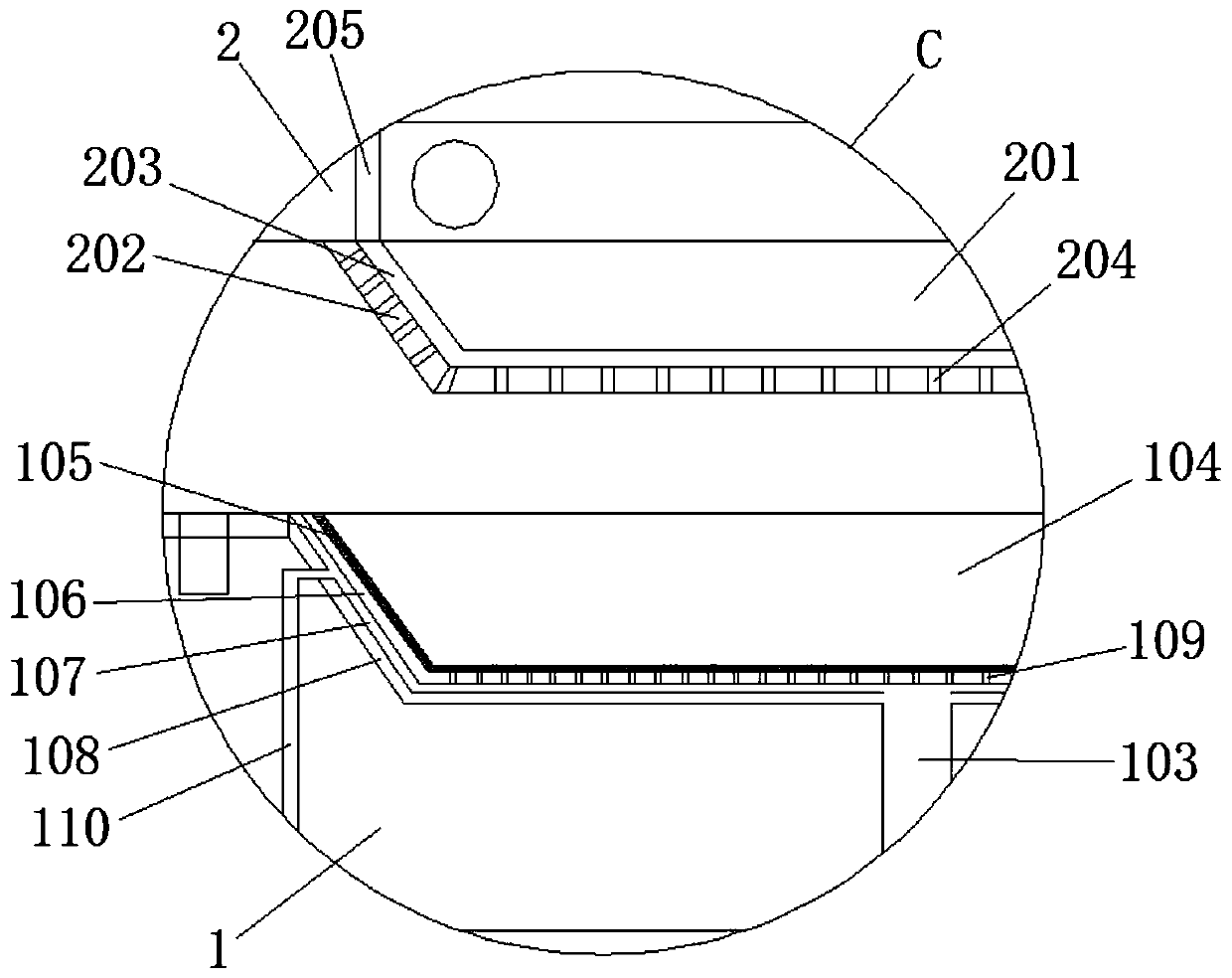

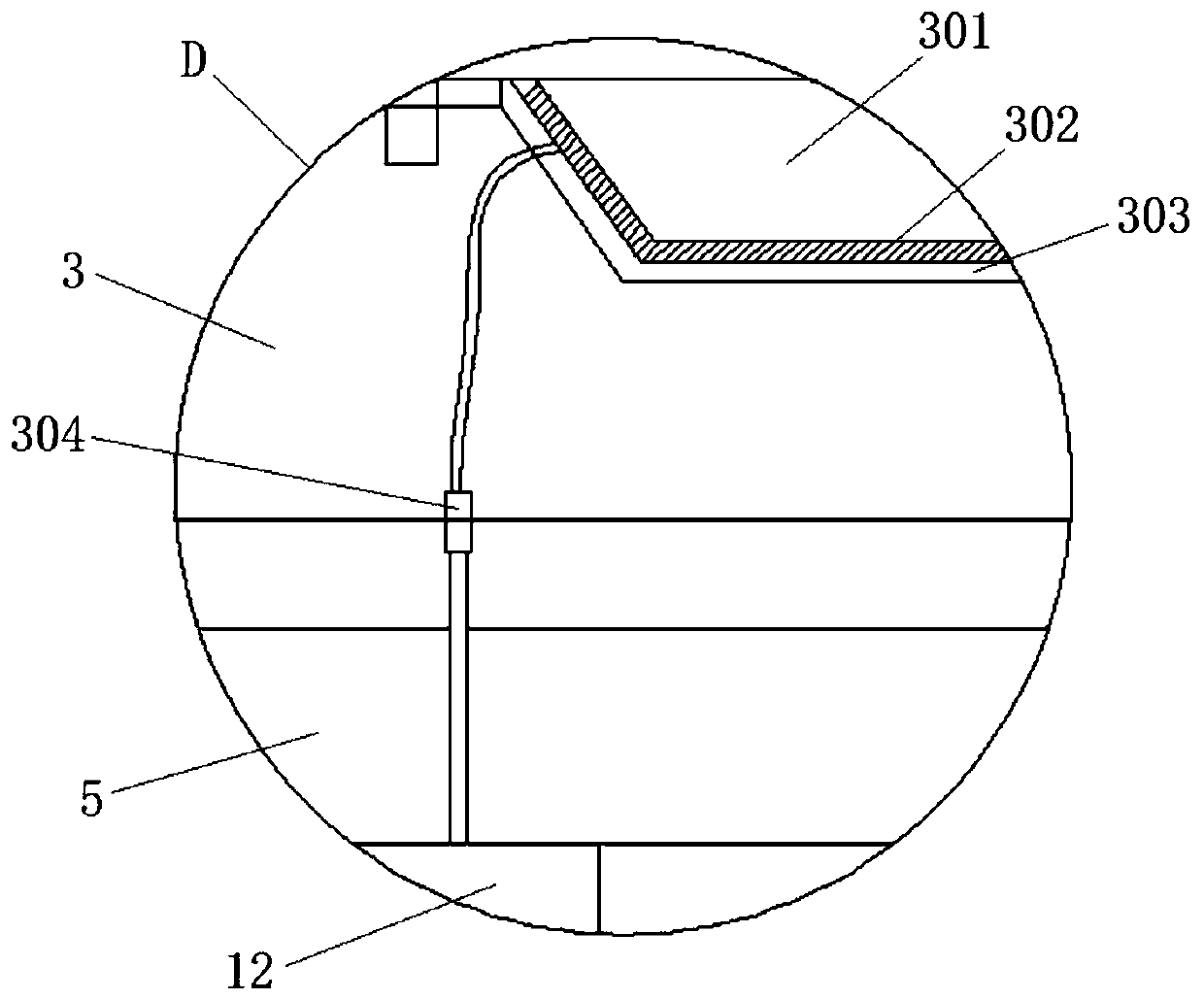

[0029] Such as figure 1 and figure 2 As shown, a two-station all-in-one machine for forming pulp molded tableware with cold pressing and dehydration without net heating and drying, including forming lower mold 1, cold pressing upper mold 2, drying lower mold 3 and drying upper mold 4; forming lower mold 1 Set up at the station A of the frame device 5, the cold pressing upper mold 2 is set up on the frame device 5 above the molding lower mold 1, the drying lower mold 3 is set up at the station B of the frame device 5, and the drying The upper mold 4 is erected on the rack device 5 above the drying lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com