Nano SiC/epoxy coating material, and preparation method and application thereof

An epoxy coating and nano-technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve problems such as power equipment failures, achieve the effects of accelerating charge dissipation, increasing flashover voltage, and efficient methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

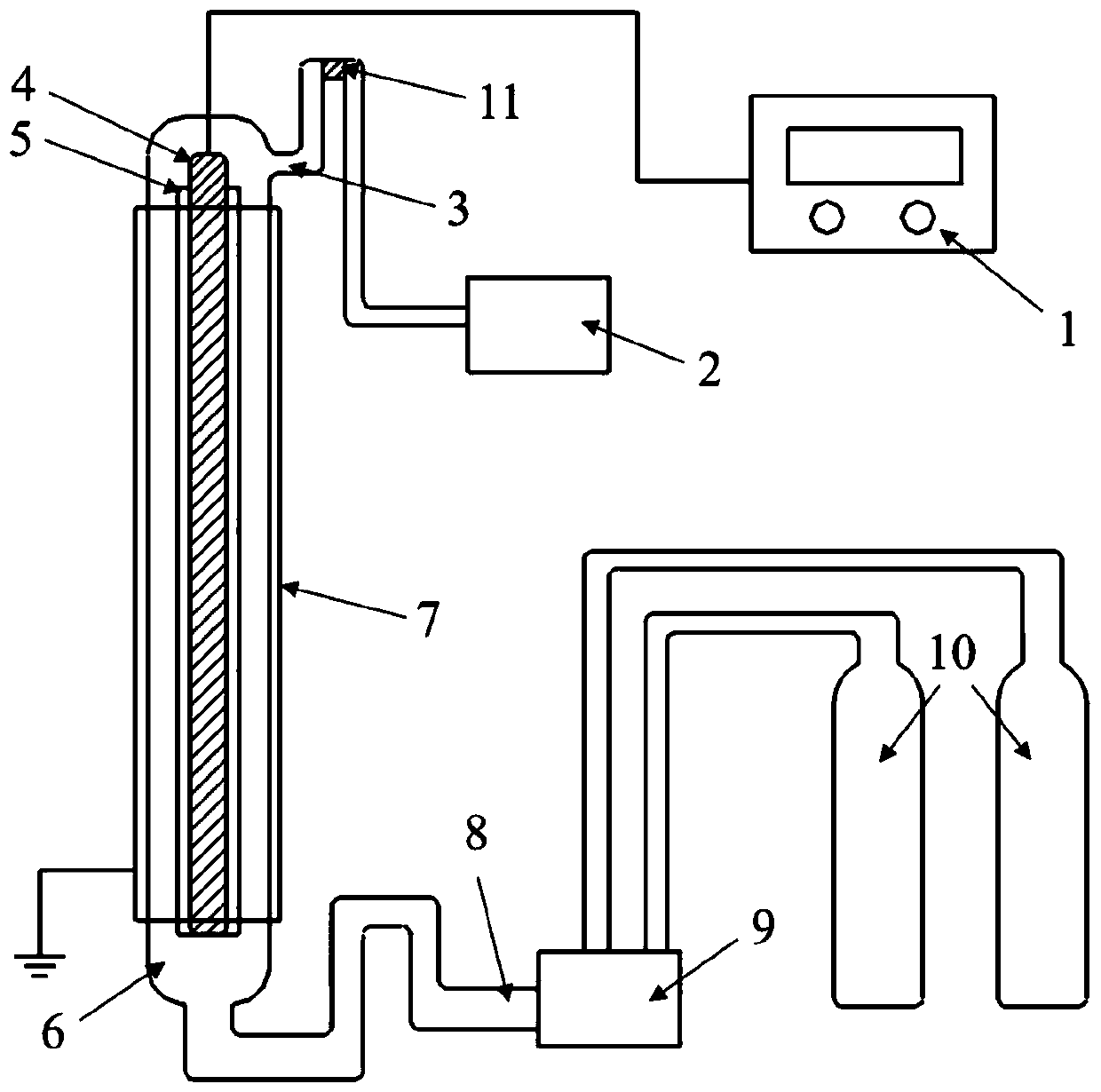

[0032] The preparation method of nano SiC / epoxy coating material, comprises:

[0033] Step 1: Put 5g of nano-SiC into the plasma fluidized bed device for powder treatment, turn on the vacuum pump, keep the chamber pressure at 50-100pa, and sequentially feed CF with a gas flow rate of 1slm 4 And 10slm of Ar, when a stable fluidized bed is formed in the reaction chamber, turn on the high-frequency AC power supply, the voltage is 10-15kV, the current is 10-15mA, and after 10-12min, the nano-SiC treated by plasma fluorination is obtained. .

[0034] Step 2: Add the nano-SiC treated by plasma fluorination to the E51 epoxy resin in an amount of 3% of the mass fraction of the E51 epoxy resin, and stir for 20 to 30 minutes with a vacuum mechanical stirrer with a speed of 1000r / min; Add methyltetrahydrophthalic anhydride curing agent and DMP-30 accelerator to the mixture, and the mass ratio of E51 epoxy resin, methyltetrahydrophthalic anhydride curing agent and DMP-30 accelerator is 1...

Embodiment 2

[0040] The preparation method of nano SiC / epoxy coating material, comprises:

[0041] Step 1: Put 5g of nano-SiC into the plasma fluidized bed device, turn on the vacuum pump, keep the chamber pressure at 50-100pa, and sequentially inject CF with a gas flow rate of 1slm 4 And 10slm of Ar, when a stable fluidized bed is formed in the reaction chamber, turn on the high-frequency AC power supply, the voltage is 10-15kV, the current is 10-15mA, and after 10-12min, the nano-SiC treated by plasma fluorination is obtained. .

[0042] Step 2: Add the nano-SiC treated by plasma fluorination to the E51 epoxy resin in an amount of 5% of the mass fraction of the E51 epoxy resin, and stir for 20 to 30 minutes with a vacuum mechanical stirrer with a speed of 1000r / min; Add methyltetrahydrophthalic anhydride curing agent and DMP-30 accelerator to the mixture, and the mass ratio of E51 epoxy resin, methyltetrahydrophthalic anhydride curing agent and DMP-30 accelerator is 100:85:1; The vacuu...

Embodiment 3

[0044] The preparation method of nano SiC / epoxy coating material, comprises:

[0045] Step 1: Put 5g of nano-SiC into the plasma fluidized bed device, turn on the vacuum pump, keep the chamber pressure at 50-100pa, and sequentially inject CF with a gas flow rate of 1slm 4 And 10slm of Ar, when a stable fluidized bed is formed in the reaction chamber, turn on the high-frequency AC power supply, the voltage is 10-15kV, the current is 10-15mA, and after 10-12min, the nano-SiC treated by plasma fluorination is obtained. .

[0046] Step 2: Add the nano-SiC treated by plasma fluorination to the E51 epoxy resin in an amount of 8% of the mass fraction of the E51 epoxy resin, and stir for 20 to 30 minutes with a vacuum mechanical stirrer with a speed of 1000r / min; Add methyltetrahydrophthalic anhydride curing agent and DMP-30 accelerator to the mixture, and the mass ratio of E51 epoxy resin, methyltetrahydrophthalic anhydride curing agent and DMP-30 accelerator is 100:85:1; The vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com