Corrosion-resistance composite metal material and preparation method thereof

A composite metal material and corrosion-resistant technology, applied in the field of metal materials, can solve the problems of aluminum-based composite materials being susceptible to corrosion, etc., and achieve the effects of improving hardness and wear resistance, improving corrosion resistance, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

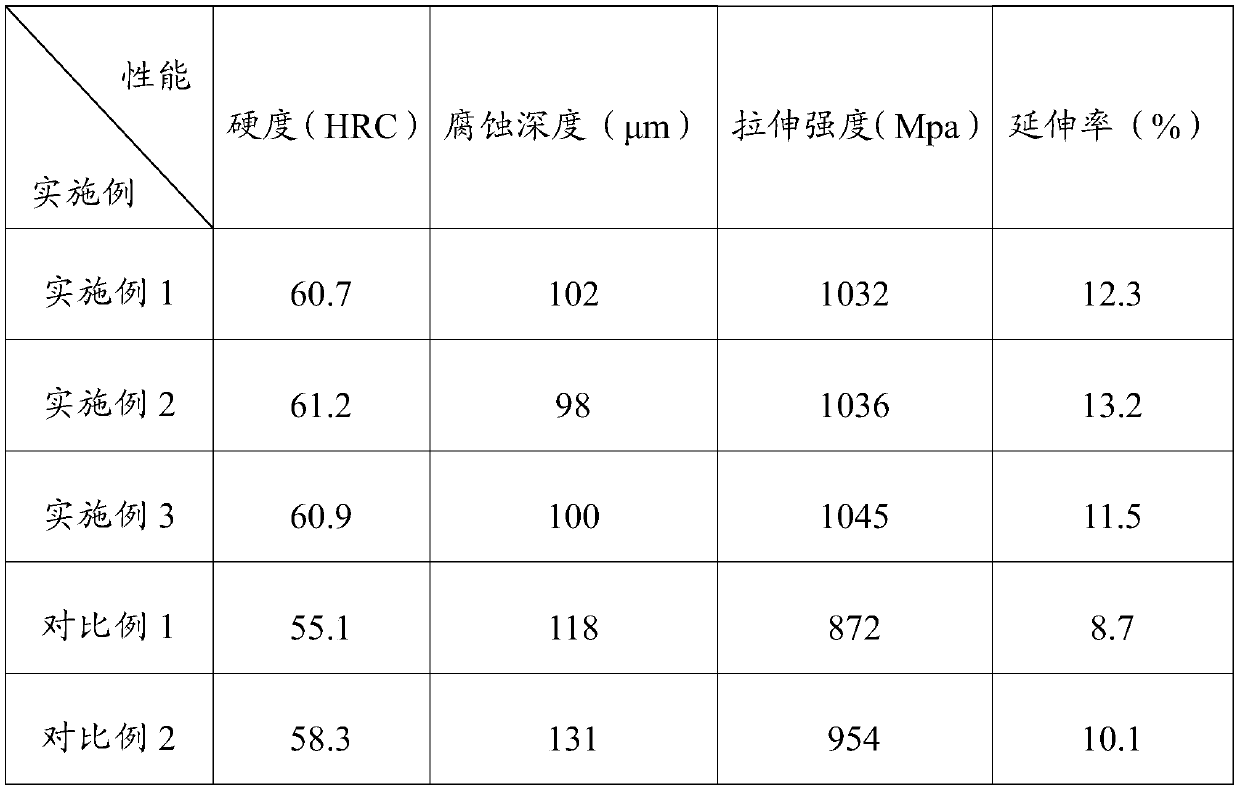

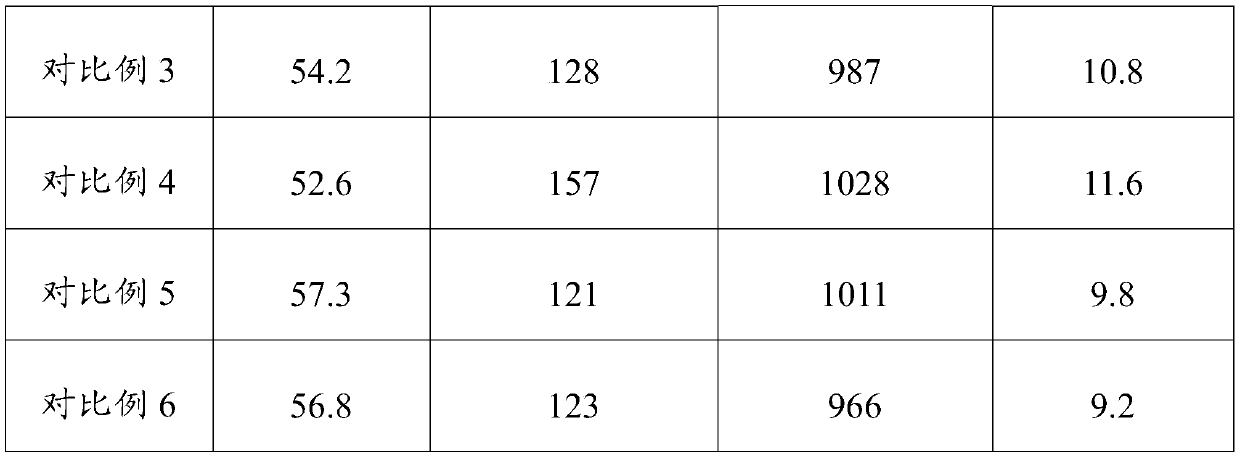

Examples

Embodiment 1

[0028] A corrosion-resistant composite metal material made of the following components in mass percentage: Mn: 1.5%, Ti: 0.8%, Ca: 0.90%, La: 0.6%, Ni: 0.4%, Y: 0.06%, basalt 0.8% %, the balance is made up 100% with Al;

[0029] Specifically follow the steps below:

[0030] Step 1, weighing Mn: 1.5%, Ti: 0.8%, Ca: 0.90%, La: 0.6%, Ni: 0.4%, Y: 0.06%, basalt 0.8% according to the mass percentage, and make up 100% with Al;

[0031] Step 2, mixing the La, Y and basalt weighed in step 1 to obtain a mixed raw material A, adding water equal to the quality of the mixed raw material A to the mixed raw material A and performing ball milling to obtain a mixed powder A with a fineness of 250 mesh;

[0032] Step 3, put the mixed powder A in a vacuum intermediate frequency induction furnace, and the vacuum degree is 1×10 -3 Pa, smelting temperature is 1120 ℃ under the condition of smelting for 2h to obtain the alloy;

[0033] Step 4, mixing the Mn, Ti, Ca, Ni, Al obtained in step 1 and ...

Embodiment 2

[0037] A corrosion-resistant composite metal material made of the following components in mass percentage: Mn: 1.0%, Ti: 0.5%, Ca: 1.0%, La: 0.5%, Ni: 0.5%, Y: 0.05%, basalt 1.0% %, the balance is made up 100% with Al;

[0038] Specifically follow the steps below:

[0039] Step 1, weighing Mn: 1.0%, Ti: 0.5%, Ca: 1.0%, La: 0.5%, Ni: 0.5%, Y: 0.05%, basalt 1.0% according to the mass percentage, and make up 100% with Al;

[0040] Step 2, mixing the La, Y and basalt weighed in step 1 to obtain a mixed raw material A, adding water equal to the quality of the mixed raw material A to the mixed raw material A and performing ball milling to obtain a mixed powder A with a fineness of 300 meshes;

[0041] Step 3, put the mixed powder A in a vacuum intermediate frequency induction furnace, and the vacuum degree is 1×10 -3 Pa, smelting temperature is 1200 ℃ under the condition of smelting for 1h to obtain the alloy;

[0042] Step 4, mixing the Mn, Ti, Ca, Ni, Al obtained in step 1 and ...

Embodiment 3

[0046]A corrosion-resistant composite metal material made of the following components in mass percentage: Mn: 1.2%, Ti: 1.0%, Ca: 0.5%, La: 0.8%, Ni: 0.3%, Y: 0.08%, basalt 0.5% %, the balance is made up 100% with Al;

[0047] Specifically follow the steps below:

[0048] Step 1, weigh Mn: 1.2%, Ti: 1.0%, Ca: 0.5%, La: 0.8%, Ni: 0.3%, Y: 0.08%, basalt 0.5% according to mass percentage, and make up 100% with Al;

[0049] Step 2, mixing the La, Y and basalt weighed in step 1 to obtain a mixed raw material A, adding water equal to the quality of the mixed raw material A to the mixed raw material A and performing ball milling to obtain a mixed powder A with a fineness of 300 meshes;

[0050] Step 3, put the mixed powder A in a vacuum intermediate frequency induction furnace, and the vacuum degree is 1×10 -3 Melting for 1.5h under the conditions of Pa and melting temperature of 1250°C to obtain the alloy;

[0051] Step 4, mixing the Mn, Ti, Ca, Ni, Al obtained in step 1 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com