Connecting mechanism of expansion and contraction device

A technology of telescopic device and connecting mechanism, which is applied to bridge parts, bridges, buildings, etc., can solve problems such as complicated construction, delayed construction time, high labor intensity, etc., so as to speed up the progress of paving construction, improve the reliability of connection, and speed up cleaning speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the examples, but it should not be interpreted as a limitation of the present invention. The protection scope of the present invention is based on the contents recorded in the claims. protection scope of the present invention.

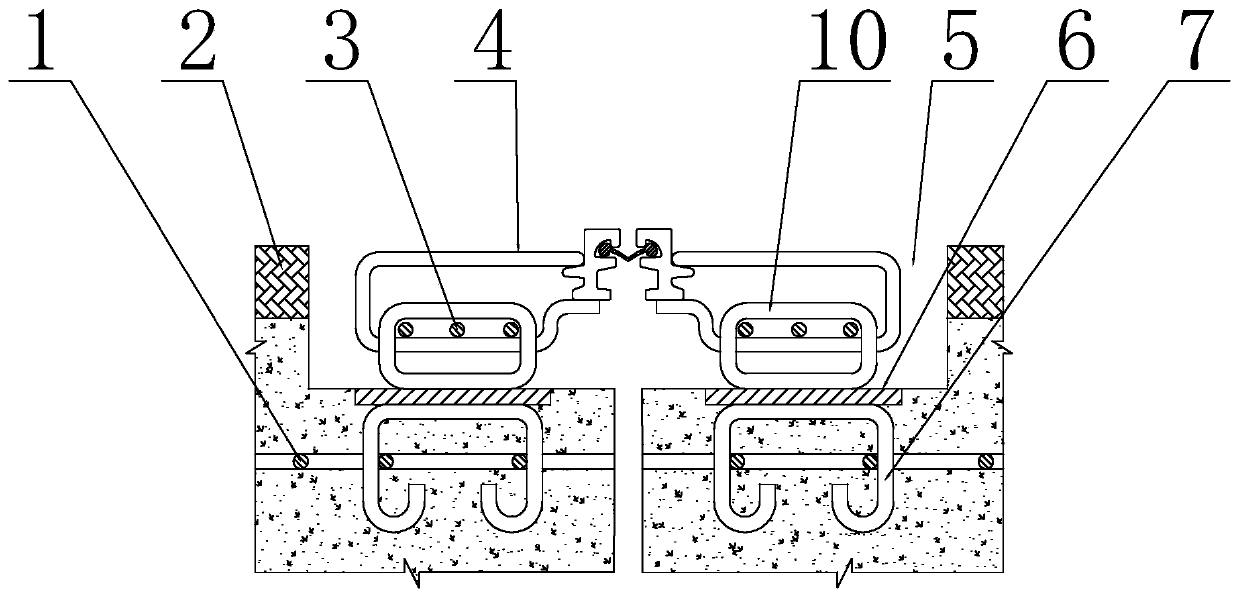

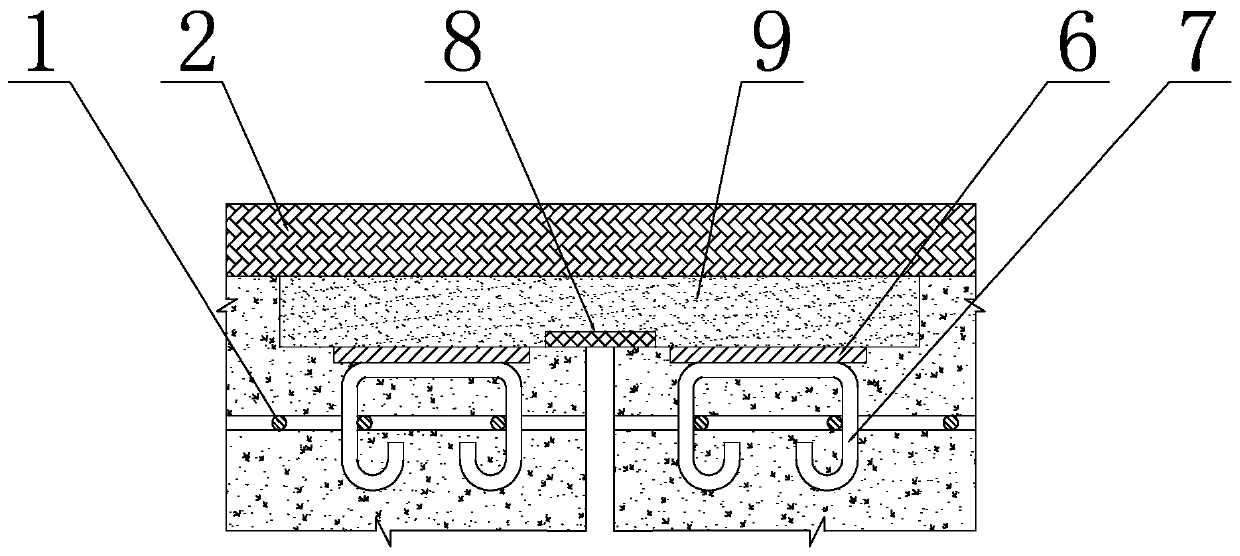

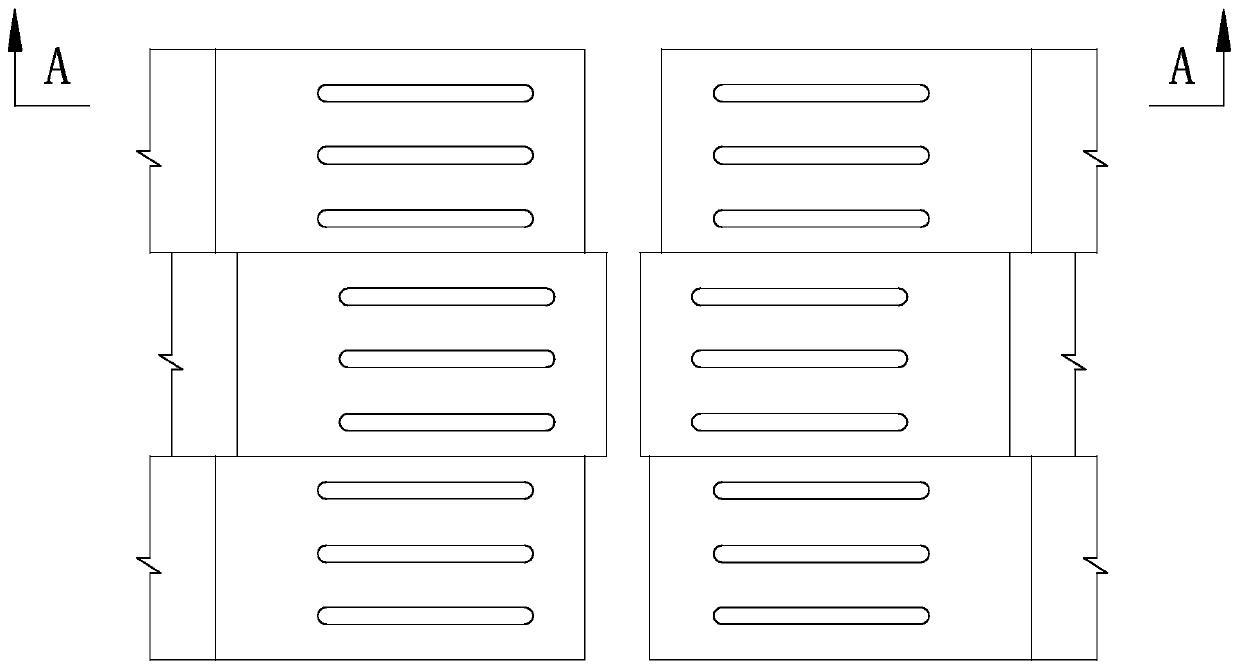

[0060] The overall structure of this embodiment is as shown in the figure. The connecting mechanism of the telescopic device includes pre-buried in the concrete structure at the bottom of the reserved groove 5 opened at the beam end or the bridge head at intervals, and is assembled with the anchor rib 4 of the telescopic device through the lap rib 10. The embedded part 7; the embedded part 7 is embedded in the concrete structure at the bottom of the reserved groove 5 as a whole, the top of the embedded part 7 is not higher than the bottom surface of the inner cavity of the reserved groove 5, and the top of the embedded part 7 includes anchor ribs 4 An assembly part that fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com