Bridge-plug-free immovable string casing damaged well chemical plugging technology

A technology for moving tubes and casings, applied in the directions of chemical instruments and methods, wellbore/well components, drilling compositions, etc., to achieve the effects of reducing risks, avoiding cost and time, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

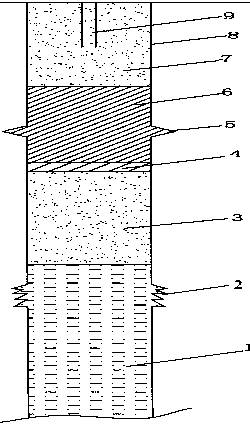

Image

Examples

Embodiment 1

[0036] This embodiment provides a chemical plugging process for a casing damaged well without a bridge plug, including the following steps:

[0037] Step 1) Test the water absorption of casing damaged section under 10MPa pressure, and select wells with water absorption less than 200L / min for plugging;

[0038] Step 2) Run the varnish tubing into the casing of the casing damaged well 200 meters above the casing damage section, and close the casing gate;

[0039] Step 3) After injecting the guar gum liquid, it naturally sinks to the bottom of the well for 20-30 minutes, and the production layer is blocked to keep the liquid level unchanged. Inject clean water until the clean water level is 10-15 meters away from the lower edge of the casing damage section;

[0040] Step 4) After injecting the organic resin plugging agent system, settle naturally for 20-30 minutes to form the first resin plug, and shut down the well;

[0041] Step 5) Prepare the organic resin plugging agent syst...

Embodiment 2

[0045] This embodiment provides a chemical plugging process for a casing damaged well without a bridge plug, including the following steps:

[0046] Step 1) Use a conventional packer to test the water absorption of the casing damaged section of the casing damaged well under a pressure of 10MPa, and select the well with a water absorption of less than 200L / min for plugging;

[0047] Step 2) Run the varnish tubing into the casing of the casing damaged well 200 meters above the casing damage section, and close the casing gate;

[0048] Step 3) Prepare and inject 300-400L of guar gum solution with a mass concentration of 0.35-0.55%, let it sink naturally for 20-30 minutes to the bottom of the well, and plug the production layer, keep the liquid level constant, inject clean water, and calculate the amount of clean water, so that The clear water level is located 10-15 meters away from the lower edge of the casing damage section;

[0049] Step 4) Prepare and inject 100-200L organic ...

Embodiment 3

[0059] In this embodiment, the method of the present invention is used to carry out on-site construction of Yuan A well. Well Yuan A is an oil production well put into production in September 2014. Before casing damage, the oil production was 3.3t / d. In August 2018, casing damage was found, and the water cut after casing damage was 100%. Engineering logging found that the casing damage section was 3 meters (1156m-1159m), the perforation section is 1312-1316m, and the chemical plugging operation is carried out.

[0060] The plugging process is as follows:

[0061] 1. Using a conventional packer to test the casing damage section of the casing damage well, the water absorption is 330L / min under the pressure of 10MPa;

[0062] 2. Lower the light oil pipe to 956 meters in the casing of the casing damaged well, and close the casing gate;

[0063] 3. Prepare and inject 300L of 0.35% guar gum solution, let it sink naturally for 20 minutes to the bottom of the well, and plug the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com