Pressure relief electric explosion valve

A technology of electric explosion and valve, applied in the direction of valve details, safety valves, engine components, etc., can solve the problems of large volume and complex structure of electric explosion valve, and achieve the effect of simple structure, small volume and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In conjunction with the accompanying drawings of the description, this invention is carefully interpreted.

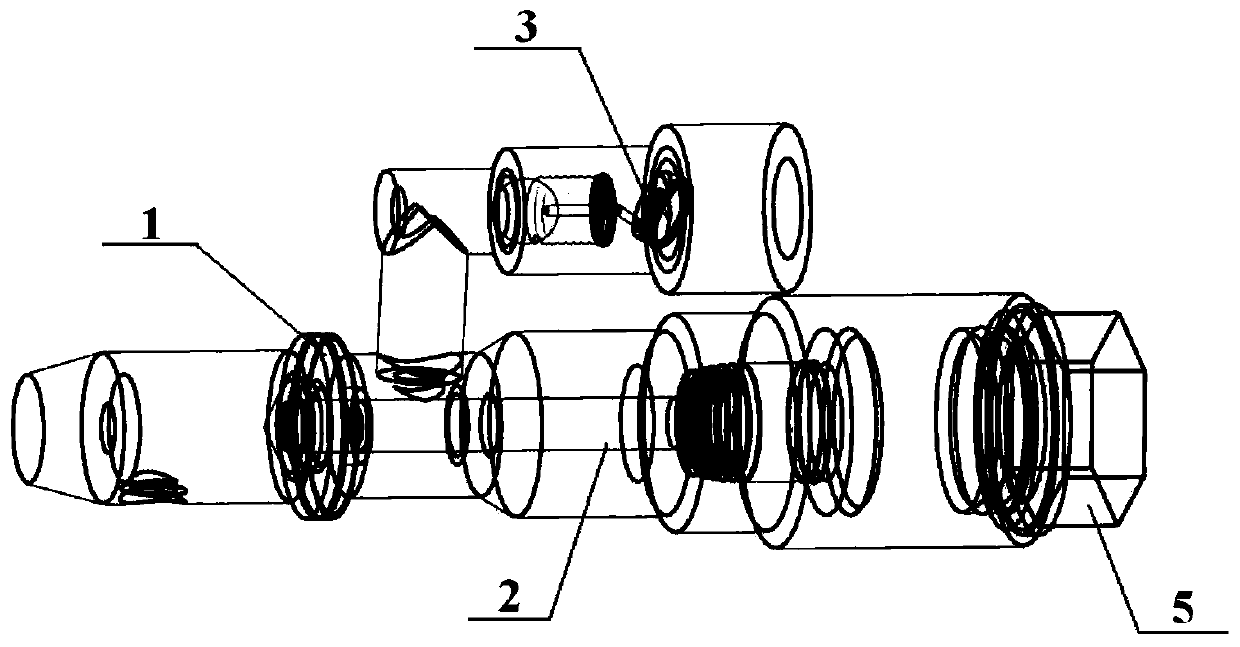

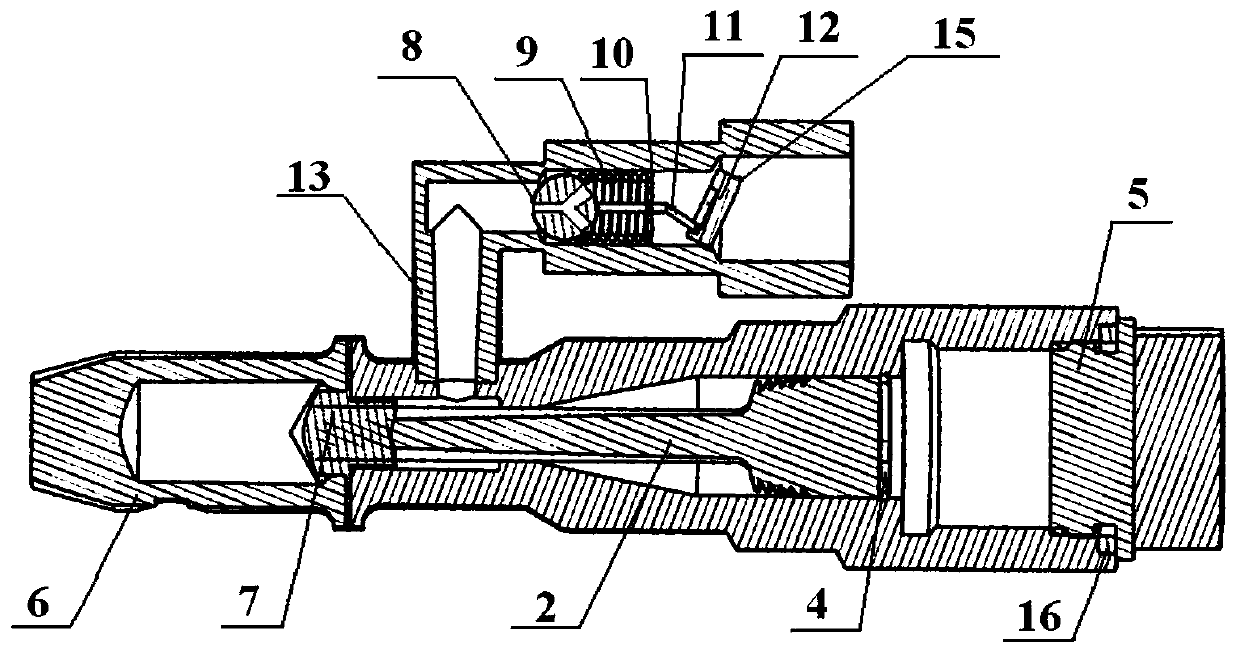

[0027] Such as figure 1 , figure 2 As shown, a decompression electric explosion valve includes: a housing assembly 1 , a piston 2 , a decompression pipeline device 3 , a snap ring 4 , and an igniter 5 . The piston 2 is placed inside the housing assembly 1 and fixed with a snap ring 4 , and the decompression pipeline device 3 is installed at the outlet of the housing assembly 1 . The igniter 5 is installed at the tail end of the shell assembly 1 and sealed by the gasket 16. The igniter ignites and pushes the piston, cuts off the diaphragm, opens the electric explosion valve, and makes the fluid enter the decompression pipeline device.

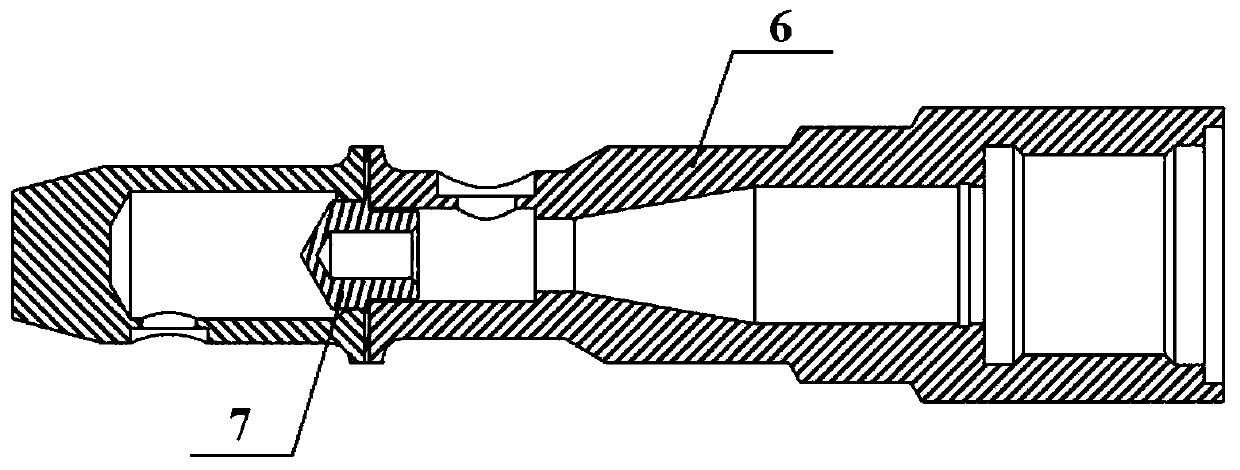

[0028] Such as image 3 The shown housing assembly 1 includes: a housing 6 and a diaphragm 7 , and the diaphragm 7 is fixed at the front end of the housing 6 . The front end of the piston 2 is pressed against the diaphragm 7 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com