Breaking machine for deodorization compound biosphere production

A technology of crusher and bio-ball, which is applied in the direction of grain processing, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as secondary pollution, incomplete crushing, and influence on deodorization effect, and achieve the goal of ensuring crushing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

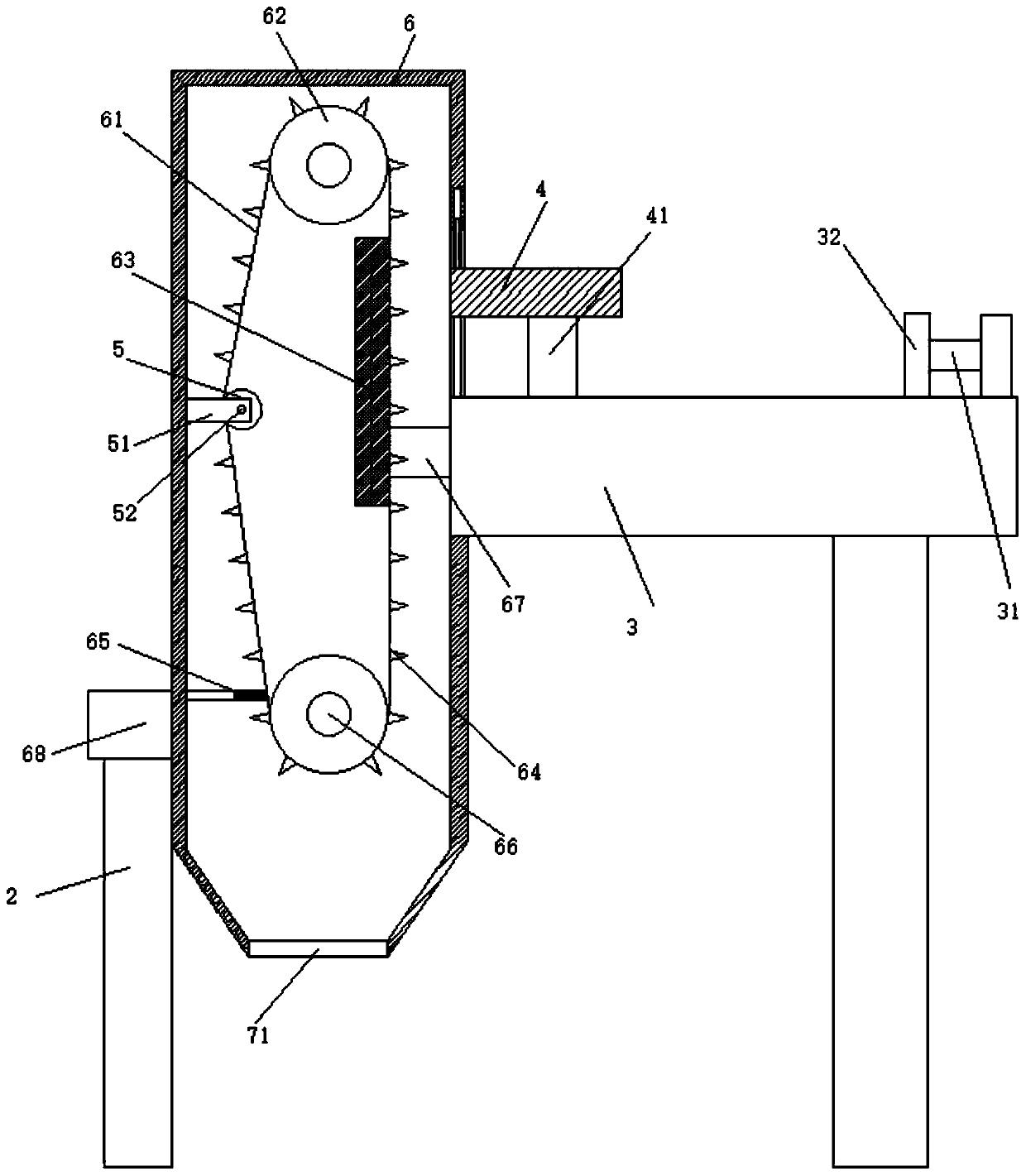

[0049] see Figure 3-6 , a crusher for deodorizing composite biosphere production, comprising a crusher shell 6 and a feed table 3, one side of the crusher shell 6 is provided with a feed port 69, and the crusher positioned at the feed port 69 The housing 6 is provided with a fixedly connected feeding table 3, and the crusher housing 6 located at the feed inlet 69 is provided with a vertically distributed conveyor belt 61, and the conveyor belt 61 is provided with a plurality of crushing teeth 64 , and the conveyor belt 61 is provided with a top plate 63, the two ends of the top plate 63 are provided with symmetrically distributed fixed rods 67, and the extended ends of the fixed rods 67 are fixedly connected with the inner wall of the crusher shell 6 at the feed inlet 69, and are located at the feed inlet. A feed plate 4 is provided on the feed table 3 at the feed port 69 , and a discharge port 7 is provided at the bottom of the crusher shell 6 .

[0050] Due to the very goo...

Embodiment 2

[0064] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

[0065] see Figure 6 , the crusher is used in the production and processing flow of bio-balls;

[0066] Further, the production of the biosphere comprises the following steps:

[0067] A method for preparing bioballs by adopting polypropylene and sawdust, comprising the following steps:

[0068] (1) Process wood chips into wood chip masterbatch;

[0069] (2) Send the main material PP (polypropylene), sawdust masterbatch, foaming agent, and lubricant into the autoclave at a ratio of 0.75:0.12:0.06:0.07 for mixing and stirring to obtain material A;

[0070] (3) Feed material A into the extruder for extrusion drawing and pelletizing, with a particle size of 1-5mm;

[0071] (4) heating and pressurizing the particles in a foaming device to obtain disposable foamed particles;

[0072] (5) pre-compressing the primary foamed particles to implement secondary foaming, and drying the secondar...

Embodiment 3

[0080] The same as embodiment 2 is not repeated, and the difference with embodiment 1 is:

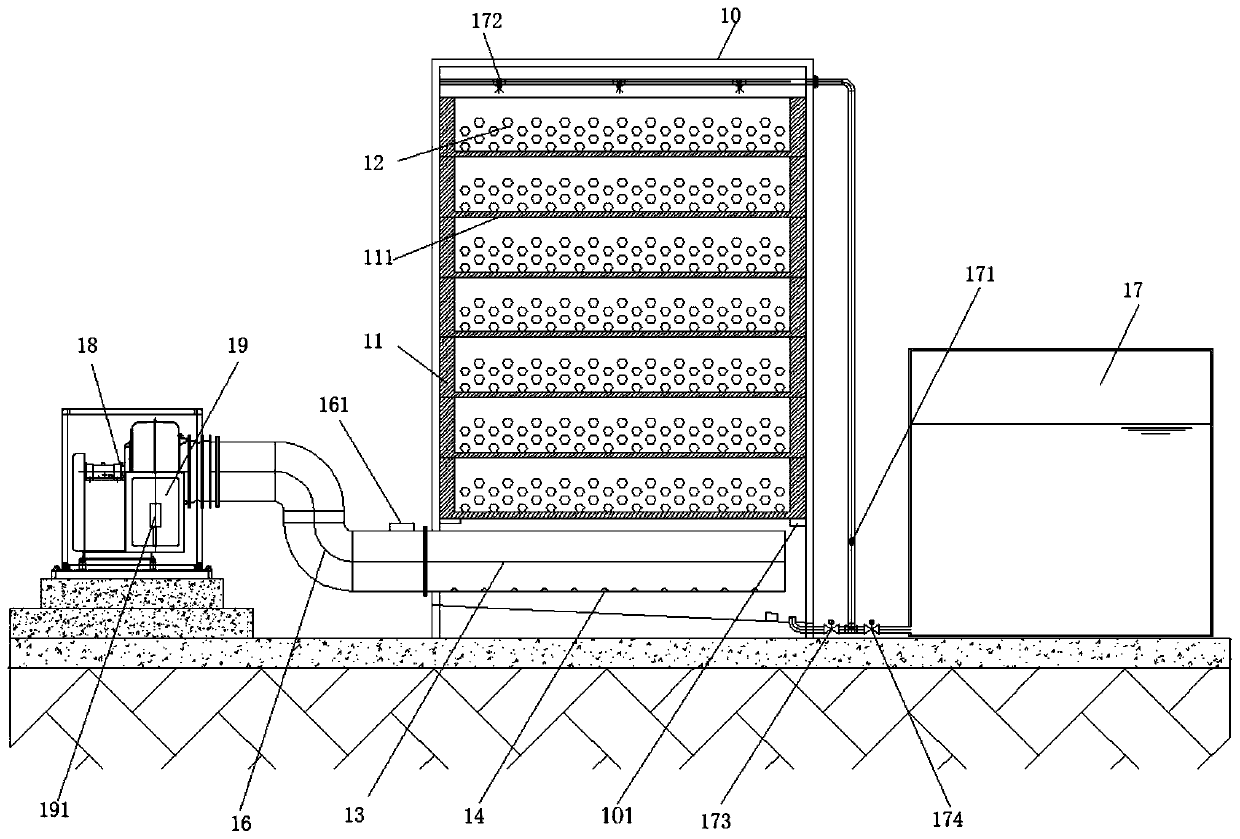

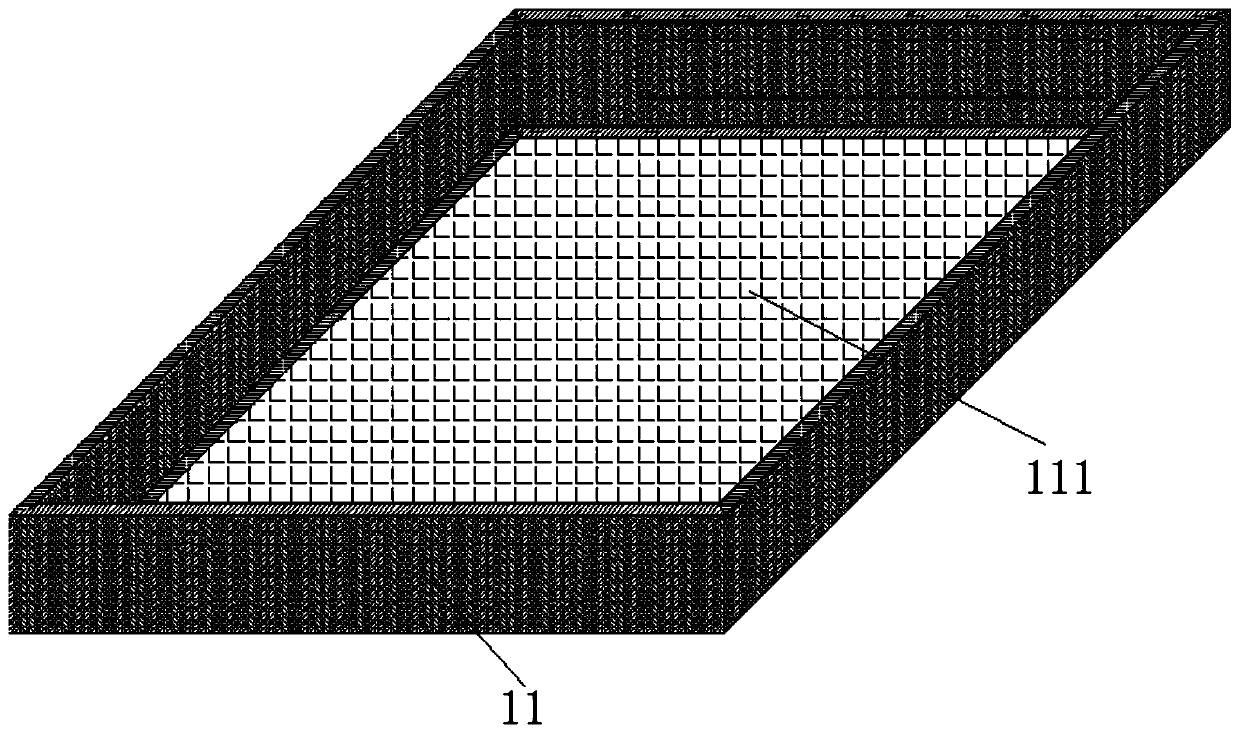

[0081] see Figure 1-2 , the bio-ball is used in the bio-ball deodorization device

[0082] Further, the bio-ball deodorization device includes a deodorization box, including a deodorization box 10, an air intake pipe 17 is provided on one side of the bottom of the deodorization box 10, and a A plurality of deodorizing beds 11 stacked one after another, the deodorizing beds 11 are square frames, and the bottom of the deodorizing beds 11 are all provided with fixedly connected partition nets 111, located in the deodorizing beds 11 at the top of the partition nets 111 A plurality of biospheres 12 for cultivating domesticated microorganisms are stored.

[0083] The design of the multi-layer partition net can not only make the distribution of bio-balls more uniform in the deodorization box, but also continuously turn the bio-balls through the air intake, showing a boiling shape, increasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com