Laser equipment for splitting battery pieces

A technology of laser equipment and batteries, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex structure of mechanical breaking pieces, scrapping of batteries in batches, cumbersome use steps, etc., and achieve good economic use value, Shorten splitting time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

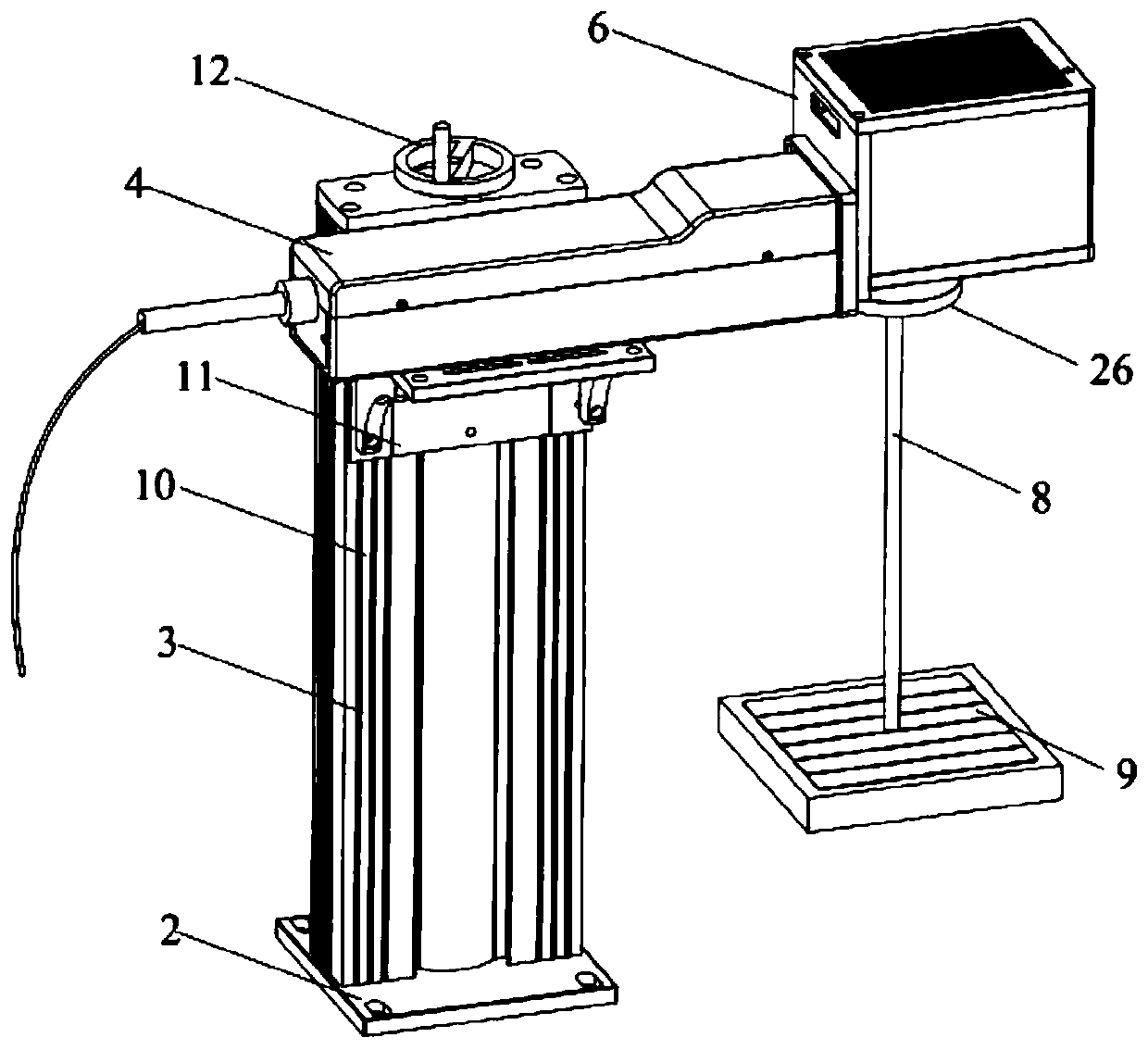

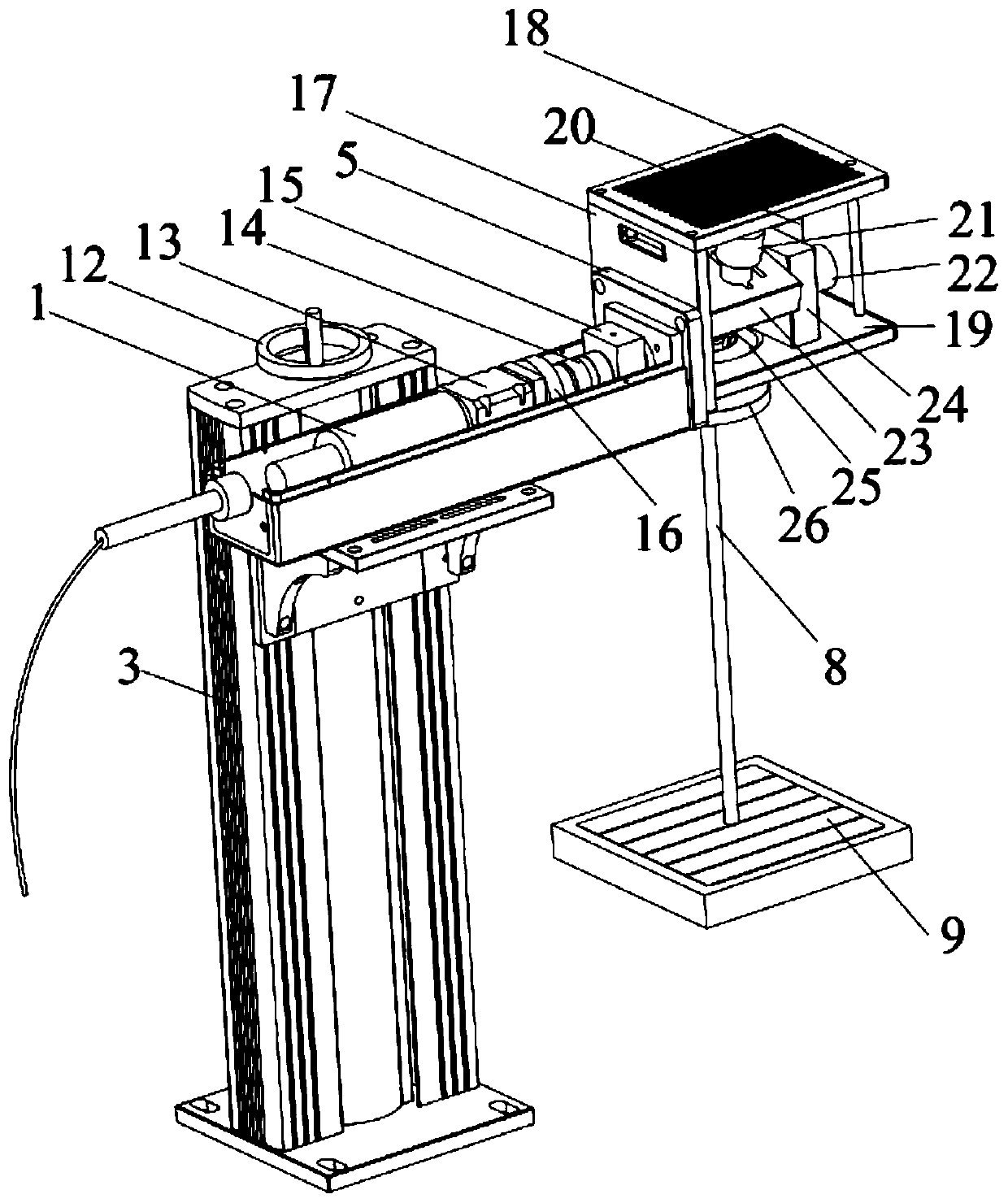

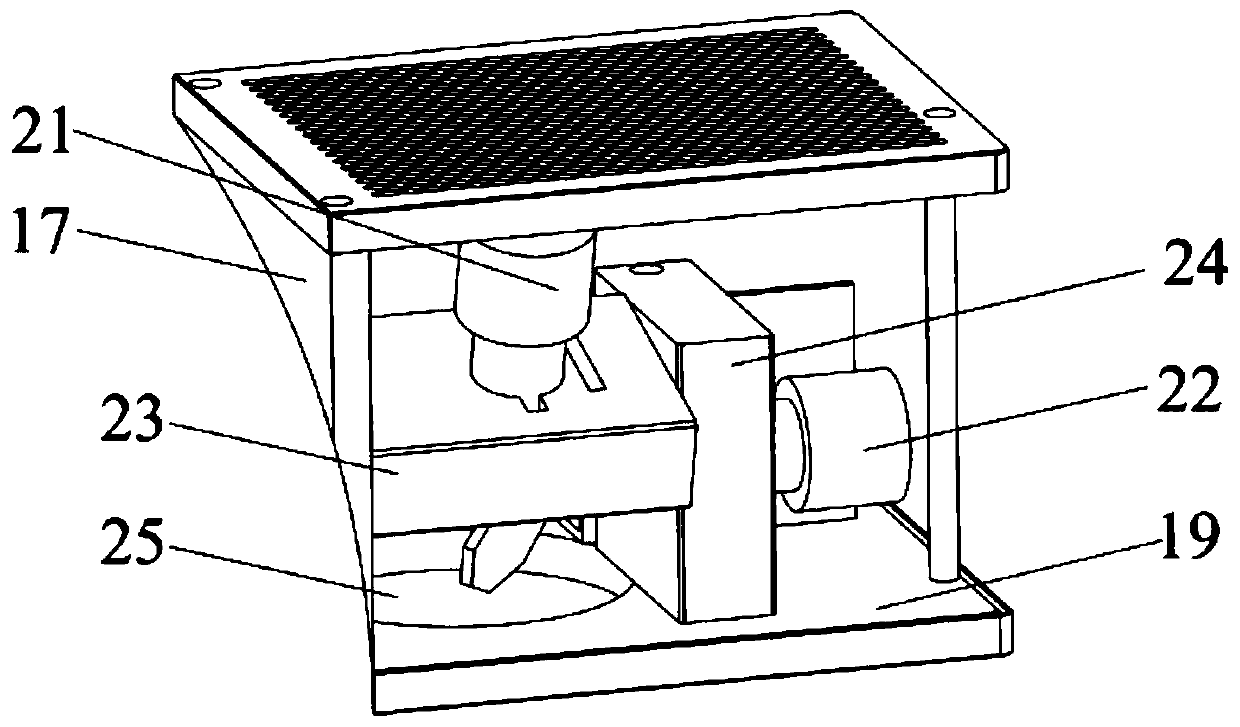

[0017] Such as Figure 1 ~ Figure 4 As shown, the present invention is a laser device for splitting cells, which includes a laser 1, a base 2, a lifting column 3 is installed on the base 2, a laser cover 4 is installed sliding up and down on the lifting column 3, and the laser 1 is installed in the laser cover 4, the laser cover 4 along the emission direction of the laser beam 8 of the laser 1 is equipped with a speed-expanding mirror assembly connected to the laser 1. connection, the adapter plate 5 and the galvanometer cover 6 are provided with a light outlet 7, and the light outlet 7 is horizontally aligned with the laser beam 8 output port of the laser 1, and the galvanometer cover 6 is equipped with a galvanometer assembly to direct the laser beam 8 is deflected onto the battery sheet 9 placed below the galvanometer cover 6 .

[0018] The lifting column 3 is provided with a slide rail 10, the laser cover 4 is installed on the slide rail 10 through the sliding seat 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com