A latent halogen-free flame-retardant epoxy resin curing agent, epoxy resin prepreg and carbon fiber composite material

A technology of epoxy resin curing and epoxy resin, which is applied in the fields of epoxy resin curing agent, epoxy resin prepreg and carbon fiber composite materials, and can solve the problems of poor flame retardancy, short operation time of epoxy resin and its prepreg, etc. problems, to achieve the effect of improving the halogen-free flame retardancy, increasing the activation energy of the curing reaction, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

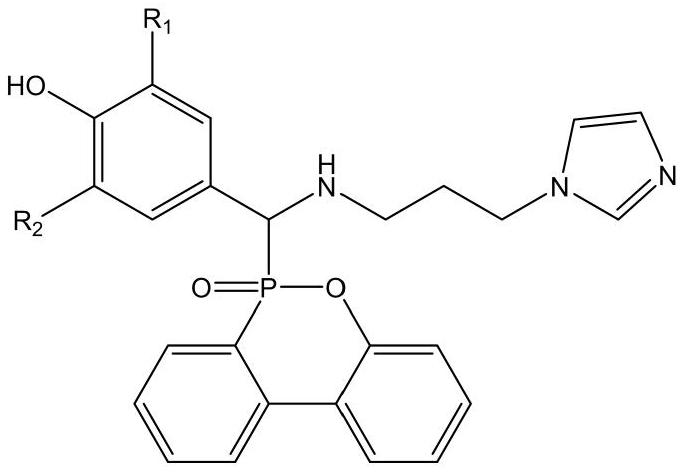

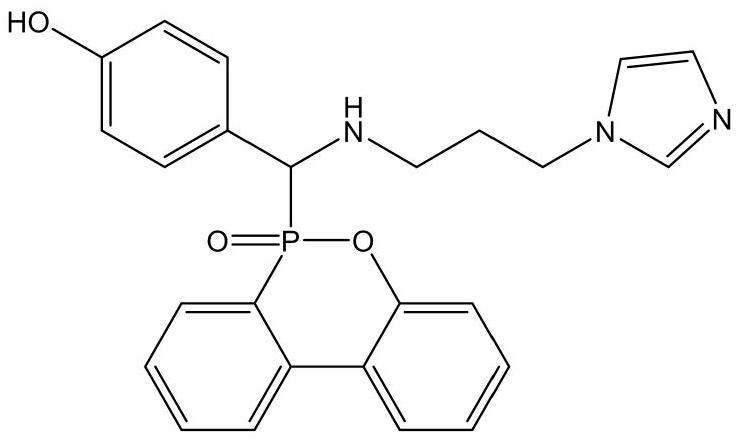

[0034] Experimental Example 1: Structural Characterization:

[0035] use 1 HNMR and element analysis characterize the structure of the latent halogen-free flame-retardant epoxy resin curing agent in the following examples.

[0036] Preparation of latent halogen-free flame retardant epoxy resin curing agent:

[0037] At room temperature and under the protection of nitrogen, add 1L of N-(3-aminopropyl)-imidazole and absolute ethanol mixture with a concentration of 0.1M in a container equipped with a reflux condensing device and a magnetic stirrer, stir well and then heat up to 60 ℃, then slowly add 0.5L of a mixture of p-hydroxybenzaldehyde and absolute ethanol with a concentration of 0.2M, and continue stirring for 4 hours;

[0038] After cooling to room temperature, 0.5 L of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and absolute ethanol were slowly added dropwise to the resulting mixture. The mixture was reacted at room temperature and under stirring conditi...

experiment example 3

[0063] Experimental Example 3: Glass transition temperature test:

[0064] Use a dynamic mechanical analyzer to test the glass transition temperature of the carbon fiber composite material in the following examples. The test adopts a single cantilever beam mode, the heating rate is 3°C / min, and the peak temperature of the loss tangent value-temperature curve is taken as the glass transition temperature.

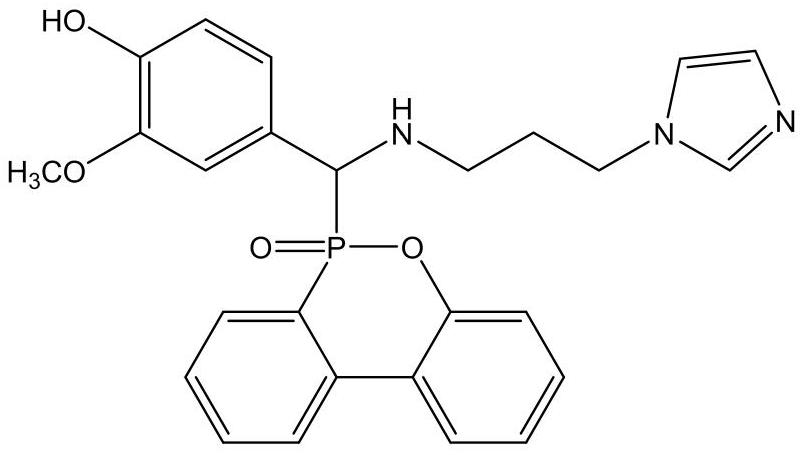

[0065] Preparation of latent halogen-free flame retardant epoxy resin curing agent:

[0066] At room temperature and under the protection of nitrogen, add 1L of N-(3-aminopropyl)-imidazole and absolute ethanol mixture with a concentration of 0.2M in a container equipped with a reflux condensing device and a magnetic stirrer, stir well and then heat up to 60 ℃, then slowly add 1L of a 0.2M concentrated mixture of syringaldehyde and absolute ethanol, and continue stirring for 6 hours. After cooling to room temperature, slowly dropwise add 1L of 9,10-dihydro-9-oxa-10-phosphaph...

experiment example 4

[0077] Experimental example 4: Tensile performance test:

[0078] Using a universal mechanical testing machine, according to the ASTM D3039 test standard, the tensile properties of the carbon fiber composite materials in the following examples were tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com