Method for preparing polyacetylene electrospun nanofibers

A nanofiber and polyacetylene electrospinning technology, applied in spinning solution preparation, fiber treatment, electrospinning, etc., can solve the problems of poor controllability of fiber material structure and shape, cumbersome preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

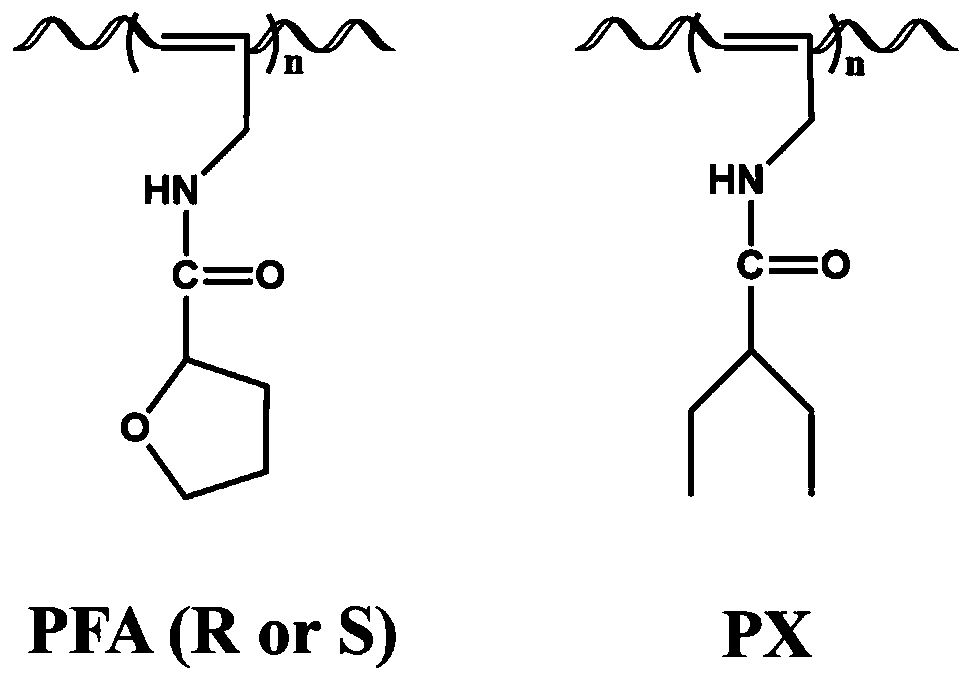

[0037] The embodiment of the present invention provides a method for preparing chiral polyyne nanofibers by electrospinning. The specific operation steps include: dissolving R(S)-PFA in an appropriate amount of DMF solvent, stirring magnetically for a period of time until dissolved, A spinning solution with a polyyne content of 1 g / mL was obtained.

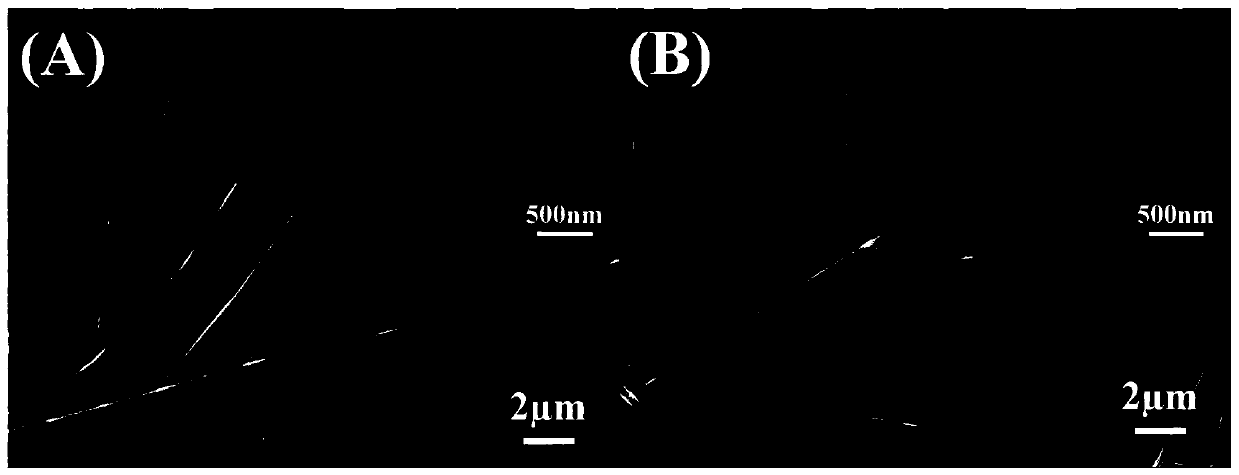

[0038] Add the polymer spinning solution obtained above into the syringe of the electrospinning equipment, control the electrospinning parameters such as voltage and propulsion speed, and continue to electrospin stably for a period of time to obtain chiral polyyne nanofibers with uniform diameter and continuous (EF-R(S)-PFA). Electrospinning operating parameters: electrospinning positive voltage 6kV, electrospraying negative voltage -2kV, the distance from the spinneret to the receiving plate is 16cm, the temperature is 30°C, the humidity is 35%, and the propulsion speed is 0.004mL / min.

[0039] Take an appropriate amount of the ...

Embodiment 2

[0041] The embodiment of the present invention provides a method for preparing continuous polyyne nanofibers by electrospinning. The specific operation steps include: dissolving the helical substituted polyyne PX in an appropriate amount of mixed solvent (OX:CHCl 3 =4:1, volume ratio), magnetically stirred for a period of time until dissolved to obtain a spinning solution with a polyyne content of 320 mg / mL.

[0042] Add the polymer spinning solution obtained above into the syringe of the electrospinning equipment, control the electrospinning parameters such as voltage and propulsion speed, and continue to electrospin stably for a period of time to obtain continuous polyyne nanofibers (EF-PX) . Electrospinning operating parameters: electrospinning positive voltage 6kV, electrospraying negative voltage -2kV, the distance from the spinneret to the receiving plate is 16cm, the temperature is 30°C, the humidity is 35%, and the propulsion speed is 0.004mL / min.

Embodiment 3

[0044] The embodiment of the present invention provides a method for preparing chiral composite nanofibers with excellent mechanical properties by electrospinning. Dissolve PFA in an appropriate amount of DMF solvent, stir it for a period of time until it is completely dissolved, and obtain a spinning solution of composite fibers containing chiral helical substituted polyyne.

[0045] Add the polymer spinning solution obtained above into the syringe of the electrospinning equipment, control the electrospinning parameters such as voltage and propulsion speed, and continue to electrospin stably for a period of time to obtain uniform and continuous chiral composite nanofibers ( EF-PAN+R(S)-PFA). Electrospinning operating parameters: electrospinning positive voltage 6kV, electrospraying negative voltage -2kV, the distance from the spinneret to the receiving plate is 16cm, the temperature is 30°C, the humidity is 35%, and the propulsion speed is 0.004mL / min.

[0046] The composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com