Optical modulator

An optical modulator and optical transmission technology, used in instruments, optics, nonlinear optics, etc., can solve the problems of large size, low efficiency, and high energy consumption of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

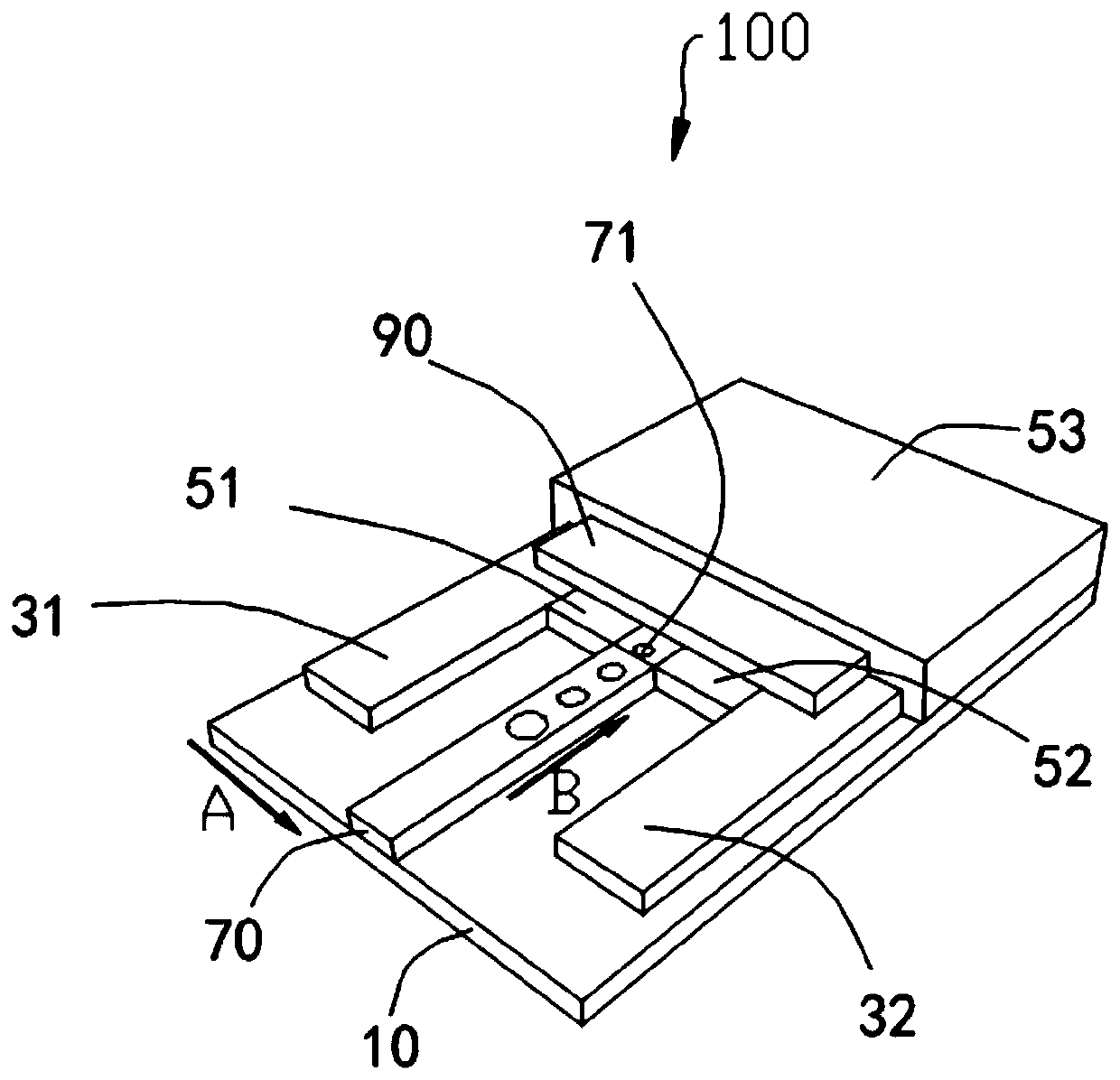

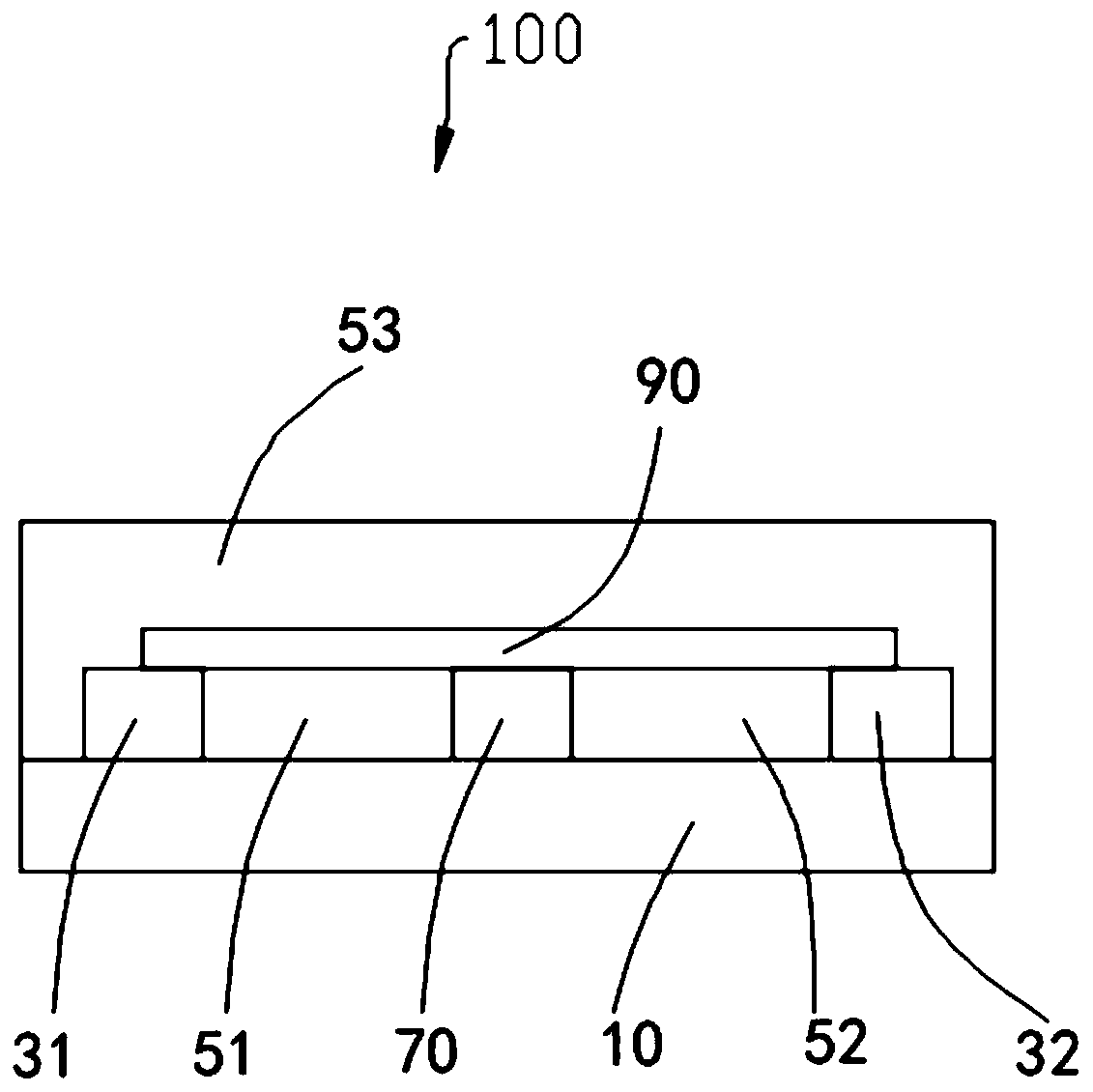

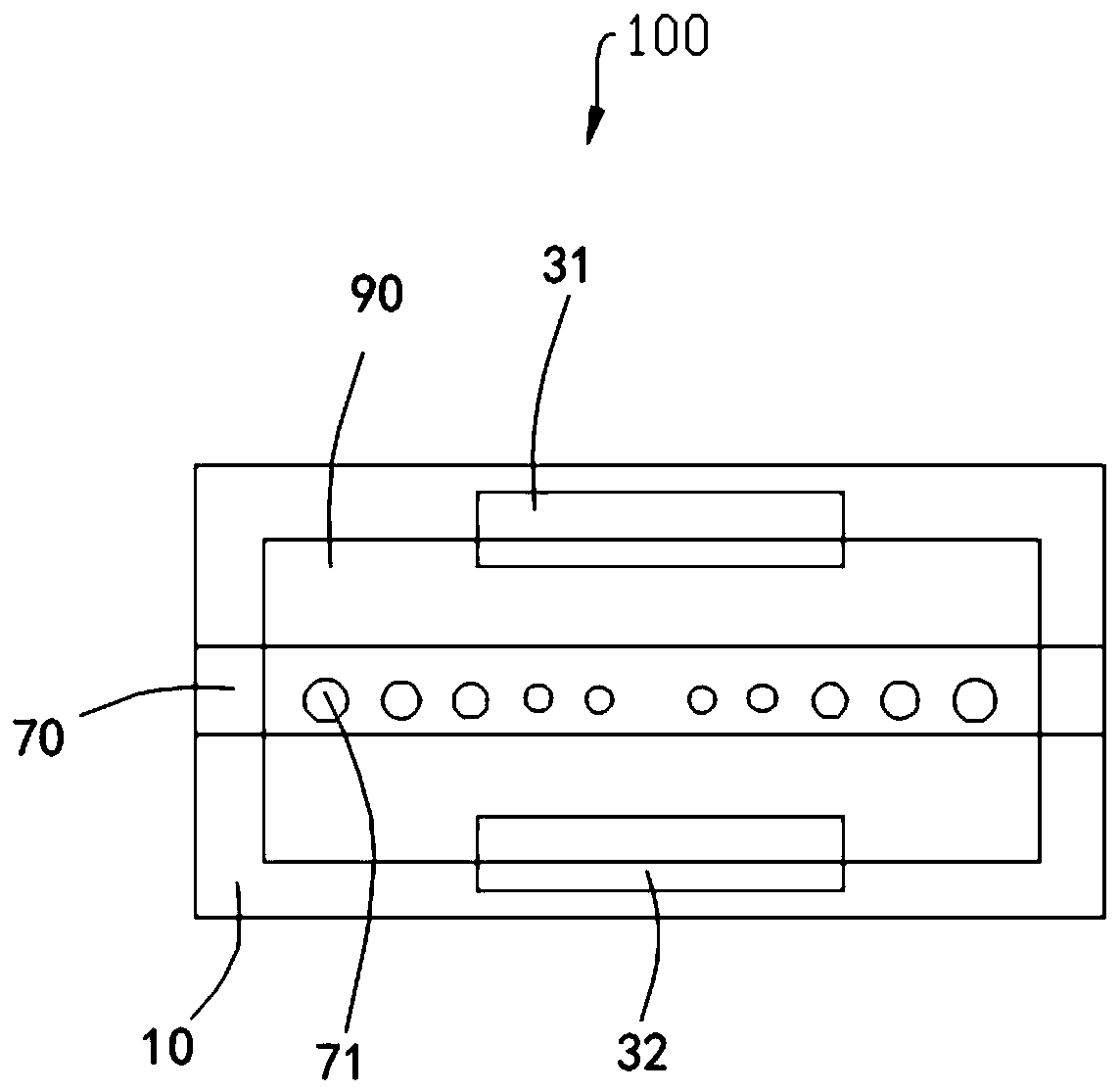

[0075] The optical modulator 100 based on black phosphorous in this embodiment includes a substrate 10, a first electrode 31, a second electrode 32, a first protection member 51, a second protection member 52, a waveguide 70, a thermal layer 90 and a third protection member. piece 53. The first electrode 31, the first protection member 51, the waveguide 70, the second protection member 53, and the second electrode 31 are along the first direction (such as figure 1 Arrow A) are arranged in sequence and arranged on the substrate 10. The waveguide 70 is provided with along the light transmission direction (such as figure 1 Arrow B) arranged through holes 71. The first direction is perpendicular to the light transmission direction. The thermal layer 90 at least partially covers the first electrode 31 and the second electrode 32, and completely covers the through hole 71; the third protection member 53 is formed on the thermal layer 90, and completely covers the first electrode ...

Embodiment 2

[0079] The optical modulator 100 based on black phosphorous in this embodiment includes a substrate 10, a first electrode 31, a second electrode 32, a first protection member 51, a second protection member 52, a waveguide 70, a thermal layer 90 and a third protection member. piece 53. The first electrode 31, the first protection member 51, the waveguide 70, the second protection member 53, and the second electrode 31 are along the first direction (such as figure 1 Arrow A) are arranged in sequence and arranged on the substrate 10. The waveguide 70 is provided with along the light transmission direction (such as figure 1 Arrow B) arranged through holes 71. The first direction is perpendicular to the light transmission direction. The thermal layer 90 at least partially covers the first electrode 31 and the second electrode 32, and completely covers the through hole 71; the third protection member 53 is formed on the thermal layer 90, and completely covers the first electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com