Novel type mode-locked laser

A mode-locked laser, a new technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of demanding technical conditions, high maintenance costs, high costs, etc., to achieve low cost, low manufacturing cost, high performance Reliable and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

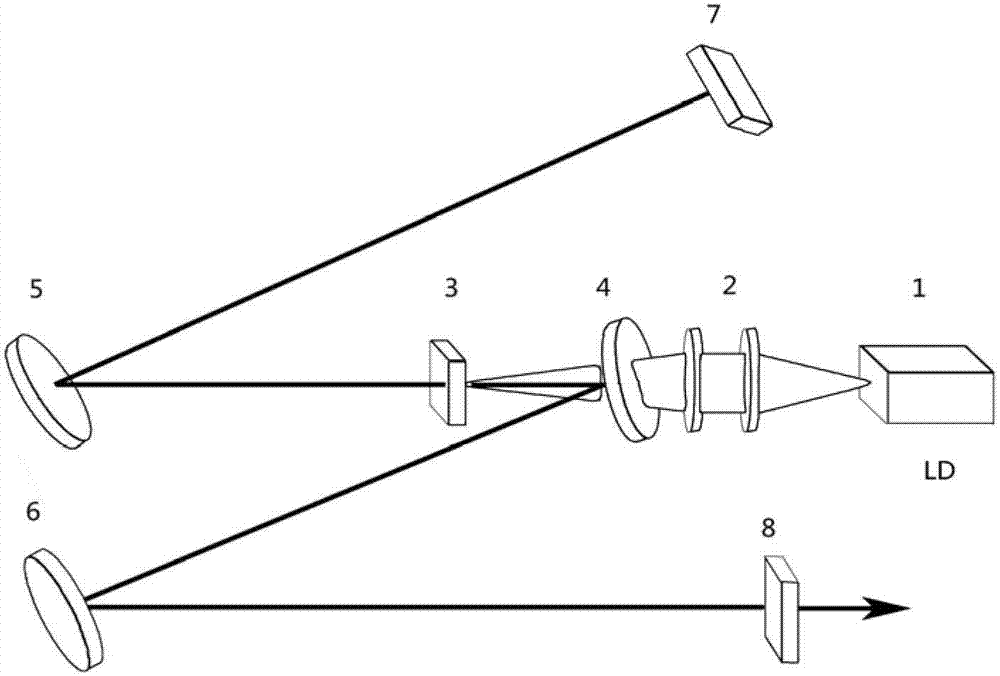

[0024] A new type of mode-locked laser, such as figure 1 As shown, it includes diode pumping source 1, coupling system 2, laser gain medium 3 and laser resonator, diode pumping source 1, coupling system 2 and laser resonator are arranged in order to form an optical path, and laser gain medium 3 is located in the laser resonator , which is characterized in that the laser resonator includes an input cavity mirror 4, two reflectors A5, B6, two semiconductor saturable absorption mirrors (SESAM) A7, B8, and the back of the input cavity mirror 4 is divided into two optical paths, one of which is in the optical path The sequence is laser gain medium 3, mirror A5, and semiconductor saturable absorbing mirror (SESAM) A7, and the sequence in the other optical path is mirror B6, semiconductor saturable absorbing mirror (SESAM) B8, and semiconductor saturable absorbing mirror (SESAM) A7 It is coated with a reflective film that is highly reflective to the resonant light in the cavity, and...

Embodiment 2

[0032] A new mode-locked laser, including a diode pumping source 1, a coupling system 2, a laser gain medium 3 and a laser resonator. The diode pumping source 1, coupling system 2 and the laser resonator are sequentially arranged in an optical path, and the laser gain medium 3 is located in In the laser resonant cavity, it is characterized in that the laser resonant cavity includes an input cavity mirror 4, two mirrors A5, B6, two semiconductor saturable absorber mirrors (SESAM) A7, B8, and the rear of the input cavity mirror 4 is divided into two optical paths, The sequence in one optical path is laser gain medium 3, reflector A5 and semiconductor saturable absorber mirror (SESAM) A7, and the sequence in the other optical path is reflector B6 and semiconductor saturable absorber mirror (SESAM) B8, semiconductor saturable absorber mirror (SESAM) A7 is coated with a reflective film that is highly reflective to the resonant light in the cavity, and the semiconductor saturable abs...

Embodiment 3

[0040] Same as Example 1, except that the laser gain medium 3 is Yb:GAGG crystal doped at 10 at%.

[0041] The resonant light, that is, the wavelength of the laser is 1030 nanometers; the semiconductor saturable absorption mirror (SESAM) A is coated with a reflective film that is highly reflective to the resonant light in the cavity with a wavelength of 1030 nanometers, and its reflectivity is greater than 99%; the semiconductor saturable absorption mirror (SESAM) B is coated with a film that partially reflects and partially transmits the resonant light in the cavity with a wavelength of 1030 nm, and its transmittance is 3.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com