Method for preparing SOI by reducing injection damage

A technology of implantation damage and ion implantation, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of ion residue, inability to guarantee SOI yield, poor SOI surface particles and roughness, etc., and achieve great economic value and social values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Various example embodiments will now be described more fully with reference to the accompanying drawings, in which some example embodiments are shown.

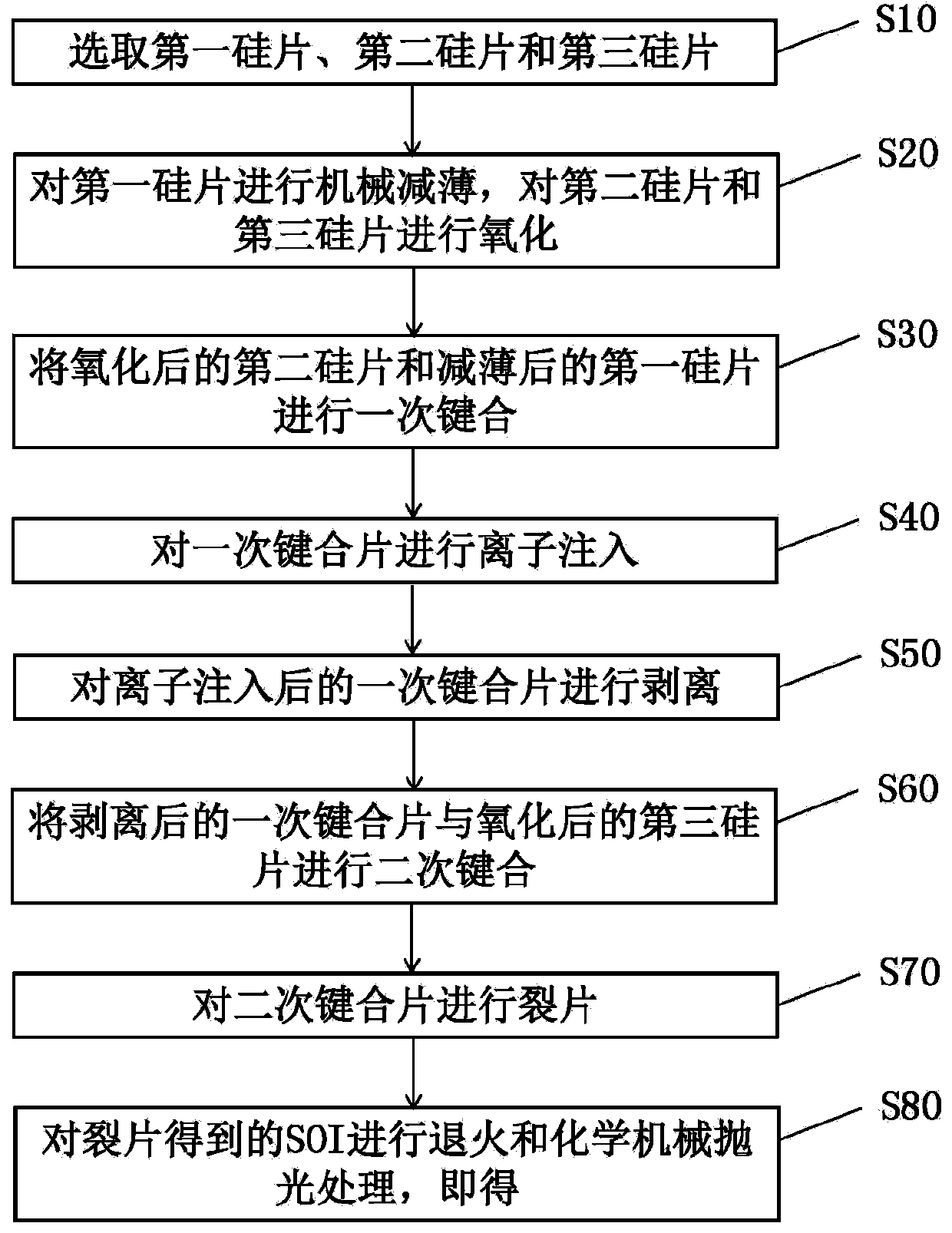

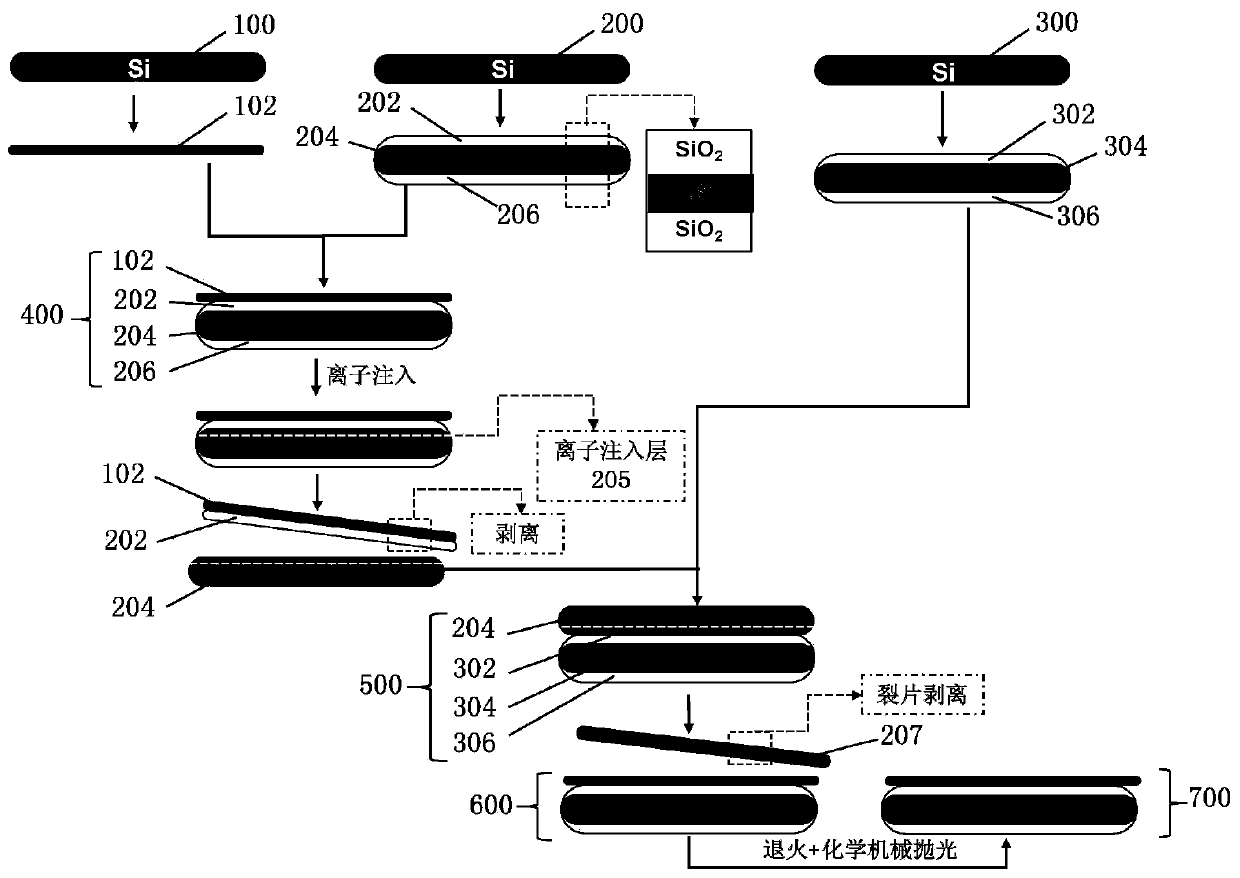

[0020] Refer below figure 1 and figure 2 A method for preparing SOI with reduced injection damage according to an embodiment of the present invention is described.

[0021] figure 1 It is a flowchart of a method for preparing SOI with reduced injection damage according to an embodiment of the present invention, figure 2 A schematic diagram of preparing SOI for reducing implant damage according to an embodiment of the present invention.

[0022] refer to figure 1 and figure 2 , in step S10, select three original silicon wafers, namely the first silicon wafer 100, the second silicon wafer 200 and the third silicon wafer 300.

[0023] As an example, the first silicon wafer 100 , the second silicon wafer 200 and the third silicon wafer 300 may be the same silicon wafer or different silicon wafers, which is not limi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com