Crystal pulling system and method including crucible and barrier

A technology of barriers and crucibles, applied in the field of single crystal pulling systems, can solve problems such as not being fully satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

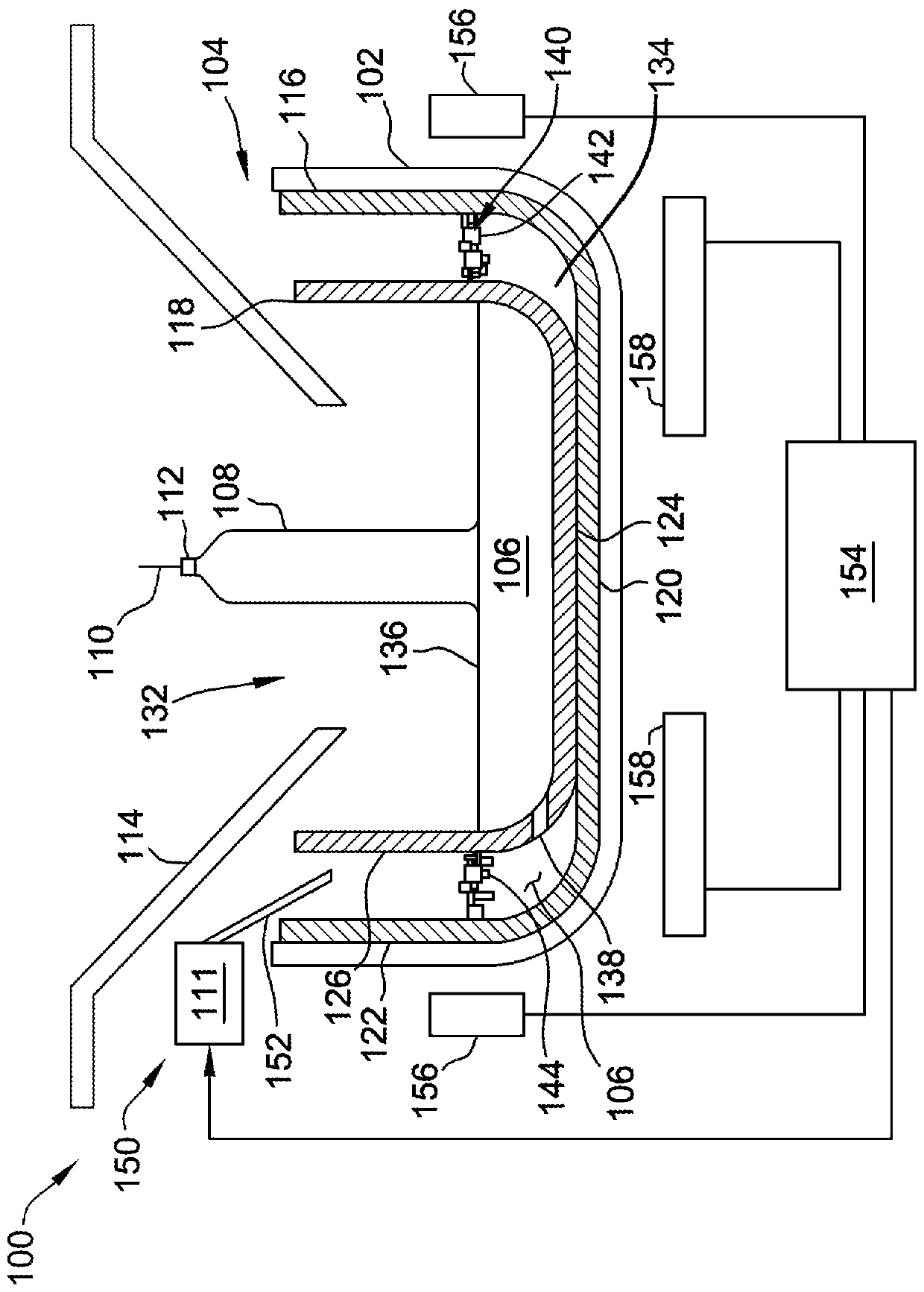

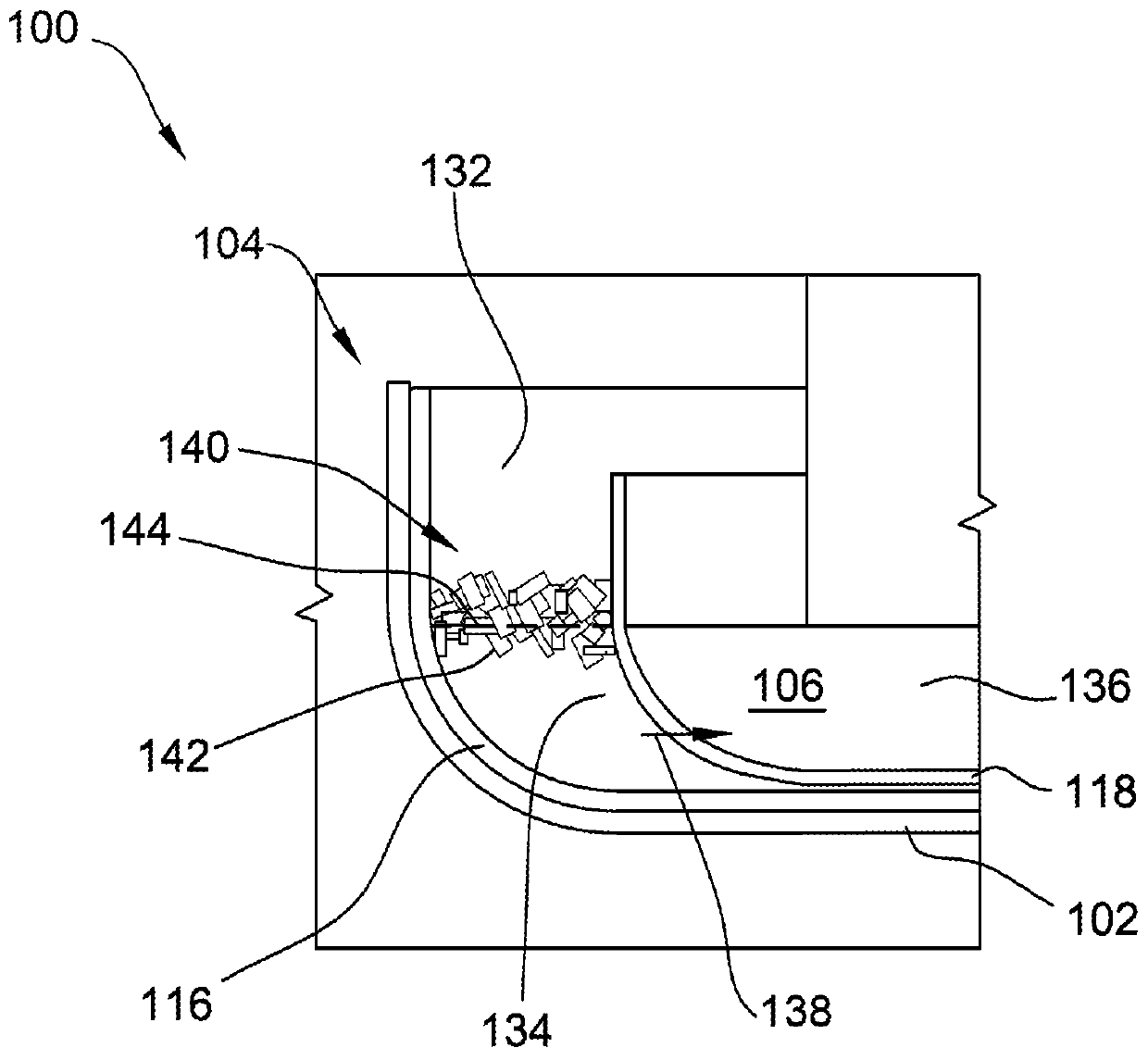

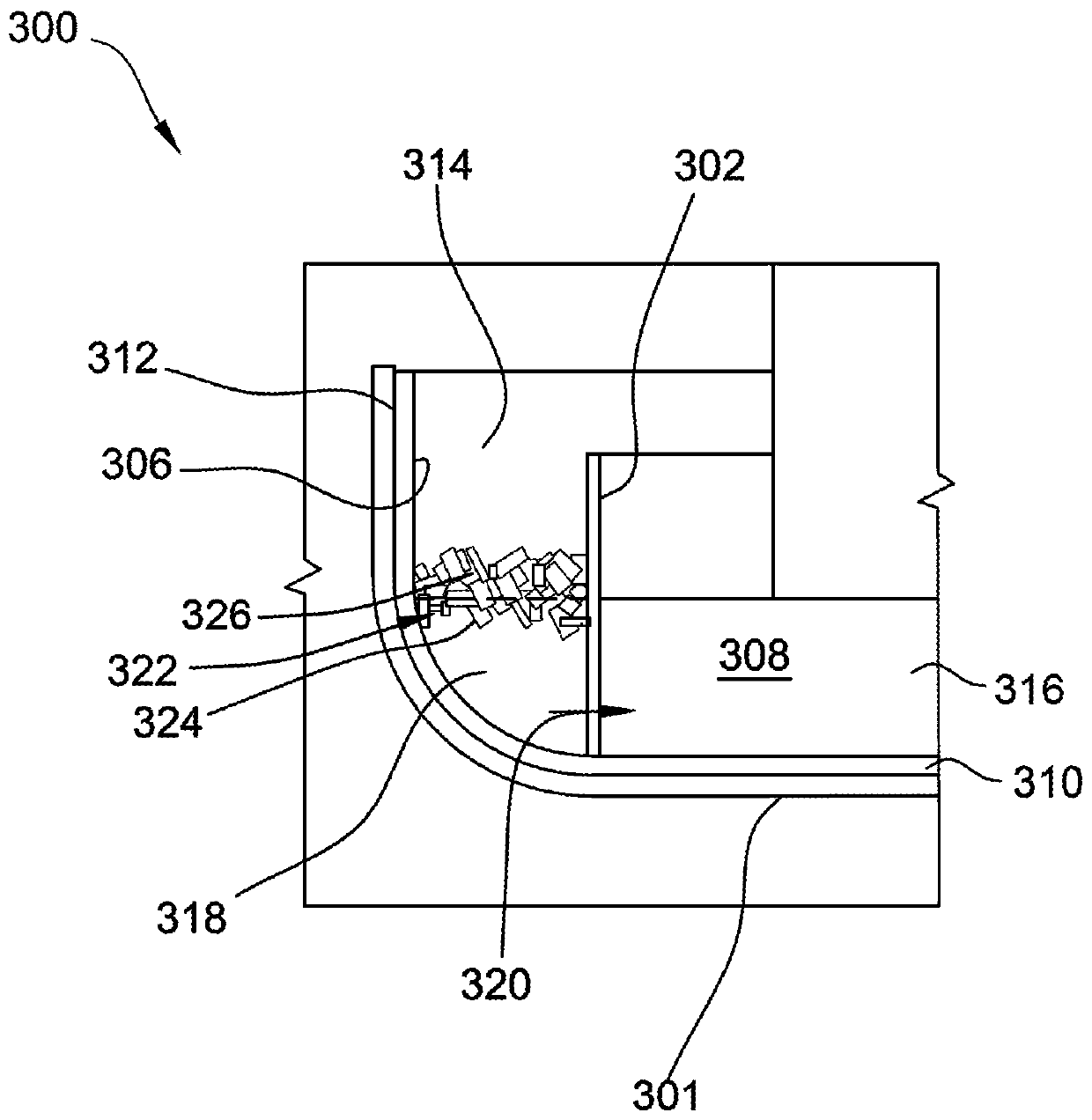

[0015] refer to figure 1 , which schematically illustrates a crystal pulling system, indicated generally at 100 . The crystal pulling system 100 may be used to produce crystal ingots by pulling.

[0016] The illustrated crystal pulling system 100 includes a susceptor 102 supporting a crucible assembly 104 containing a melt 106 of a semiconductor or solar grade material (eg, silicon). Melt 106 may be formed by heating solid feedstock 111 . During operation of system 100 , seed crystal 112 is lowered into melt 106 by crystal puller 110 and then slowly lifted from melt 106 . As the seed crystal 112 is slowly lifted from the melt 106 , the silicon atoms from the melt 106 align themselves with and adhere to the seed crystal 112 to form the ingot 108 . The illustrated system 100 also includes a thermal shield 114 to shield the ingot 108 from radiant heat from the melt 106 and to allow the ingot 108 to solidify.

[0017] Crucible assembly 104 includes a first crucible 116 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com