Extruded gluten and preparation method thereof

A gluten and drying technology, which is applied in food science, food preservation, and the function of food ingredients, etc., can solve the problems of stinking and spoilage bacteria in products, achieve low fat content, increase oil holding capacity, and extend shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

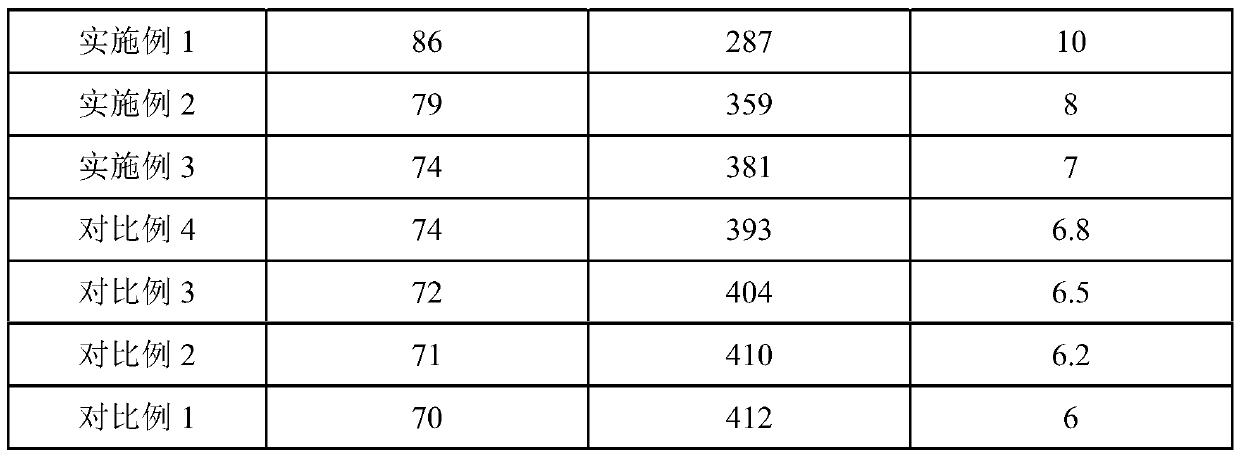

Embodiment 1

[0036] This embodiment provides an extruded gluten and a preparation method thereof.

[0037] The preparation method of extruded gluten is as follows:

[0038] (1) The apple pomace was treated with supercritical CO 2 Drying technology for drying; supercritical CO 2 The conditions of drying technology are: pressure: 35MPa; CO 2 Flow: 20L / h; Temperature: 55°C; Time: 70min;

[0039] (2) Grind the dried apple pomace with a superfine grinder at a speed of 6000rpm for 20s, then use a universal high-speed grinder at a speed of 25000r / min for 60s, and keep the part with a particle size of ≤0.125mm to obtain a powder substance;

[0040] (3) 2.5 parts of chitosan oligosaccharides and 20 parts of powder substances obtained in step (2) are added to 80 parts of medium-gluten wheat flour and mixed uniformly to obtain mixed powder;

[0041] (4) Mix 6 parts of table salt, 0.48 parts of monoglyceride and 30 parts of water evenly, and then add them to the mixed powder for powdering to obta...

Embodiment 2

[0045] This embodiment provides an extruded gluten and a preparation method thereof.

[0046] The difference between this embodiment and embodiment 1 is: in step (1), supercritical CO 2 The pressure of the drying treatment is 30MPa, and the temperature is 45°C. In step (3), in parts by weight, the amount of powdered substance is 18 parts, and the content of chitosan oligosaccharide is 2.0 parts.

[0047] Other each process step, process parameter and each raw material and consumption are all identical with embodiment 1.

Embodiment 3

[0049] This embodiment provides an extruded gluten and a preparation method thereof.

[0050] The difference between this embodiment and embodiment 1 is: in step (1), supercritical CO 2 The pressure of drying treatment is 25MPa, CO 2 The flow rate is 15L / h, the temperature is 40°C, and the time is 50min. In step (3), in parts by weight, the content of the powder substance is 14 parts, and the content of chitosan oligosaccharide is 1.0 parts.

[0051] Other each process step, process parameter and each raw material and consumption are all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com