Drilling equipment for industrial machinery production

A technology of drilling equipment and industrial machinery, applied in the field of drilling equipment for industrial machinery production, can solve problems such as poor dust suction effect, debris splashing and polluting the environment, and achieve reduced vibration, avoid debris splashing, and good shock absorption effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

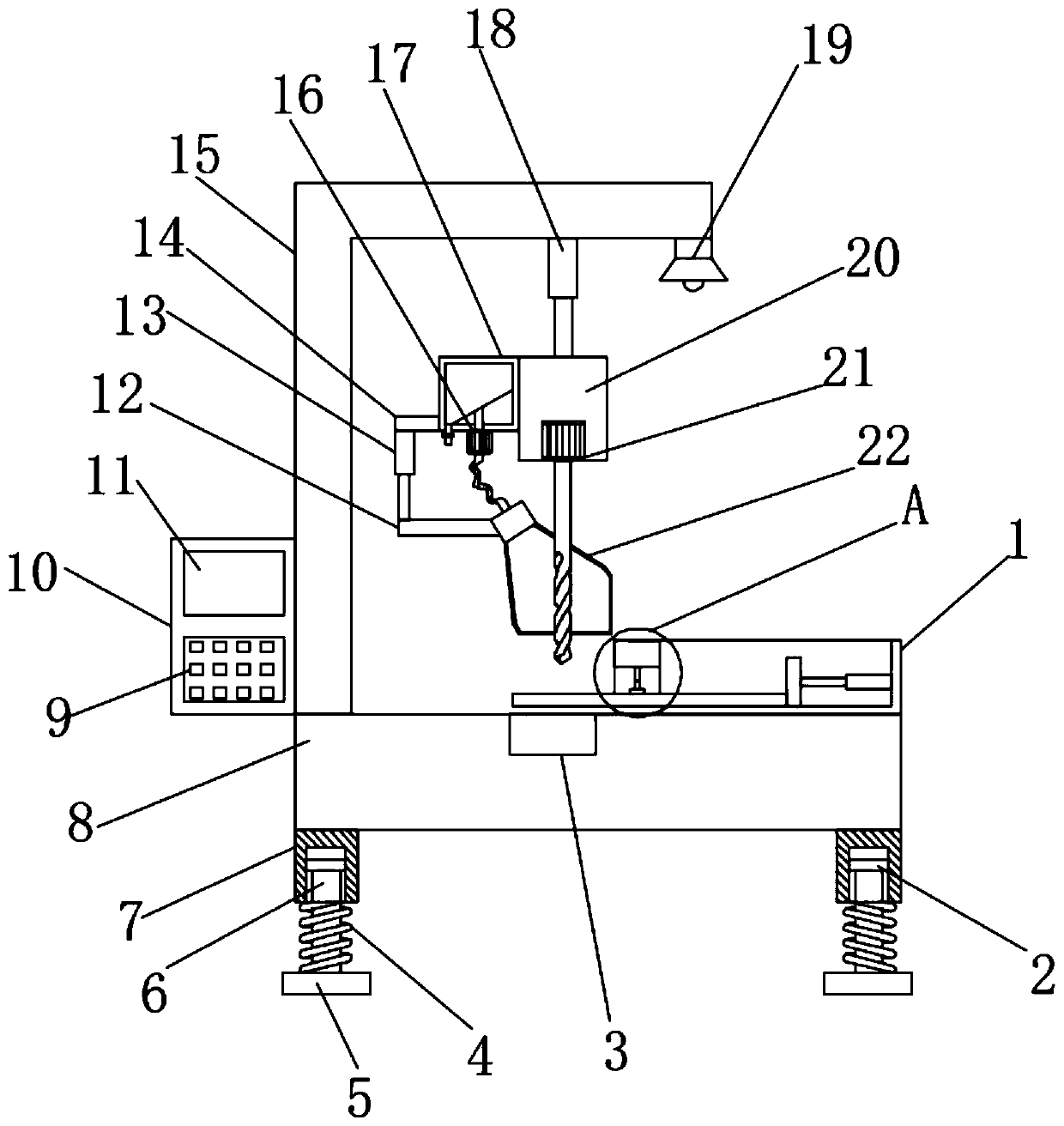

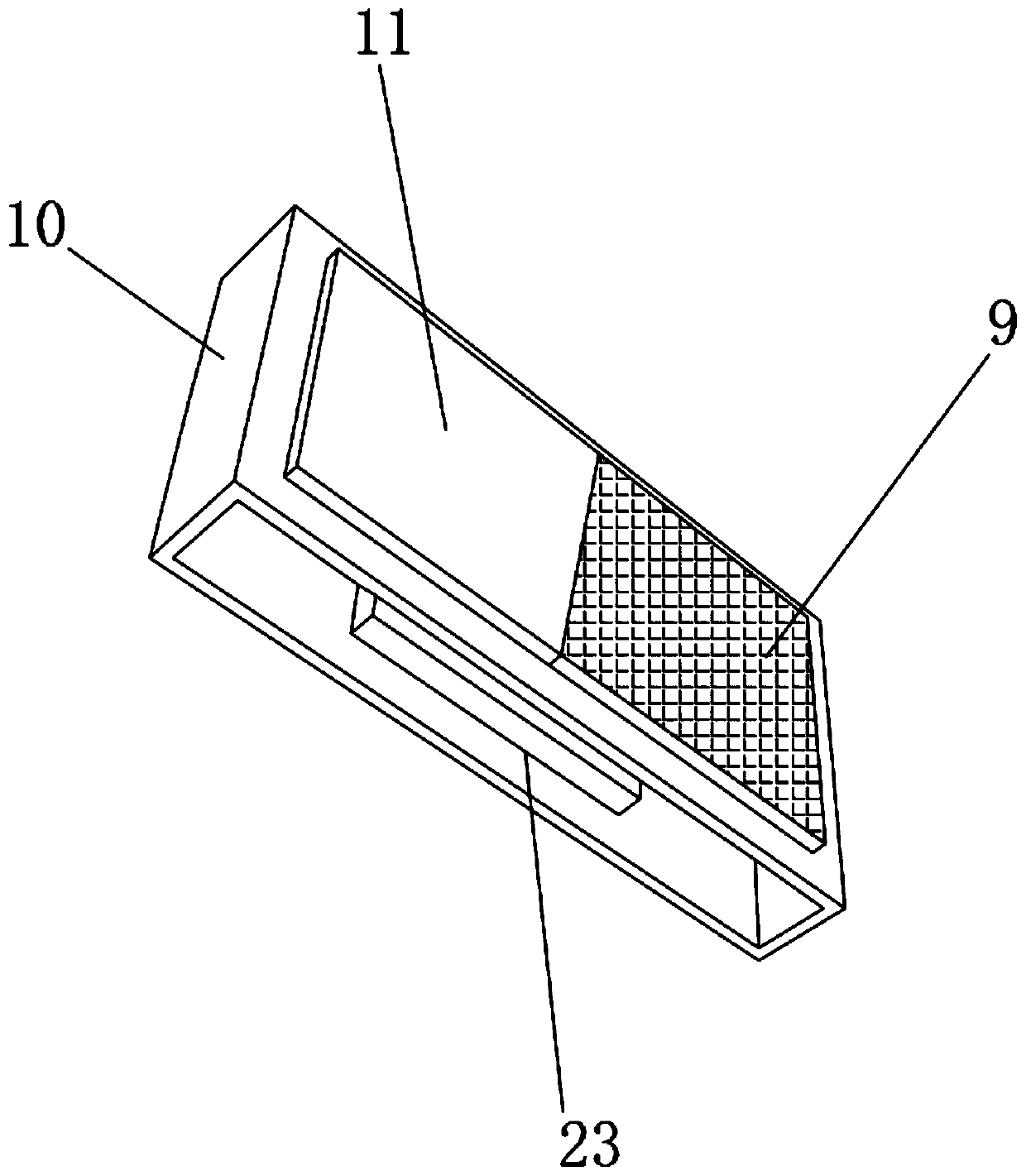

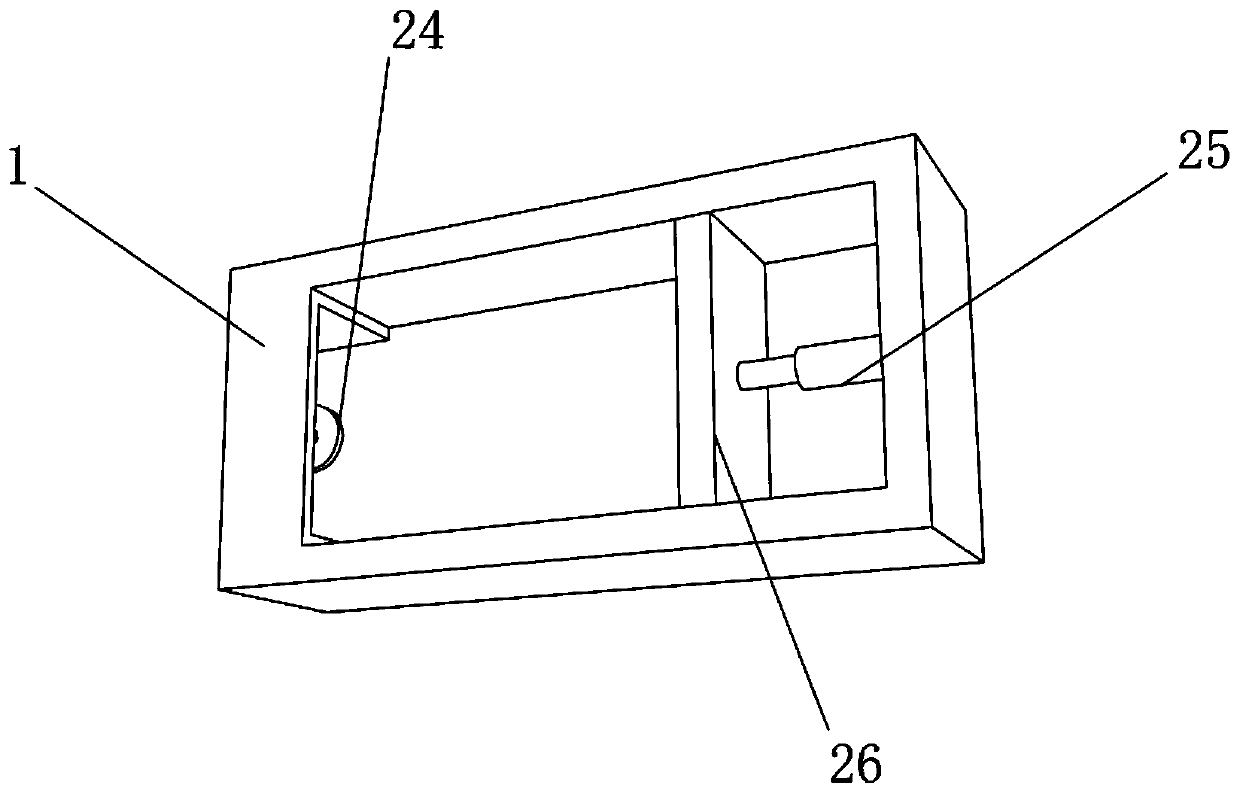

[0027] refer to Figure 1-4 , a drilling device for industrial machinery production, including a base 8, an L-shaped plate 15 is fixed on one side of the top outer wall of the base 8 by screws, and an electric telescopic rod 18 is fixed on the bottom outer wall of the L-shaped plate 15 by screws, and the electric telescopic One end of the rod 18 piston rod is fixed with a fixed block 20 by a screw, and the bottom outer wall of the fixed block 20 is provided with a fixed groove, the inner wall of the fixed groove is fixed with a motor 21 by a screw, and the output shaft of the motor 21 is connected with a drill bit through a coupling , one side outer wall of fixed block 20 is fixed with dust collection box 17 by screw, and the bottom outer wall of dust collection box 17 is fixed with dust suction pump 16 by screw, and the output end of dust suction pump 16 is connected with dust collection box 17, and The input end of the dust collection pump 16 is sleeved with a hose, and the ...

Embodiment 2

[0036] refer to Figure 5 , a kind of drilling equipment for industrial machinery production, compared with embodiment 1, also includes that the top outer wall of L-shaped plate 15 is fixed with solar panel 28 by screw, and the output end of solar panel 28 is connected with solar control by wire The output terminal of the solar controller is connected to the storage battery through wires.

[0037] When in use, the solar panel 28 can generate solar power and store the generated power through the battery to develop new energy, save energy and protect the environment, and conform to the concept of sustainable development of life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com