Cellulose/polypyrrole supported composite phase change heat storage material and preparation method thereof

A phase-change heat storage material and composite phase-change technology are applied in the field of cellulose/polypyrrole-supported composite phase-change heat storage materials and their preparation. High thermal efficiency, good biocompatibility and degradability, effects of improving thermal comfort and energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

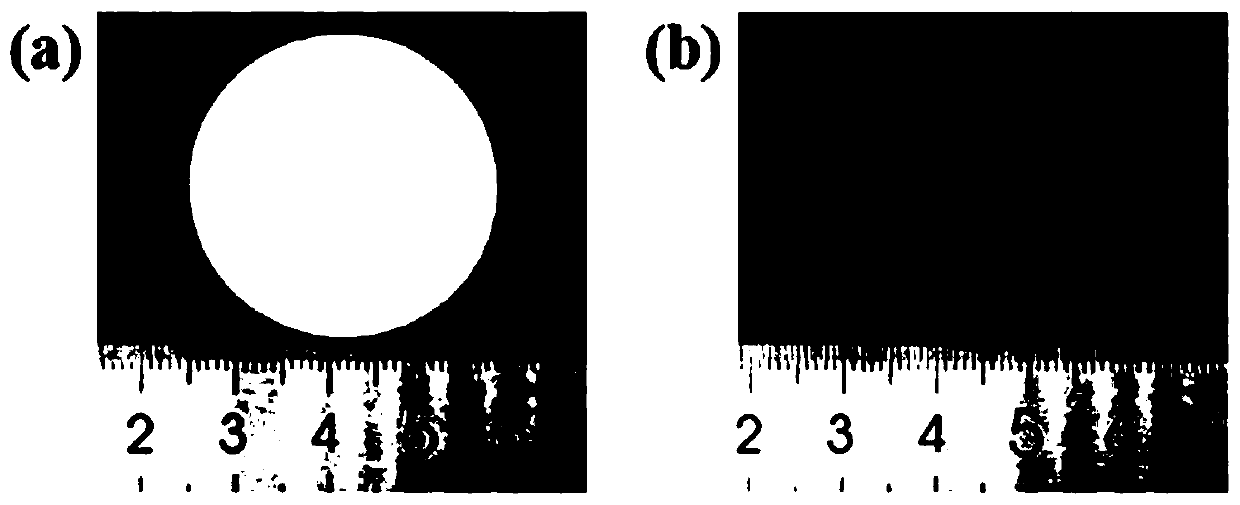

Image

Examples

Embodiment 1

[0028] (1) Weigh 20 g of cellulose nanowire suspension with a solid content of 1.2%, add KH560 dropwise to the cellulose nanowire suspension, and stir magnetically at room temperature for 3 hours to obtain a uniform mixed suspension, in which the cellulose nanowire The mass ratio to KH560 is 1:1; use deionized water to prepare a branched polyethyleneimine aqueous solution with a mass concentration of 25%, add it dropwise to the above suspension, and stir magnetically for 40 minutes at room temperature to obtain a uniform mixture Suspension, wherein the mass ratio of cellulose nanowires to branched polyethyleneimine is 1:0.8, and finally put the mixed suspension into a freeze dryer to freeze-dry, take it out and place it in an oven, and bake it at 110°C Bake for 30 minutes to obtain a cellulose porous material.

[0029] (2) Preparation 1 # Solution: Weigh 0.36M ferric chloride hexahydrate and 0.36M sodium 5-sulfosalicylate into 100mL deionized water, stir magnetically for 45mi...

Embodiment 2

[0033] (1) Weigh 20 g of cellulose nanowire suspension with a solid content of 1.0%, add KH560 dropwise to the cellulose nanowire suspension, and stir magnetically at room temperature for 2 hours to obtain a uniform mixed suspension, in which the cellulose nanowire The mass ratio to KH560 is 1:1.2; use deionized water to prepare a branched polyethyleneimine aqueous solution with a mass concentration of 50%, add it dropwise to the above suspension, and stir magnetically for 50 minutes at room temperature to obtain a uniform mixture Suspension, wherein the mass ratio of cellulose nanowires to branched polyethyleneimine is 1:0.8, and finally put the mixed suspension into a freeze dryer to freeze-dry, take it out and place it in an oven, and bake it at 120°C Dry for 20 minutes to obtain a cellulose porous material.

[0034] (2) Prepare 1# solution: Weigh 0.48M ferric chloride hexahydrate and 0.48M sodium 5-sulfosalicylate into 100mL deionized water, stir magnetically for 50min at ...

Embodiment 3

[0040] (1) Weigh 20 g of cellulose nanowire suspension with a solid content of 1.6%, add KH560 dropwise to the cellulose nanowire suspension, and stir magnetically at room temperature for 2 hours to obtain a uniform mixed suspension, in which the cellulose nanowire The mass ratio to KH560 is 1:0.8; use deionized water to prepare an aqueous solution of branched polyethyleneimine with a mass concentration of 50%, add it dropwise to the mixed suspension, and stir magnetically for 50 minutes at room temperature to obtain a uniform mixed suspension solution, in which the mass ratio of cellulose nanowires to branched polyethyleneimine is 1:1. Finally, the mixed suspension was put into a freeze dryer to freeze-dry, taken out and placed in an oven, and baked at 130° C. for 10 minutes to obtain a cellulose porous material.

[0041] (2) Preparation of 1# solution: Weigh 0.60M ferric chloride hexahydrate and 0.60M sodium 5-sulfosalicylate into 100mL deionized water, stir magnetically for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com