Easy-to-draw tire cord steel coil rod and production method

A production method and technology for steel wire rods, which are applied in the field of cord steel production, can solve the problem that cord steel cannot be well adapted to high-speed drawing, etc., and achieve the effects of improving drawing speed, improving cleanliness, and excellent drawing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

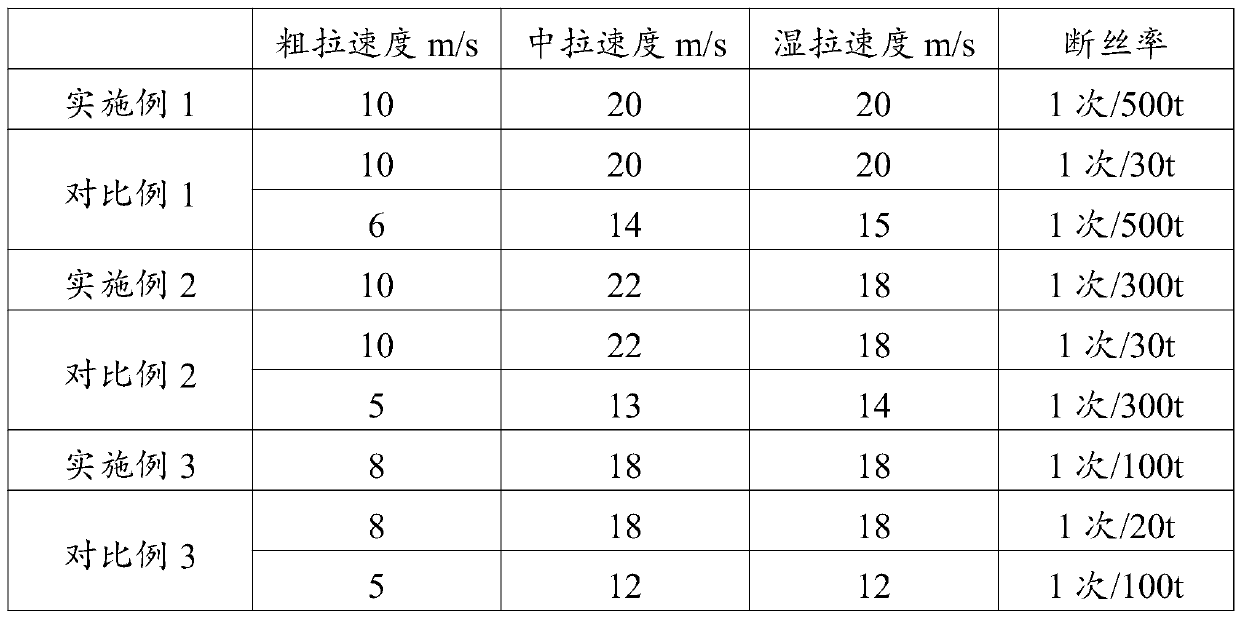

Embodiment 1

[0018] This embodiment provides a kind of easy-drawn cord steel LX72A wire rod, LX72A wire rod network cementite grade 0, sorbite rate of 98%, proeutectoid ferrite of 0.1%, strength fluctuation range of 12MPa; the defect depth on the surface of the wire rod is 0.02mm, and the defect ratio is 0.1%. The production method of easy-drawn cord steel LX72A wire rod. Including hot metal KR desulfurization, converter steelmaking, LF refining, bloom continuous casting, blooming, grinding, rolling. Specific steps are as follows:

[0019] Hot metal KR desulfurization process:

[0020] Hot metal before desulfurization: temperature is 1360°C, S content is 0.04%, Ti content is 0.08%; hot metal after desulfurization: temperature is 1310°C, S content is 0.004%, Ti content is 0.09%.

[0021] Converter smelting process:

[0022] The molten iron ratio is 90%; the S content of steel scrap is 0.020%, the Ti content is 0.008%, and the Al content is 0.025%. When adding alloy material and slag ma...

Embodiment 2

[0032] This embodiment provides an easy-draw cord steel LX82A wire rod, the wire rod network cementite is 0.5 grade, the sorbite rate is 99%, the proeutectoid ferrite is 0.1%, and the strength fluctuation range is 13MPa ; The surface defect depth of the wire rod is 0.03mm, and the defect ratio is 0.3%.

[0033] The production method of easy-drawn cord steel LX82A wire rod. Including hot metal KR desulfurization, converter steelmaking, LF refining, bloom continuous casting, blooming, grinding, rolling. Specific steps are as follows:

[0034] Hot metal KR desulfurization process:

[0035] Hot metal before desulfurization: temperature is 1365°C, S content is 0.035%, Ti content is 0.06%; hot metal after desulfurization: temperature is 1311°C, S content is 0.003%, Ti content is 0.07%.

[0036] Converter smelting process:

[0037] The molten iron ratio is 91%; the S content of scrap steel is 0.015%, the Ti content is 0.01%, and the Al content is 0.020%; the final slag basicity o...

Embodiment 3

[0047] This embodiment provides an easy-draw cord steel LX86A wire rod, the wire rod network cementite is 1.0, the sorbite rate is 99%, the proeutectoid ferrite is 0.1%, and the strength fluctuation range is 15MPa ; The surface defect depth of the wire rod is 0.02mm, and the defect ratio is 0.4%. The rough drawing speed is 8m / s, the intermediate drawing speed is 18m / s, the wet drawing speed is 18m / s, and the broken wire rate is 1 time / 100t.

[0048] The production method of easy-drawn cord steel LX86A wire rod. Including hot metal KR desulfurization, converter steelmaking, LF refining, bloom continuous casting, blooming, grinding, rolling. Specific steps are as follows:

[0049] Hot metal KR desulfurization process:

[0050] Hot metal before desulfurization: temperature is 1360°C, S content is 0.04%, Ti content is 0.07%; hot metal after desulfurization: temperature is 1308°C, S content is 0.004%, Ti content is 0.06%.

[0051] Converter smelting process:

[0052] The molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com