Fan structure capable of increasing air inlet amount, evaporator component capable of increasing air inlet amount and noise reduction humidifier

A technology of air intake and humidifier, applied in air humidification system, components of pumping device for elastic fluid, pump components, etc., can solve the high water quality requirements of ultrasonic atomizing humidifiers and high safety performance requirements of electric heating humidifiers , The humidification rate of the humidifier is not high, etc., to achieve the effect of ensuring the humidification efficiency, improving the stability of the air supply, and reducing the setting of the air duct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

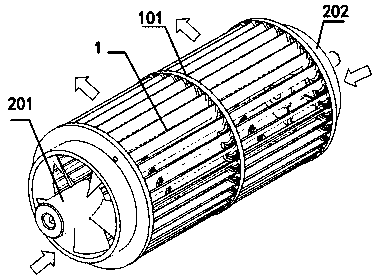

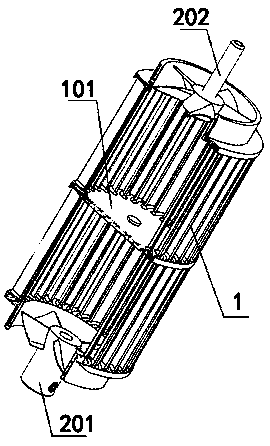

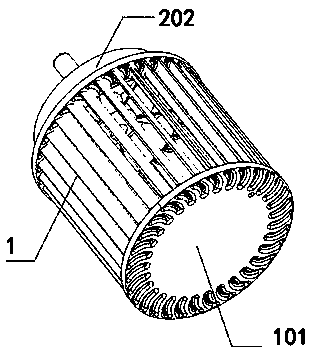

[0040] refer to figure 1 , figure 2 , image 3 As shown, one embodiment of the present invention is a fan structure for increasing air intake, including a cross-flow fan 1, wherein the cross-flow fan 1 is an existing cross-flow fan, and the air flow passes through the impeller of the cross-flow fan 1 to realize air supply. Because the blades of the cross-flow fan 1 are subjected to two forces, the airflow can reach a long distance, but the airflow is forced to turn inside the impeller, so the pressure head loss is relatively large, resulting in low air supply efficiency. The fan 1 is provided with an air supply area, through which the air flow is poured, so that the blades of the cross-flow fan 1 can take away part of the air flow once a force is applied, thereby improving the air supply efficiency.

[0041] Normally, in order to ensure sufficient air supply, the impeller of the cross-flow fan 1 needs to run at high speed. However, when the impeller rotates, the airflow ent...

Embodiment 2

[0044] Based on the above-mentioned embodiment, another embodiment of the present invention is that the middle part of the cross-flow fan 1 is provided with a baffle 101, wherein the baffle 101 has a plurality of blade openings, and the baffle 101 is inserted into the cross-flow fan through the blade openings. 1, and fixed in the middle of the cross-flow fan 1, the baffle 101 is used to form two air supply areas inside the cross-flow fan 1.

[0045] Among them, there are many ways to fix the baffle 101, such as hot melt glue fixing, pin limit, etc.; through two air supply areas corresponding to the first axial flow fan 201 and the second axial flow fan 202, the first axial flow The airflow conveyed by the fan 201 and the second axial flow fan 202 enters different air supply areas without affecting each other, preventing the first axial flow fan 201 and the second axial flow fan 202 from reversely conveying the airflow and causing turbulent flow in the air supply area; thus It is...

Embodiment 3

[0047] Based on the above examples, refer to figure 1 As shown, another embodiment of the present invention is that the first axial flow fan 201 and the second axial flow fan 202 are coaxially arranged with the cross flow fan 1, wherein the first axial flow fan 201 and the second axial flow fan 202 It is an existing axial flow fan, and its first axial flow fan 201 and second axial flow fan 202 outer diameter size is compatible with the cross flow fan 1 side wall inner diameter size, and its first axial flow fan 201 and second axial flow fan The blades of 202 are directed in the opposite direction, so that when the blades of the first axial flow fan 201 and the blades of the second axial flow fan 202 rotate in the same direction, the direction of gas flow is opposite; The blower fan 1, the first axial flow fan 201 and the second axial flow fan 202 rotate; when the first axial flow fan 201, the second axial flow fan 202 and the cross flow fan 1 are coaxially arranged, the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com