Portable detection device for blockage of exposed filling pipeline, and dredging method

A technology for detection devices and pipelines, which is applied in the directions of measuring devices, geophysical measurements, and processing detection response signals, etc., which can solve problems such as limiting the conveying speed of filling materials, reducing filling efficiency, and interruption of construction, and achieve rapid and efficient dredging and dredging effects Good, high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

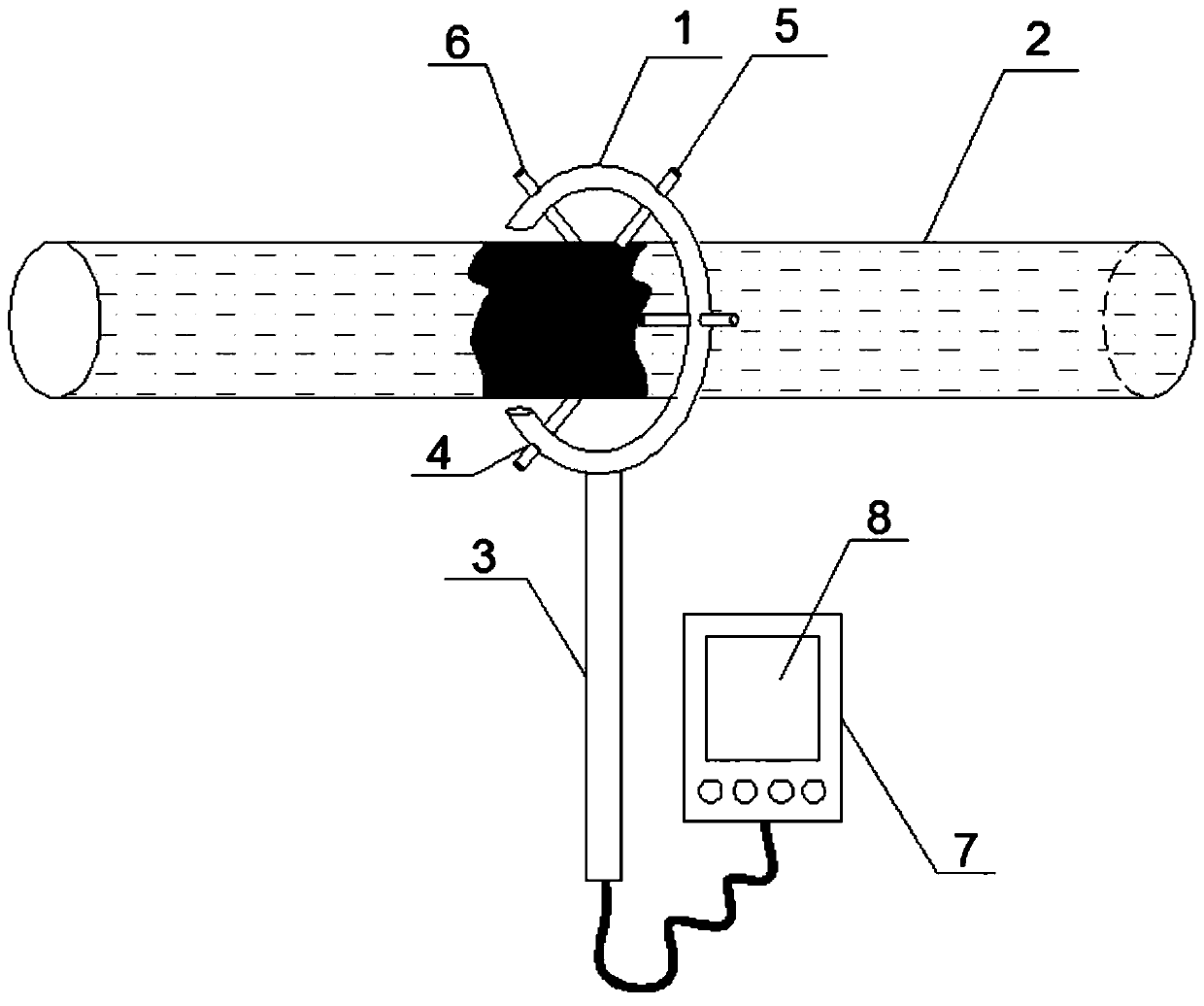

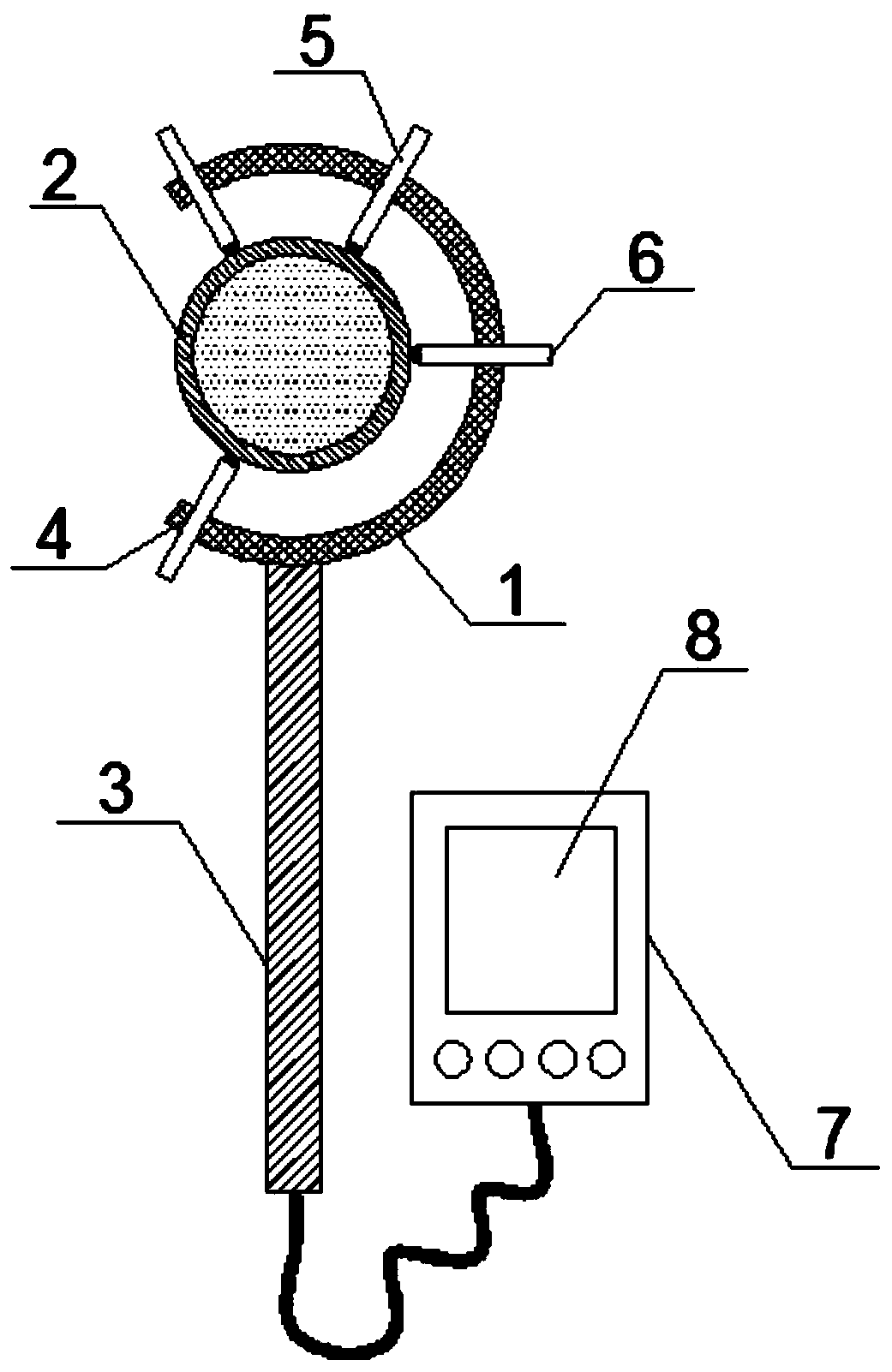

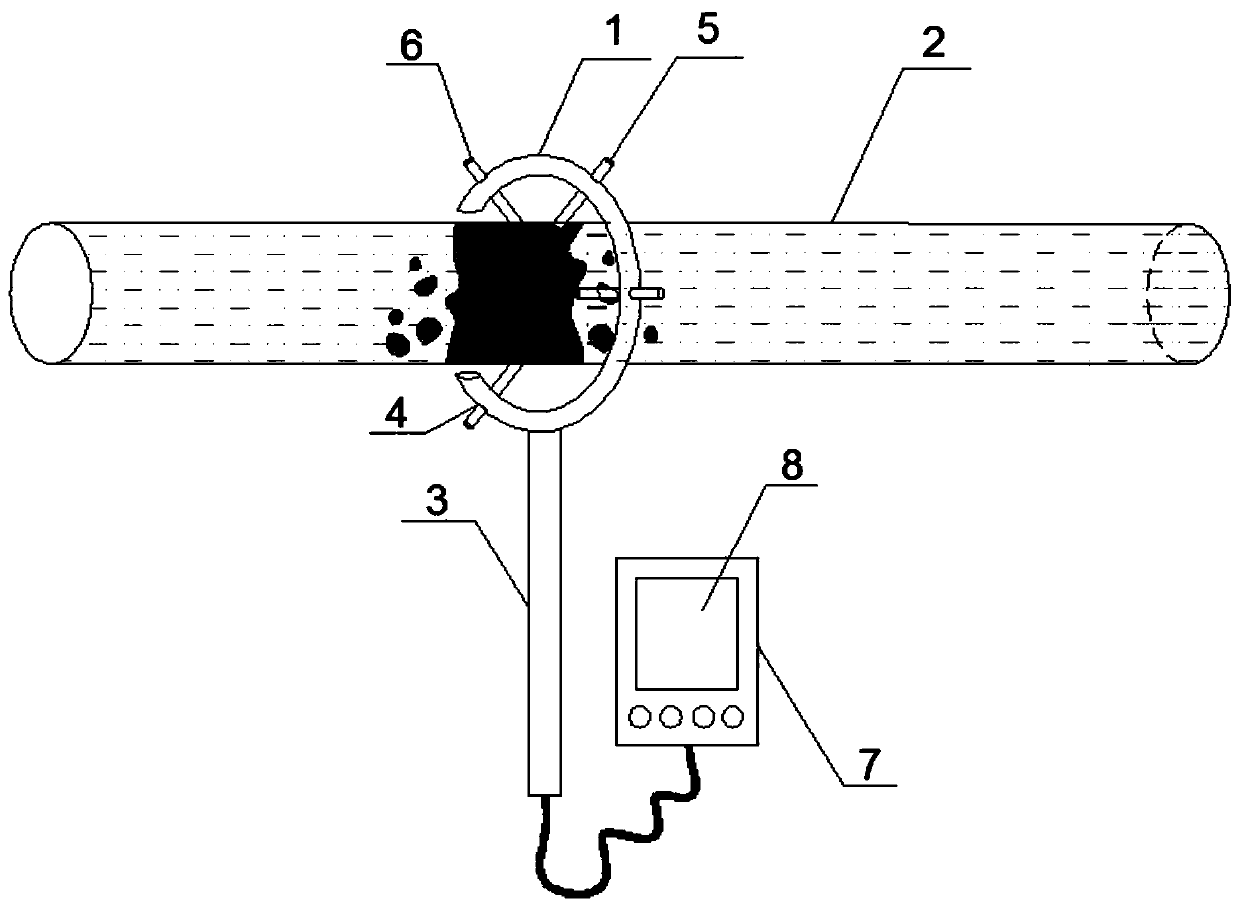

[0033] Such as figure 1 with figure 2 As shown, a portable detection device for the blockage of an exposed filling pipeline includes a C-shaped split ring 1 whose width at the open end is not less than the outer diameter of the pipe 2, and the inner diameter of the split ring 1 is greater than the outer diameter of the pipe 2; the lower end of the split ring 1 connected with handle 3;

[0034] A plurality of threaded mounting holes 4 are provided on the split ring 1, and an ultrasonic receiving probe 5 is installed in one of the mounting holes 4, and ultrasonic resonance contacts 6 are respectively installed in the remaining mounting holes 4. The ultrasonic receiving probe 5 and the ultrasonic wave The resonance contact 6 is slidingly matched with the outer wall of the pipeline 2; the ultrasonic receiving probe 5 and the ultrasonic resonance contact 6 are both connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com