2D Predictive Fault-Tolerant Control Method for Batch Processes with Time Delay and Disturbance

A fault-tolerant control and time-delay technology, applied in the directions of adaptive control, general control system, control/regulation system, etc., can solve the problems of influence and increase the difficulty of the controller, and achieve a small amount of calculation, simple structure, and guaranteed stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

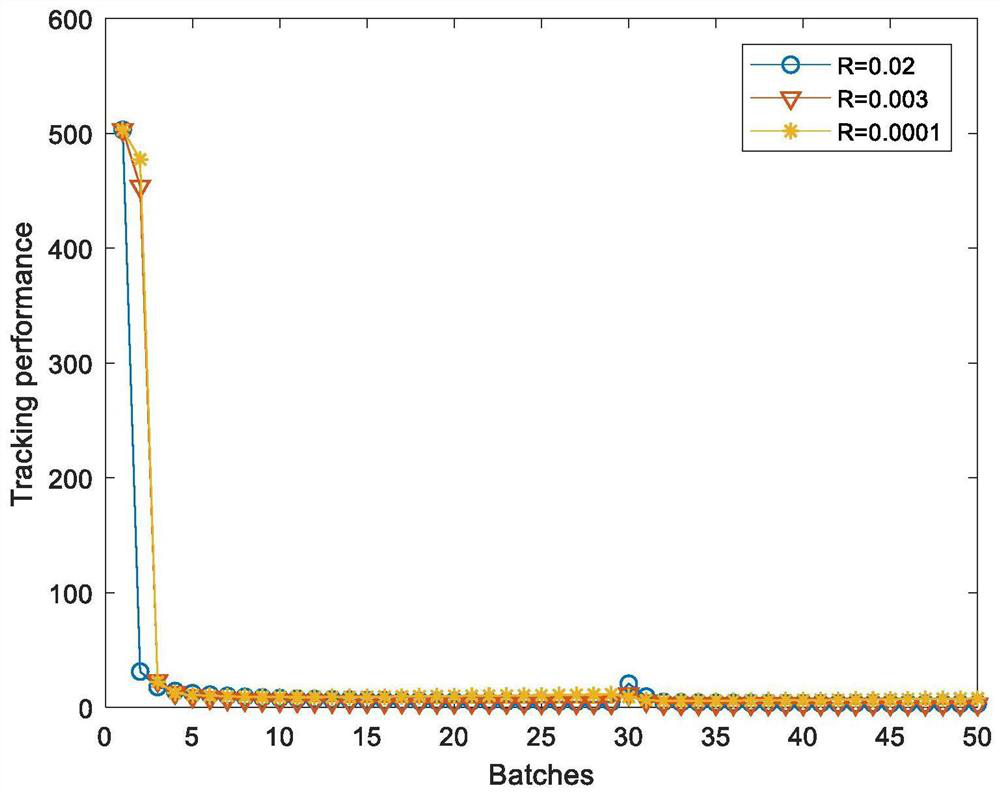

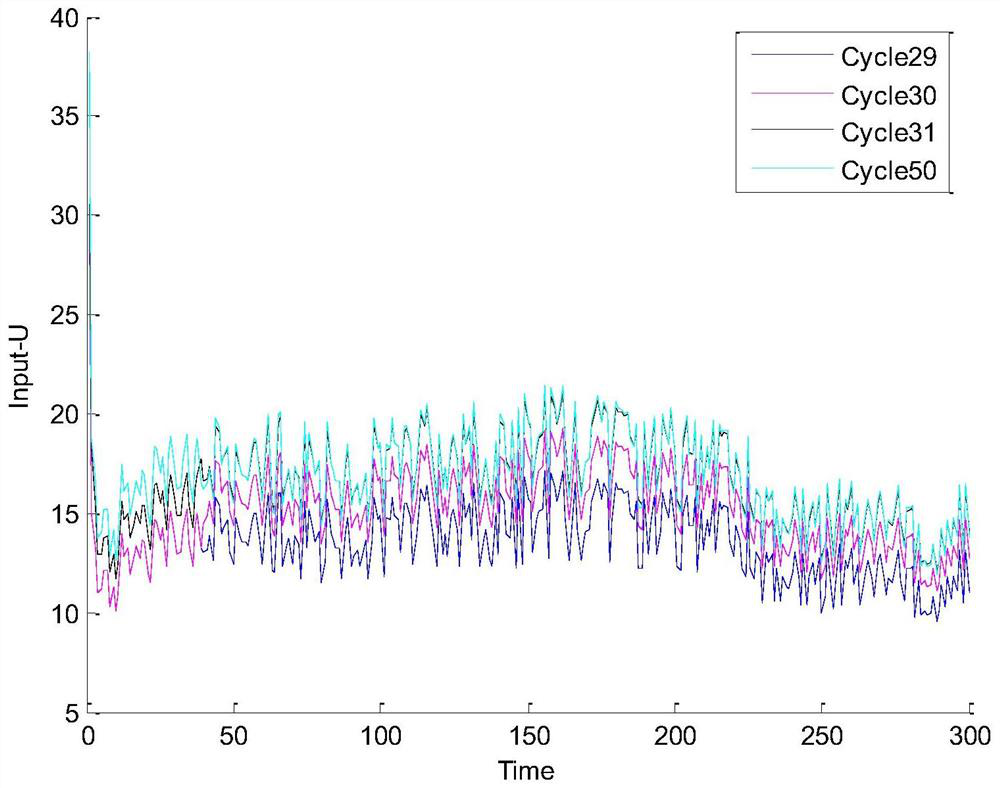

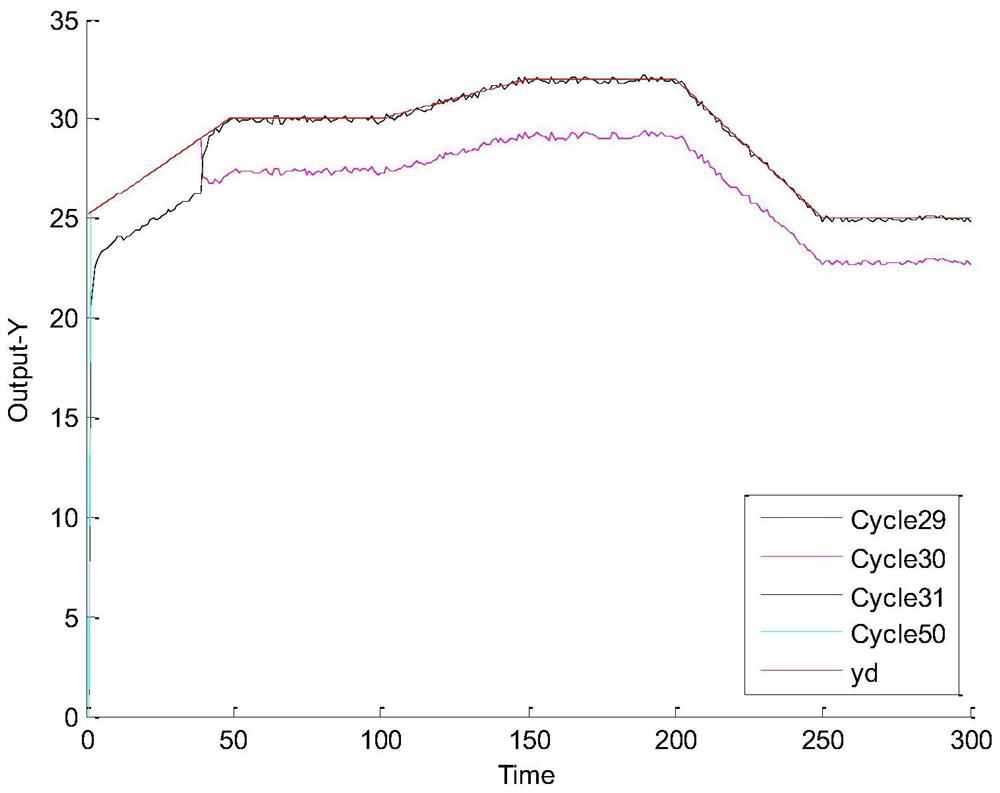

Examples

Embodiment 1

[0120] The present invention considers the following nonlinear continuous stirred tank for simulation, including the following two differential equations

[0121]

[0122]

[0123] Among them, C A is the concentration of A in the irreversible reaction process (A→B); T is the temperature of the reactor; T j is the temperature of the cooling stream. as an operating variable, k 0 =2.53×10 19 (1 / molmin), E / R=13,500(K), T(0)=25(℃), C A (0)=0.9 (mol / L).

[0124]For system identification, a transfer test at 26°C with a sampling interval of 1 was performed. Therefore, we can get the transfer model

[0125] Assuming the system is second order, a least squares method with transitive inputs and transitive responses is used. x 1 (t,k)=y(t,k) x 2 (t,k)=-0.0013y(t-1,k)+0.0425u(t-1,k). The transfer function can be transformed into the following state-space model:

[0126]

[0127] After discretization, the time-delay extension model of the above state-space model can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com