A coupling cavity traveling wave tube energy transmission structure and its assembly method

An assembly method and traveling wave tube technology, which are applied to the coupling device of transit time type electron tubes, the manufacture of discharge tubes/lamps, the manufacture of electrode systems, etc., can solve the problems that the reliability of components cannot meet the use requirements of traveling wave tubes, etc. To achieve good air tightness, ensure the use of requirements, the system impedance matching effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

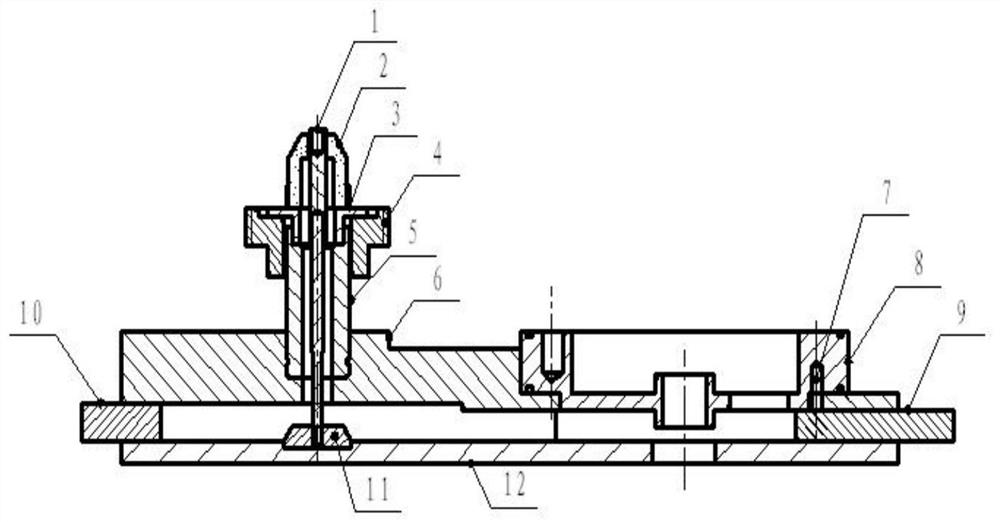

[0035] Such as figure 1 As shown, a coupling cavity traveling wave tube energy transmission structure, which includes: an inner conductor 1, a window ceramic 2 welded outside the inner conductor 1, a sealing ring 3 welded on the lower end of the window ceramic 2, a sealing ring 3 welded on the The outer conductor 5 at the lower end, the fastening screw sleeve 4 set outside the sealing ring 3 and the outer conductor 5;

[0036] The lower end of the inner conductor 1 passes through the window porcelain 2, the sealing ring 3 and the outer conductor 5 and is then inserted into the antenna slot provided on the waveguide cover plate 12. A circular antenna 11 is placed in the antenna slot, and the lower end of the inner conductor 1 passes through the antenna slot. Fix in the antenna slot after crossing the circular antenna 11;

[0037] After the lower end of the outer conductor 5 and the contact surface of the impedance transformer 7 are riveted along the circumference, they are wel...

Embodiment 2

[0041] Such as Figure 2 to Figure 9 , a method for assembling an energy transmission structure of a coupled cavity traveling wave tube, comprising the following steps:

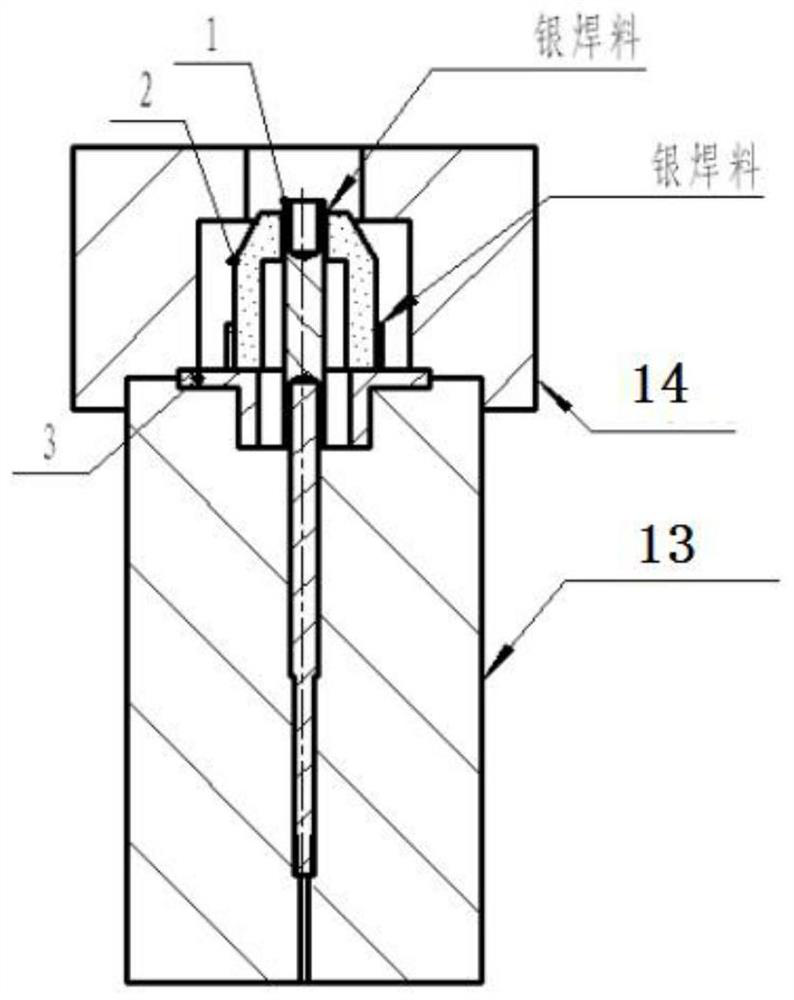

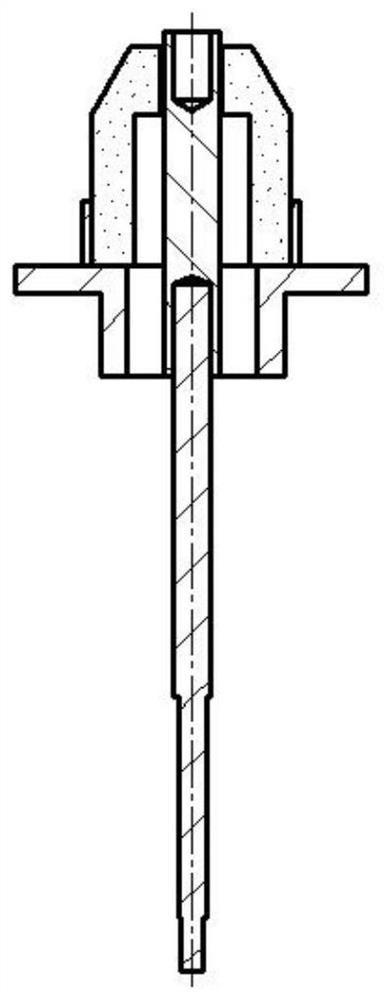

[0042] Step a: First place the sealing ring 3 in the first welding mold 13, then put the window ceramic 2 outside the inner conductor 1, place the window ceramic 2 on the sealing ring 3, and let the lower end of the inner conductor 1 pass through After the sealing ring 3 is inserted into the first welding mold 13; then the second welding mold 14 is put on the first welding mold 13, and the second welding mold 14 is placed on the outer periphery of the window porcelain 2; then the inner conductor 1, the sealing ring 3 and the window porcelain 2 are welded by silver brazing, and assembled to obtain the window assembly;

[0043] Step b: Place the outer conductor 5 in the third welding mold 15, then place the window combination part in step a on the outer conductor 5, and put the fourth welding mold 16 on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com