Method and system for forming quasi-crystal coating and cookware

A coating and quasi-crystal technology, applied in the field of material science, can solve the problems of non-stick coatings that need to be improved, and achieve the effects of excellent surface properties, low friction coefficient and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

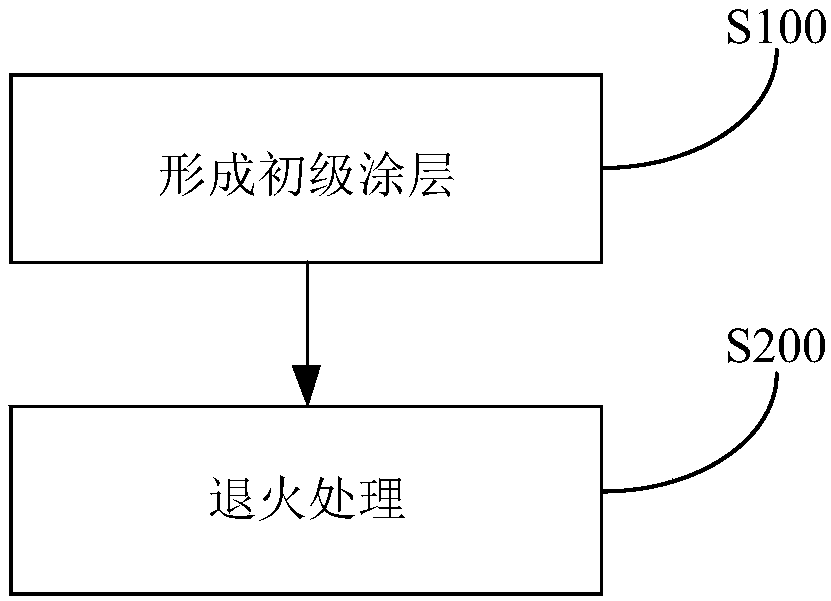

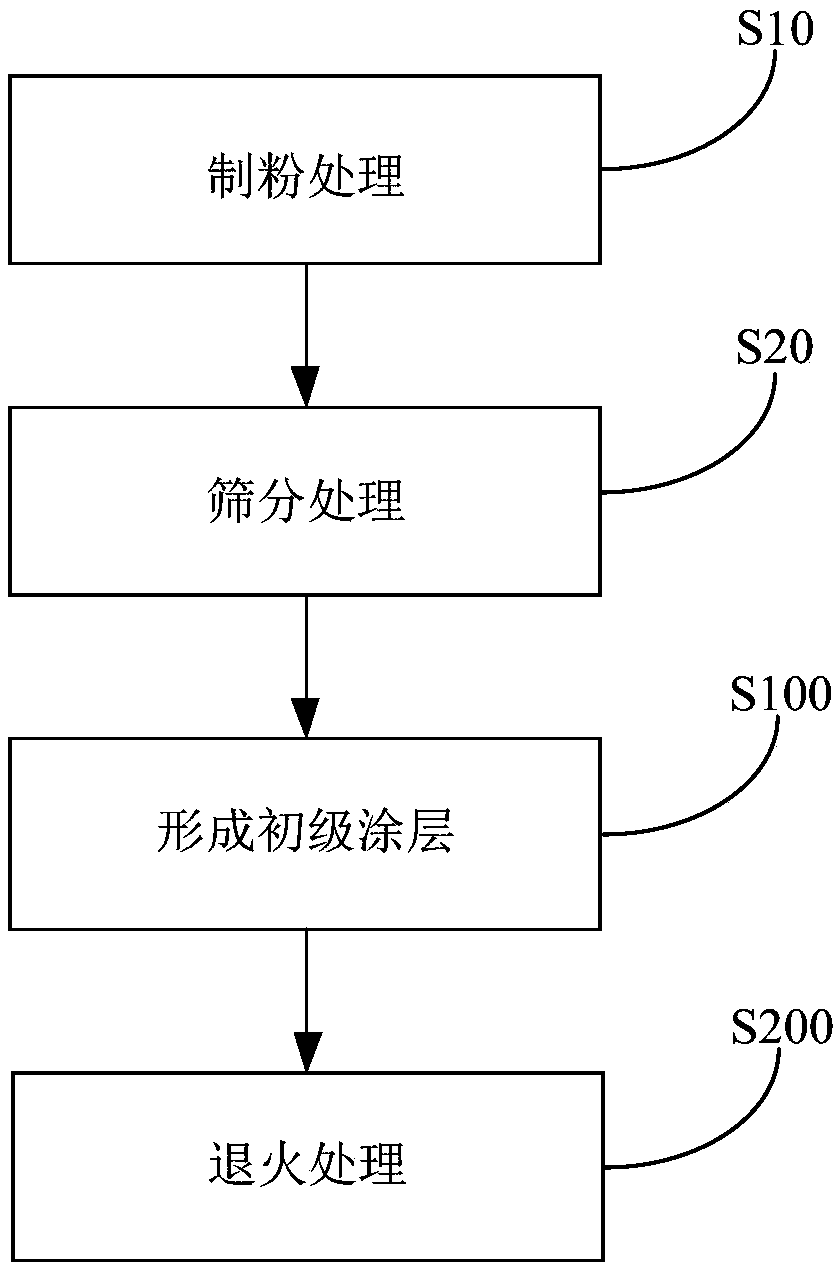

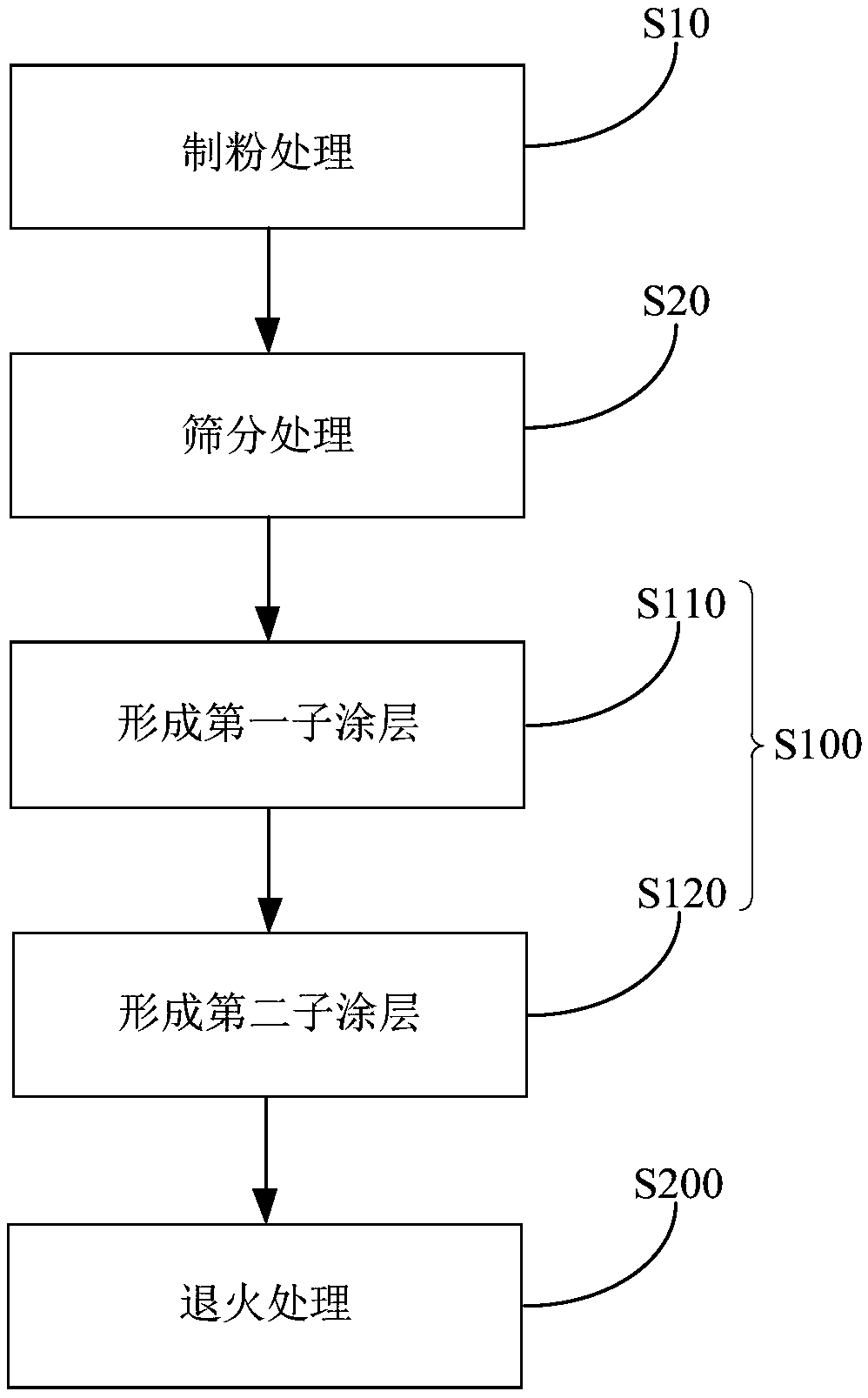

[0148] Follow the steps below to form a quasicrystalline coating:

[0149] (1) Using pure aluminum, pure copper, pure iron and pure chromium as raw materials, according to the atomic ratio of aluminum: 60-70%, copper: 15-25%, iron: 5-15%, chromium: 5-15, respectively ingredients.

[0150] (2) Put the weighed raw materials into an intermediate frequency induction furnace for smelting treatment, wherein iron and chromium are placed at the bottom of the intermediate frequency induction furnace. During the smelting process, an inert gas is used as a protective gas or the furnace is evacuated. After the alloy is completely melted and the slag is removed, the quasicrystalline alloy ingot is cast.

[0151] (3) The quasicrystalline alloy ingot is supplied to the atomization powder making device for atomization and powder making, and the whole process is protected by inert gas or the system is evacuated to obtain the quasicrystalline alloy powder.

[0152] (4) Supply the quasicrystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com