Swing-pacing type robot and control system thereof

A control system and robot technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of high market price, excess load capacity performance, and difficult maintenance, etc., to reduce the difficulty and complexity of manipulation, movement and dynamics The effect of suitable characteristics and light moving components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

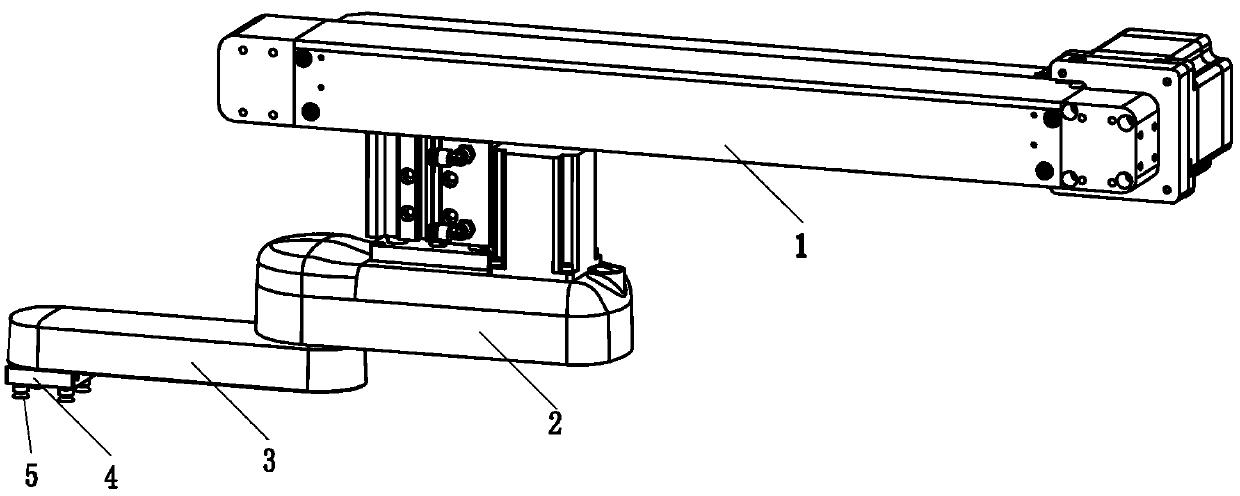

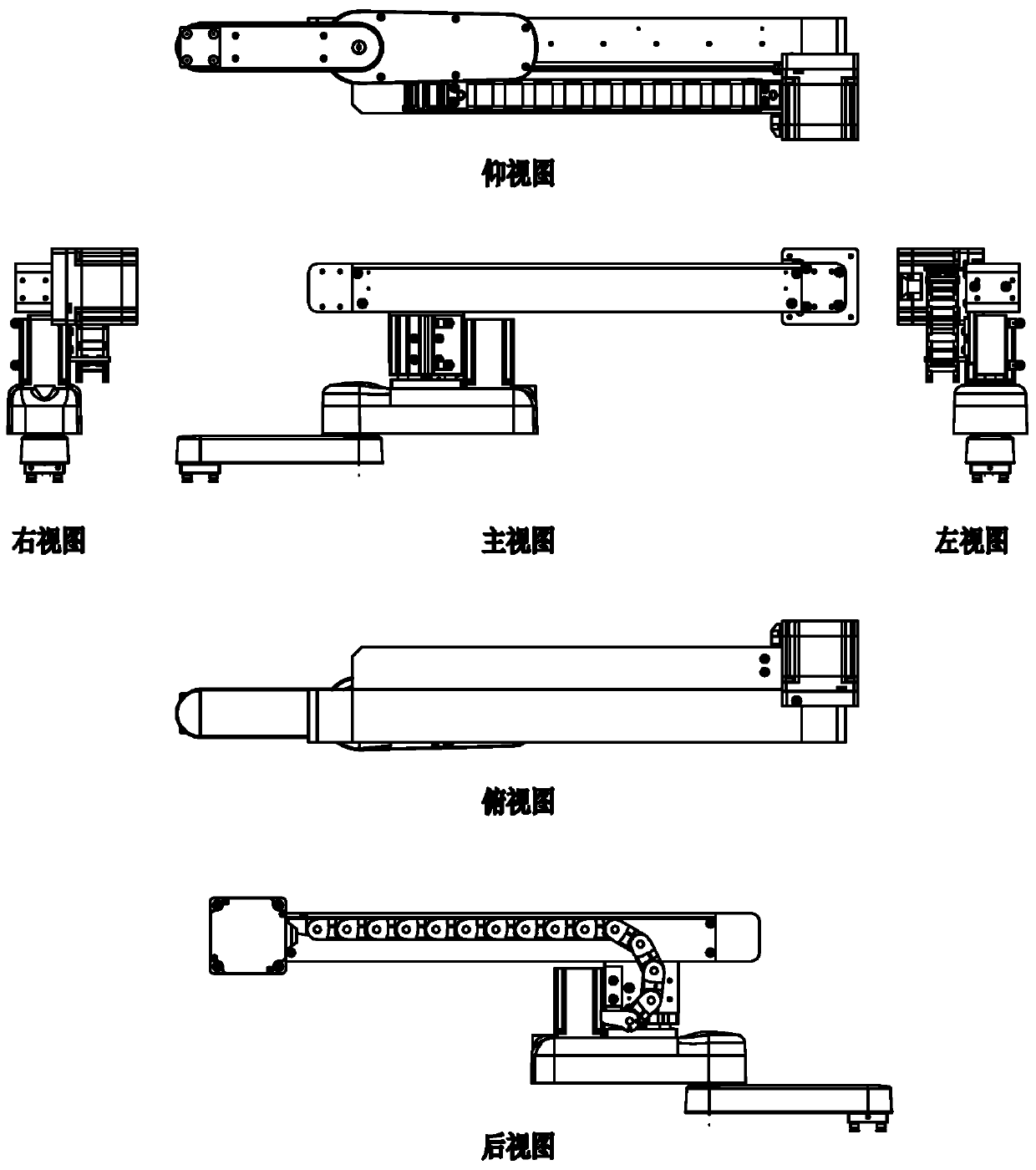

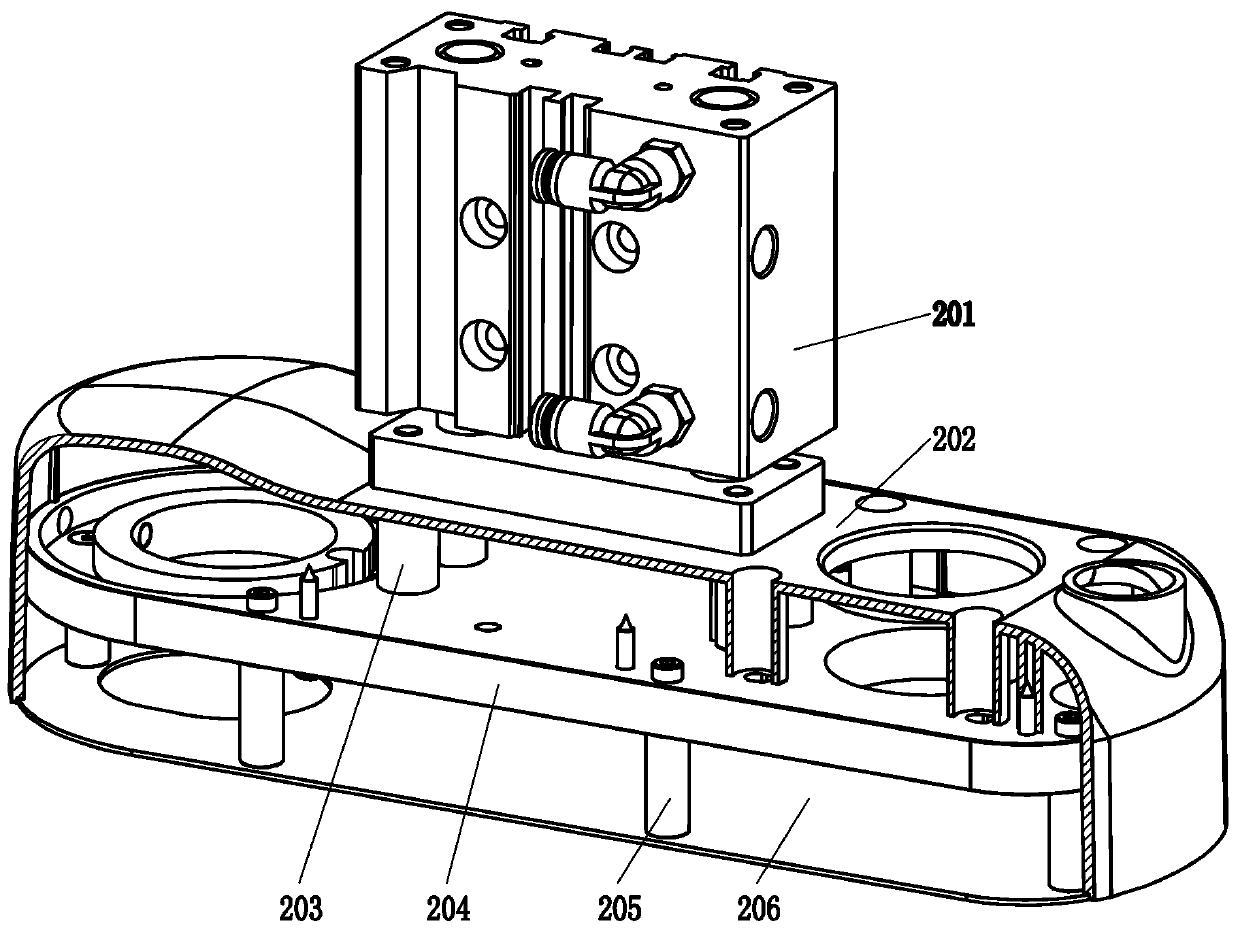

[0027] refer to Figure 1 to Figure 3 As shown, the present invention provides a swing-type robot and its control system, which are applied to the field of work automation plane operations, and are especially suitable for applications such as thermal pressing, indentation, hot stamping, punching, grinding, laser engraving, storage, up and down, etc. Lines, etc. include but are not limited to the above-mentioned production situations of supplying and receiving materials with mold positioning or secondary positioning or free positioning. The present invention includes X-axis 1 for linear motion, Z-axis 2 for lifting motion, U-axis 3 for free rotation, W-axis 4 for 90-degree rotation and hidden slip ring air circuit 5, and is equipped with a set of user-oriented electrical control system.

[0028] X-axis 1 of the linear motion, refer to Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com