Cooling sizing device and method for hot melting glue preparing and machining

A technology for cooling and shaping, hot-melt adhesive, applied in chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

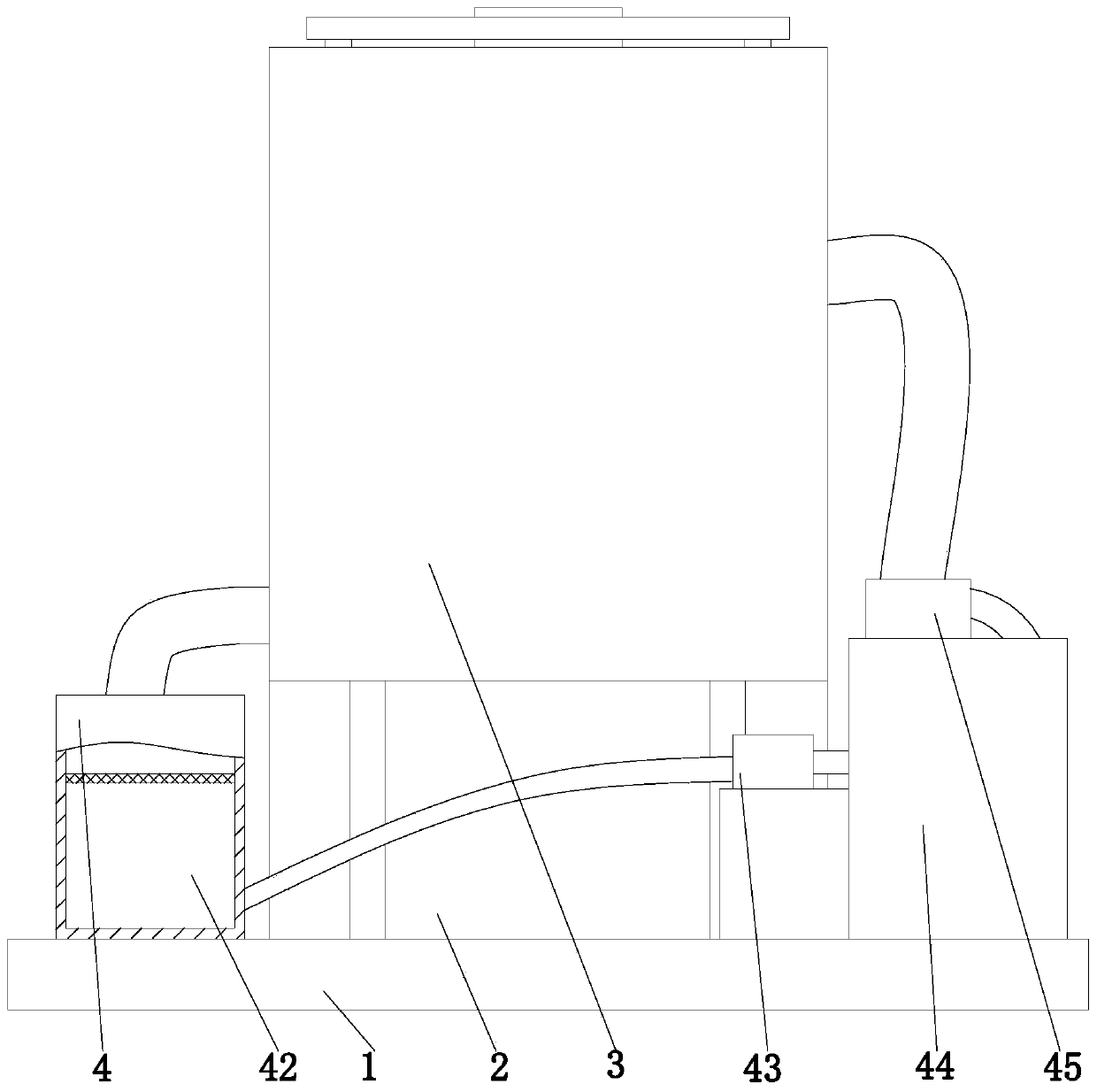

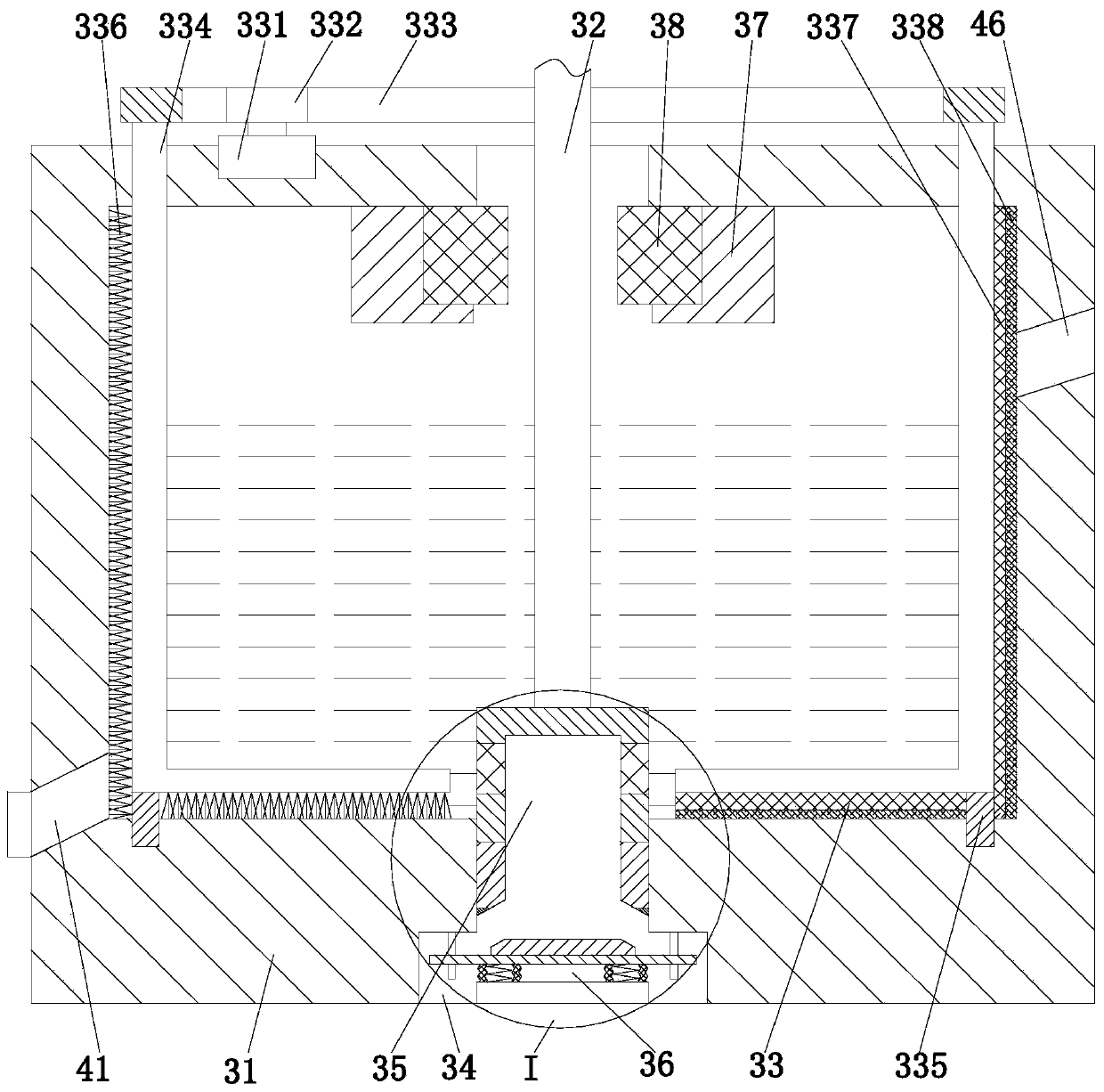

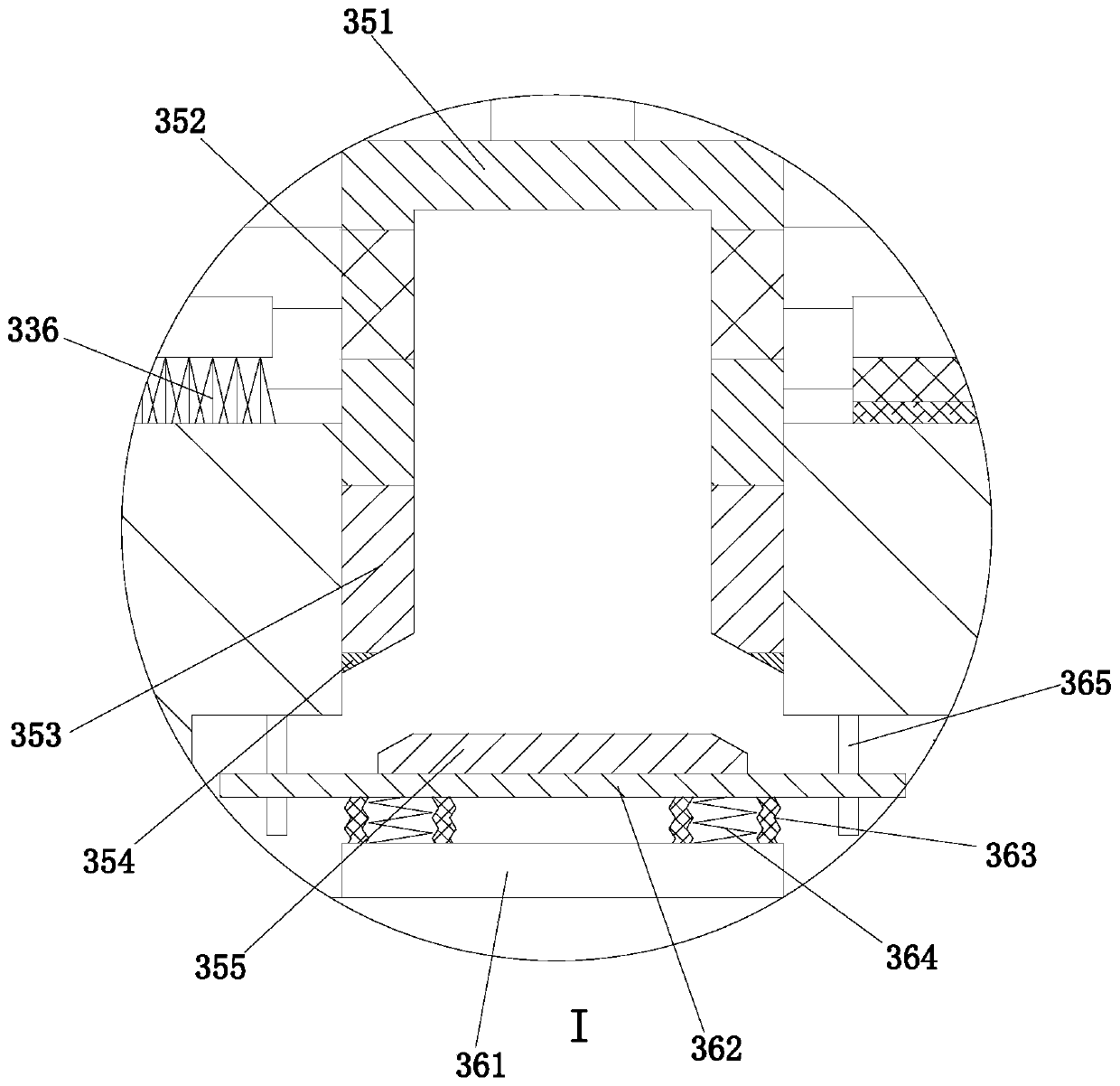

[0027] like Figure 1 to Figure 3 As shown, a hot melt adhesive preparation, processing, cooling and shaping device includes a base 1, a glue discharging unit 2, a shaping unit 3 and a cooling circulation unit 4, and the upper end of the base 1 is equipped with a glue discharging unit 2 and a cooling circulation unit 4, The sizing unit 3 is installed on the upper end of the gluing unit 2, and the outer wall of the sizing unit 3 is connected with a cooling circulation unit 4 through a pipeline; the gluing unit 2 injects hot melt glue into the sizing unit 3, and the sizing unit 3 makes the hot melt glue into a glue stick and The inner wall of the cooling cylinder 31 is cleaned, and the cooling circulation unit 4 replaces the cooling fluid in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com