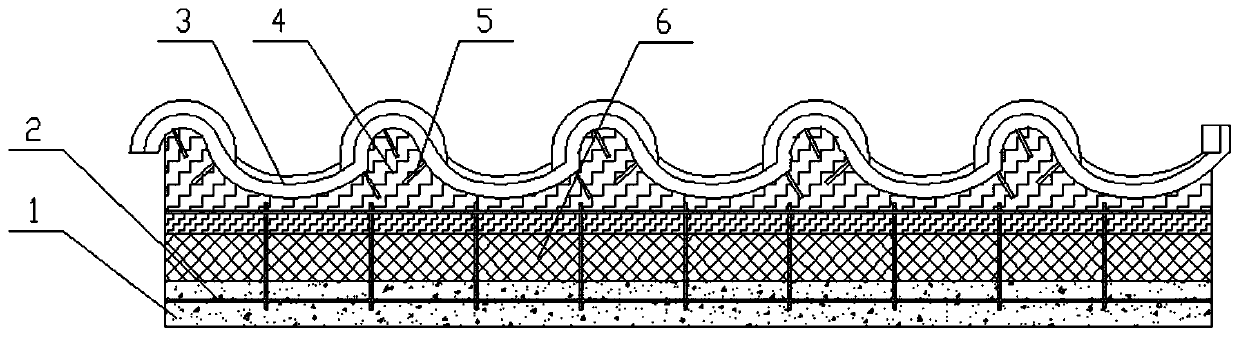

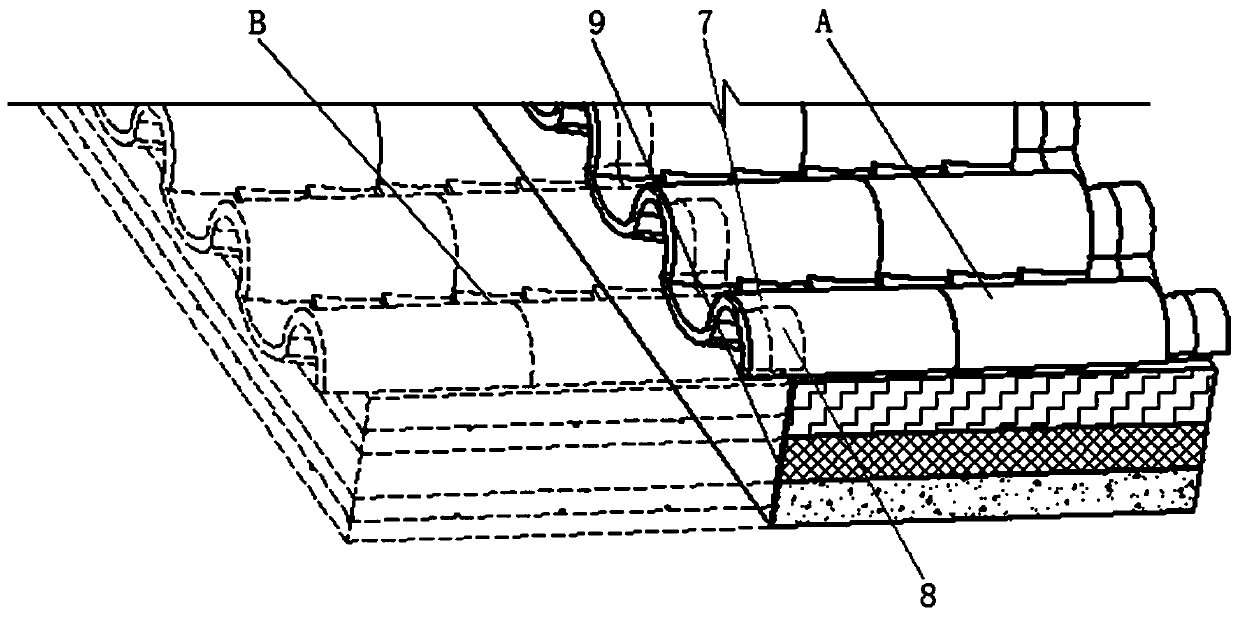

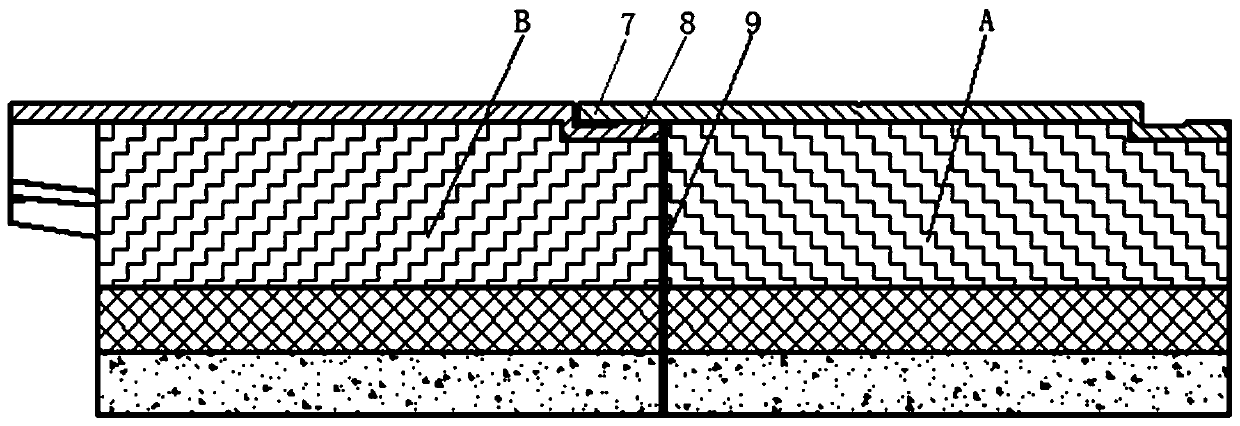

Roof tile and roof thermal insulation integrated roof member, manufacturing method and installing method

A technology of roof components and roof tiles, applied in the direction of manufacturing tools, roof coverings, surface layering devices, etc., can solve problems such as inconvenient installation, work protection restrictions, construction work support and transportation conditions, and save manpower and cost , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] When installing, the roof component of the present invention also needs to be used in conjunction with other special components, such as roof ridge, side wall and cornice. Those skilled in the art can combine various material bases according to the present invention to obtain integrated roof components with different requirements. Typical examples are shown in Table 1.

[0072] Table 1

[0073]

[0074]

[0075] In Table 1, the surface-modified cement polyphenylene particles are materials obtained by modifying polyphenylene particles to obtain good bonding strength with cement, such as the commercially available product with the trademark "Concrete Granules". Rubber powder cement polyphenylene particles are a certain type of product, that is, rubber powder polystyrene particle slurry in JG / T 158 "Materials for Exterior Wall External Thermal Insulation System of Rubber Powder Polystyrene Granules". Type Ⅱ-B polyurethane refers to type Ⅱ-B polyurethane that meets t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com