Efficient desulfuration and denitration method for coal combustion

A coal combustion and high-efficiency technology, applied in the direction of combustion method, fuel burned in molten state, combustion type, etc., can solve the problems such as difficult to meet the NOx emission standards, and achieve the effect of increasing the reaction speed, improving the completion degree, and improving the contact completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

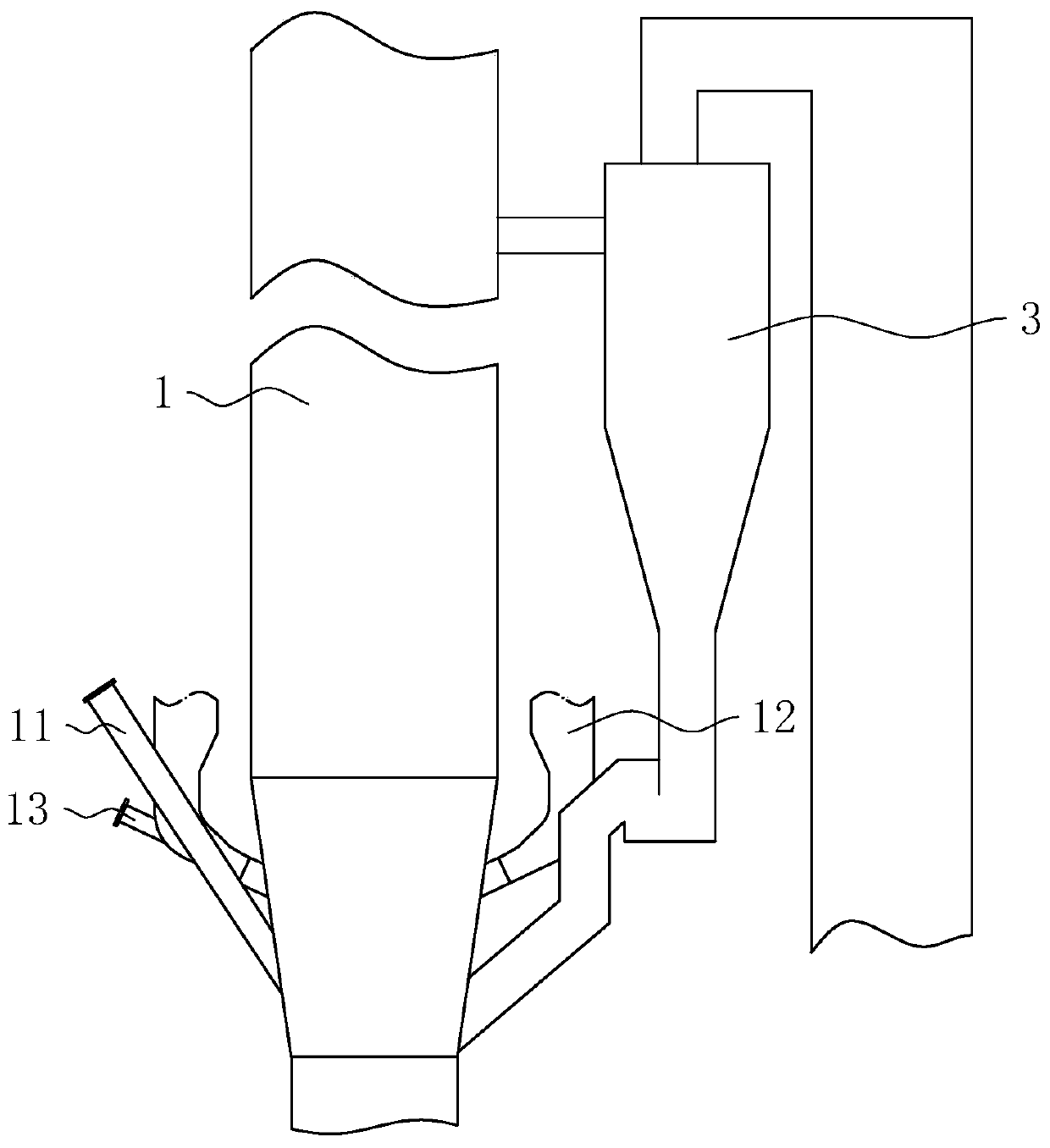

[0039] A method for efficient desulfurization and denitrification of coal combustion, referring to figure 1 , including the following steps: coal enters from the circulating fluidized bed boiler for combustion, the circulating fluidized bed boiler includes a furnace 1 for burning coal, the furnace 1 is in a cylindrical shape, a coal inlet pipe 11 and a secondary air pipe 12 are installed at the lower end of the furnace 1, The side wall near the top of the furnace 1 is provided with an outlet, the outlet is connected with a cyclone separator 3 , and the secondary air pipe 12 is also connected with a feed pipe 13 . The desulfurizing agent is added from the feed pipe 13, and the desulfurizing agent is limestone powder. The coal is added from the coal inlet pipe 11, and the desulfurizing agent enters the furnace 1 under the drive of the secondary air in the secondary air pipe 12. The outlet of the furnace 1 and the inlet of the cyclone separator 3 are sprayed with a denitration ag...

Embodiment 2

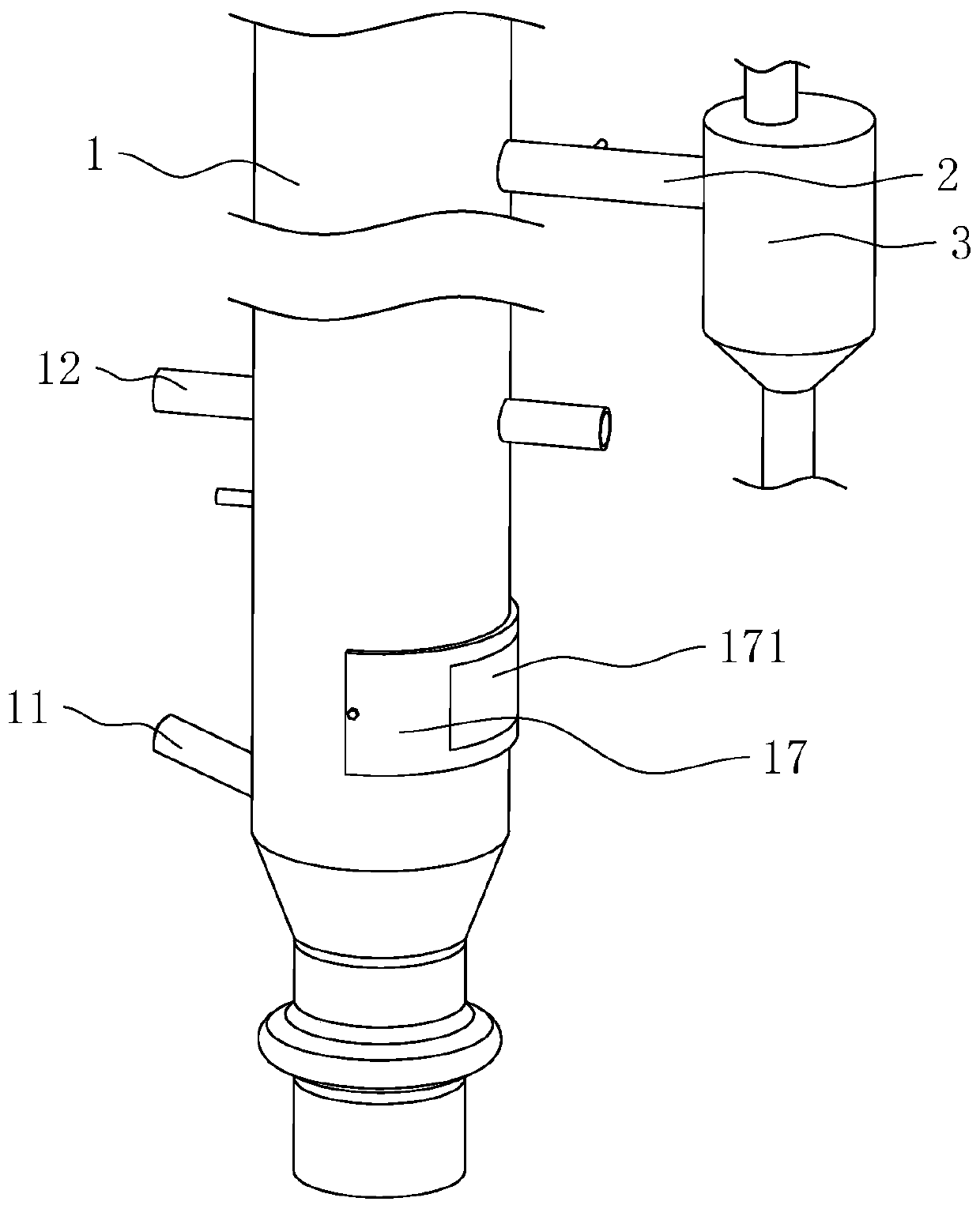

[0042] A method for efficient desulfurization and denitrification of coal combustion, referring to figure 2 The difference from Embodiment 1 is that the furnace 1 is provided with a coal inlet pipe 11, a secondary air pipe 12 and a discharge port sequentially from bottom to top along the height direction, and the discharge port of the furnace 1 is connected to the cyclone separator 3 through the pipeline 2. A desulfurizing agent is sprayed into the furnace 1 near and above the secondary air duct 12, and the desulfurizing agent is limestone powder.

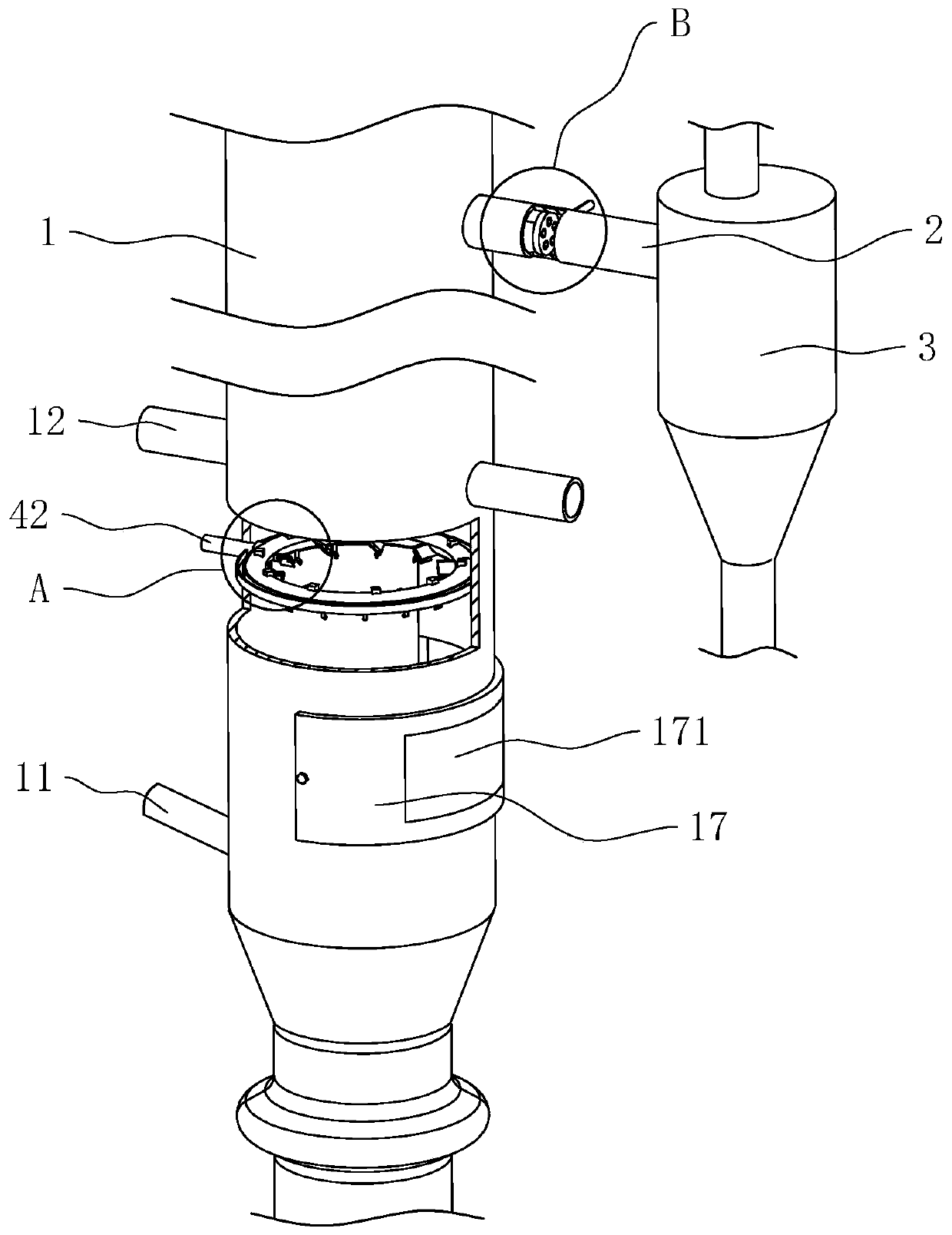

[0043] refer to image 3 and Figure 4 , the inner wall of the furnace 1 and between the coal inlet pipe 11 and the secondary air pipe 12 are fixedly provided with a mounting frame 15, and the mounting frame 15 is equipped with a support ring 4 through bolts, combined with Figure 4 The side of the support ring 4 facing downward is provided with a first notch 41 along its circumferential direction, the support ring 4 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com