Multi-stage driving circuit

A driving circuit and driving signal technology, which is applied in the direction of instruments and static indicators, etc., can solve the problem of excessive occupied area, achieve the effect of reducing the area of the circuit board and saving the occupation of the panel frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

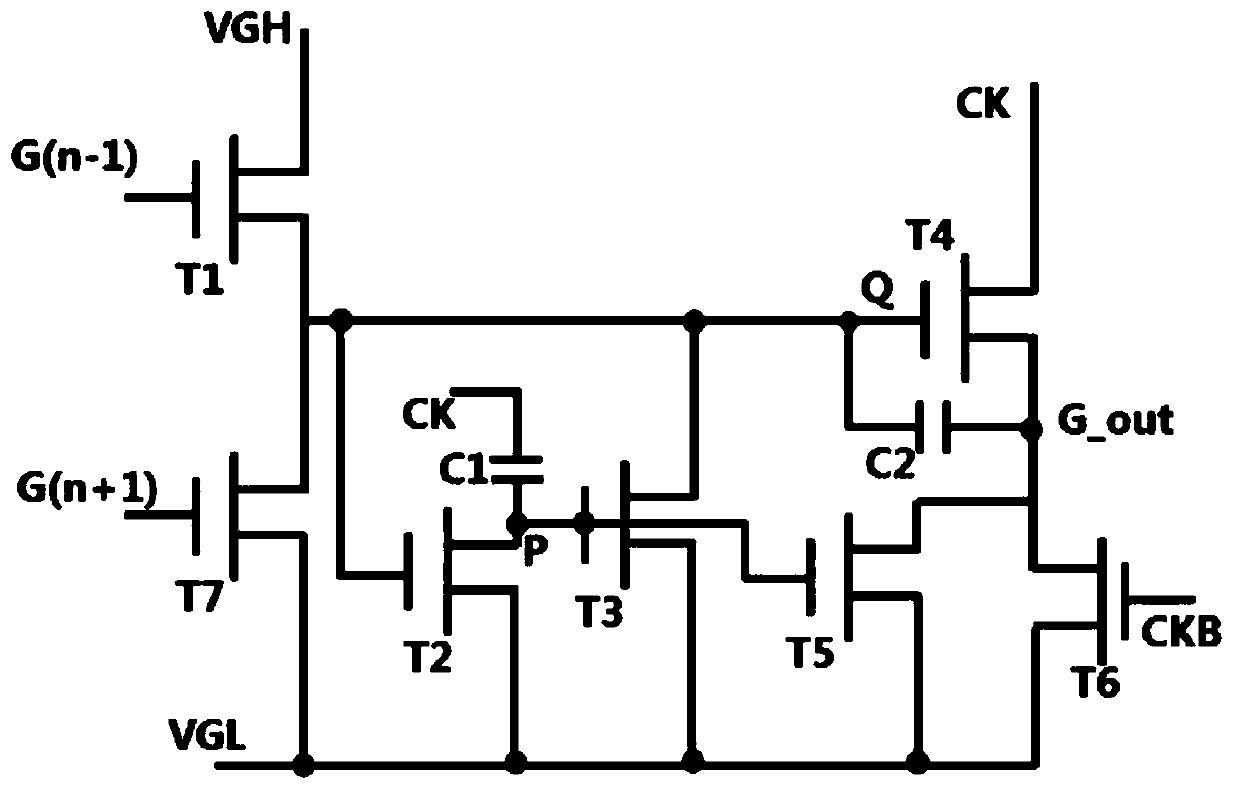

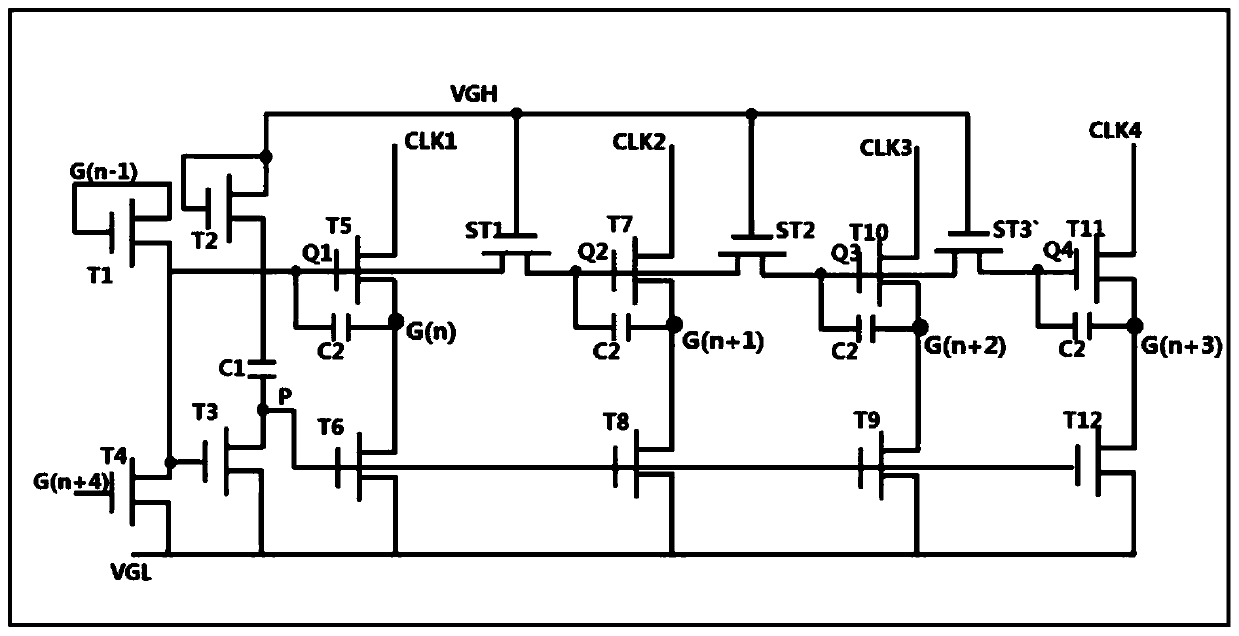

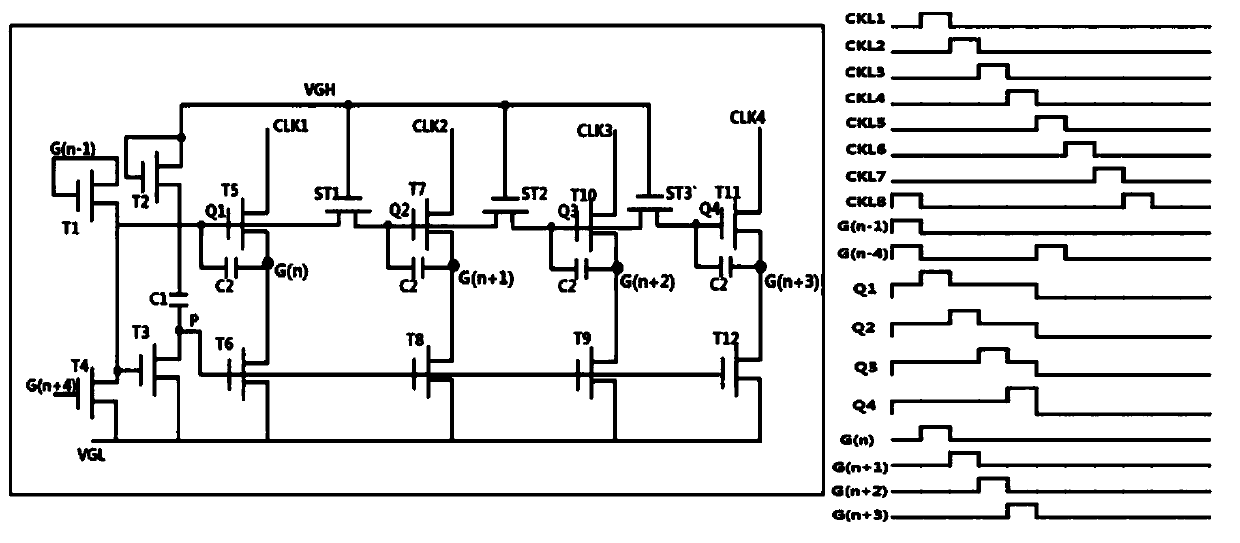

[0023] In some specific embodiments, the GIP circuit is generally designed to be distributed on both sides of the display area (Active Area), such as figure 1 A 7T2C-GIP drive circuit is shown, which is a single-stage output (G_out in the figure). In addition, the 4 clock signals of the GIP circuit unit correspond to 4 output signals. If this GIP circuit wants to output G(n), G(n+1), G(n+2), G(n+3) 4-level output signal, you need 28 TFTs and 8 capacitors, we are figure 2 In the shown embodiment, a new type of circuit is proposed. Under the same function of generating 4-level gate signals, the number of TFTs is 15, which is 13 fewer than the number of TFTs in the existing GIP circuit. The reduction in the number of TFTs can obviousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com