Cold-hot compress product and preparation method thereof

A technology for cold and hot compresses and products, which is applied in the directions of gel preparation, cooling appliances for therapeutic treatment, heating appliances for therapeutic treatment, etc. , Excellent heat and cold storage performance, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

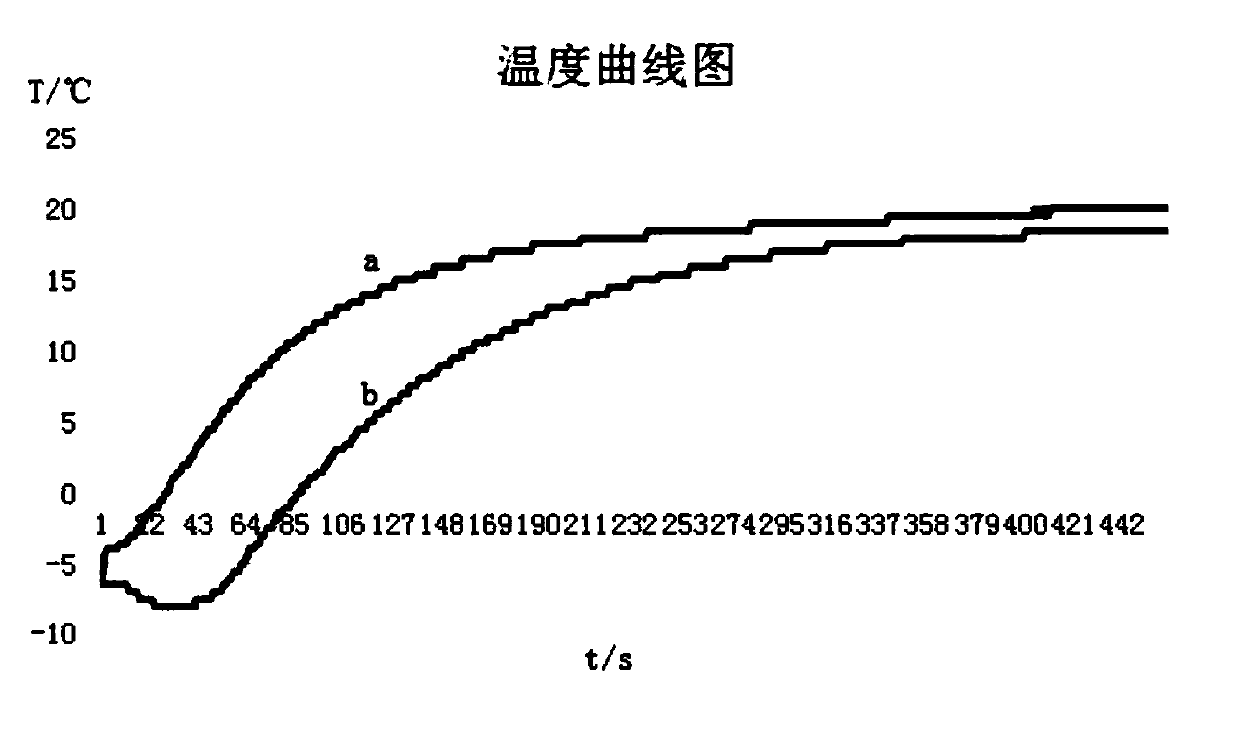

Image

Examples

Embodiment 1

[0028] A preparation method of a hot and cold compress product comprises the following steps:

[0029] Step 1. Weigh the following raw materials: 90 kg of acrylamide, 18 kg of methylol acrylamide, 150 kg of glycerin, 2 kg of sodium chloride, and 240 kg of purified water;

[0030] Step 2, first add purified water and glycerin to the reaction kettle, then add acrylamide, methylolacrylamide and sodium chloride, and then stir together for 24 hours to obtain the spare materials;

[0031] Step 3, filling the spare material obtained in step 2 in an outer bag, pressing an aluminum plate on the outer bag containing the spare material for 120 minutes to form an elastic gel in the outer bag;

[0032] Step 4, remove the outer bag, wrap the elastic gel with a wrapping cloth, and wrap the wrapping cloth along the shape of the elastic gel to obtain a hot and cold compress product.

[0033] Step 5: Carry out quality inspection on the hot and cold compress products obtained in Step 4, and pac...

Embodiment 2

[0037] A preparation method of a hot and cold compress product comprises the following steps:

[0038] Step 1. Weigh the following raw materials: 50 grams of acrylamide, 100 grams of methylolacrylamide, 340 grams of glycerin, 10 grams of sodium chloride, and 500 grams of purified water;

[0039] Step 2, first add purified water and glycerin to the reaction kettle, then add acrylamide, methylolacrylamide and sodium chloride, and then stir together for 12 hours to obtain spare materials;

[0040] Step 3, filling the standby material obtained in step 2 in an outer bag, pressing an aluminum plate on the outer bag containing the standby material for 30 minutes to form an elastic gel in the outer bag;

[0041] Step 4, remove the outer bag, wrap the elastic gel with a wrapping cloth, and wrap the wrapping cloth along the shape of the elastic gel to obtain a hot and cold compress product.

[0042] Step 5: Carry out quality inspection on the hot and cold compress products obtained in ...

Embodiment 3

[0046] A preparation method of a hot and cold compress product comprises the following steps:

[0047] Step 1. Weigh the following raw materials: 210 grams of acrylamide, 12 grams of methylolacrylamide, 270 grams of glycerin, 8 grams of sodium chloride, and 500 grams of purified water;

[0048] Step 2, first add purified water and glycerin to the reaction kettle, then add acrylamide, methylolacrylamide and sodium chloride, and then stir together for 12 hours to obtain spare materials;

[0049] Step 3, filling the standby material obtained in step 2 in an outer bag, pressing an aluminum plate on the outer bag containing the standby material for 60 minutes to form an elastic gel in the outer bag;

[0050] Step 4, remove the outer bag, wrap the elastic gel with a wrapping cloth, and wrap the wrapping cloth along the shape of the elastic gel to obtain a hot and cold compress product.

[0051] Step 5: Carry out quality inspection on the hot and cold compress products obtained in S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com