Forming device for sub-circular sealing head

A technology for forming equipment and heads, which is applied in the field of forming equipment for subcircular heads, can solve problems such as low production efficiency, high cost, and difficult quality, and achieve reduced procurement costs or production costs, high consistency, and production fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific structure of the present invention will be further described below:

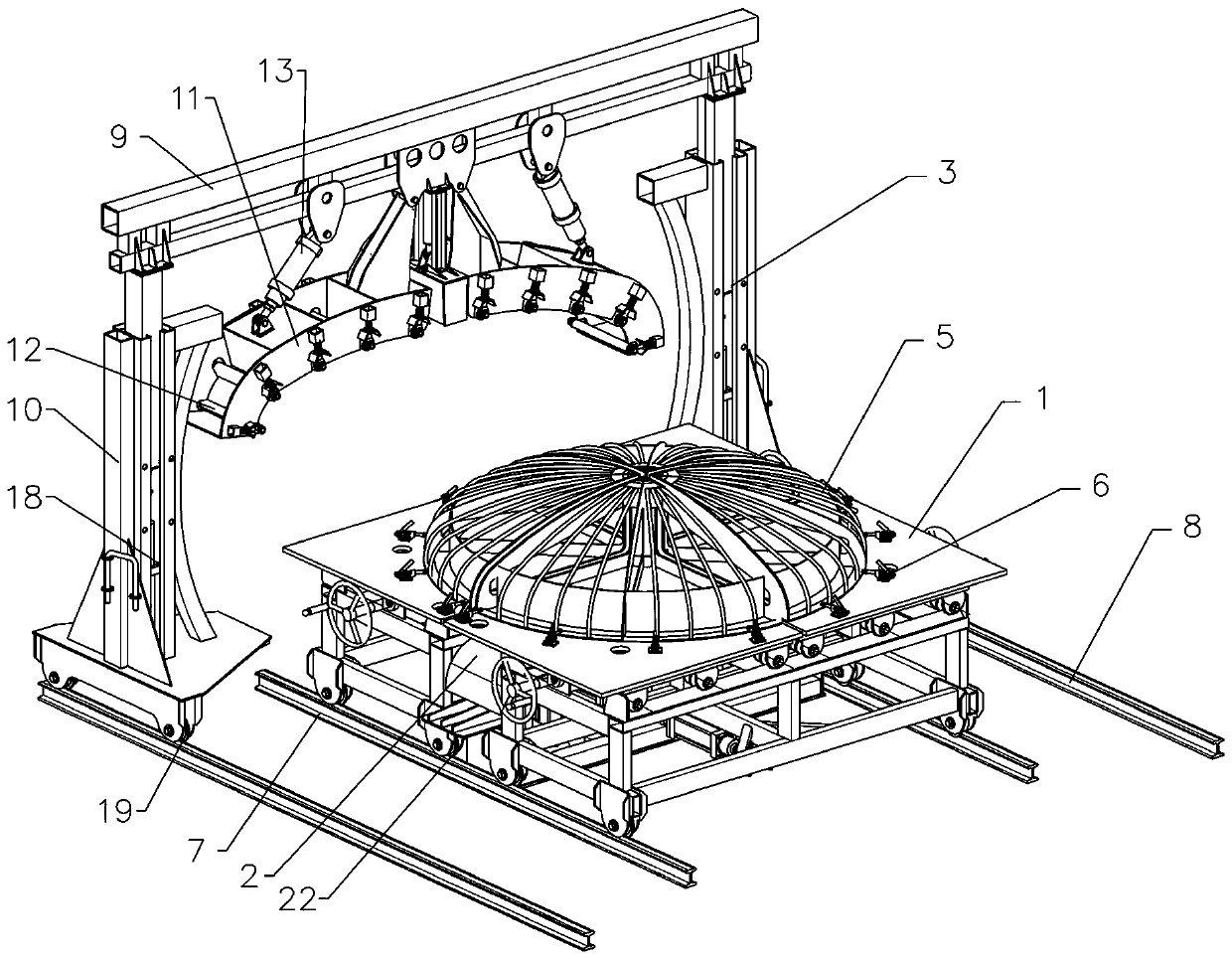

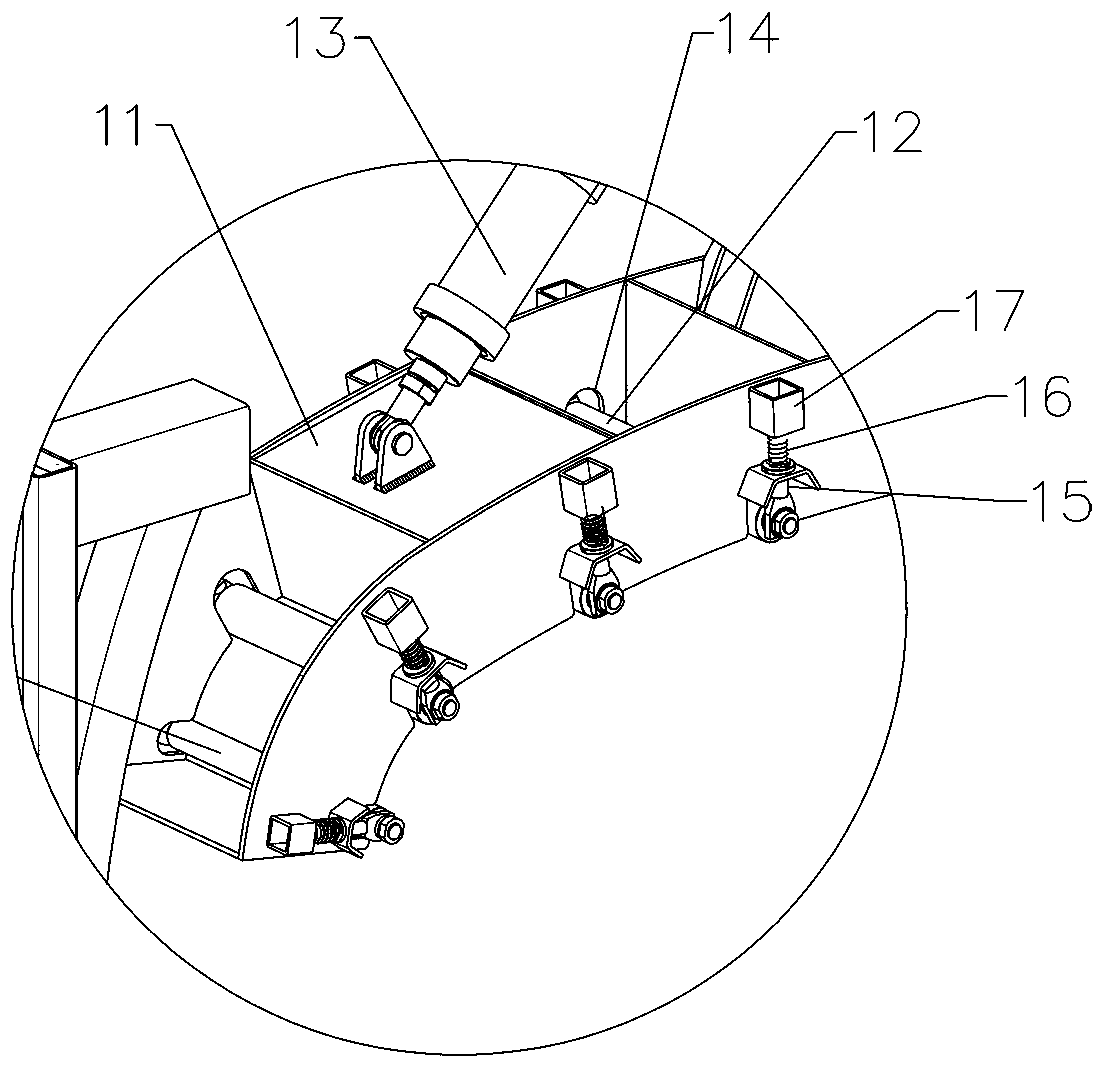

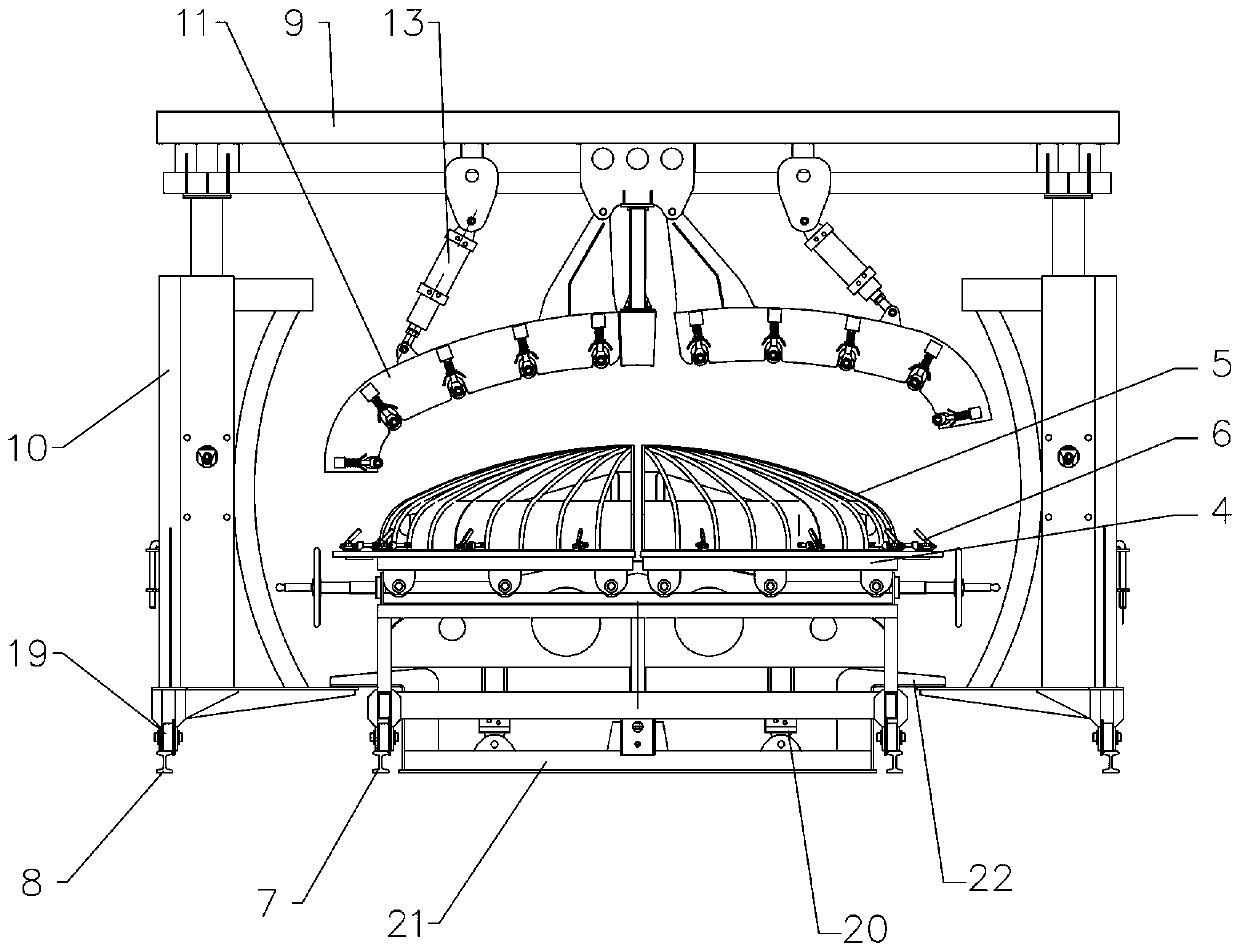

[0032] The present invention is a forming equipment for sub-circular heads, with a three-dimensional structure such as figure 1 with 7 As shown, figure 1 It is the picture when the flared mould is not raised, Figure 7 It is a perspective view of the flaring section when the mould is raised.

[0033] The device includes a standard head split mold platform 1 and a flaring compact mold gantry movable frame 3.

[0034] Specifically, the standard head split mold platform 1 includes a half-body moving platform 4, two semi-circular molds 5 are respectively arranged on the two half-body moving platforms 4, and the two semi-circular molds 5 are assembled into a complete circular head mold. Between the two halves of the mobile platform 4 is set up a flaring section mold 2 that can be raised and lowered. The flaring section mold 2 has an arc shape on the upper side, and the flaring section mold 2 is raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com