Bismaleimide resin-based composite material, radome and preparation method of bismaleimide resin-based composite material

A technology of bismaleimide resin and maleimide resin, which is applied in the field of bismaleimide resin-based composite materials, radome and its preparation, can solve the problems of high manufacturing cost of autoclave, temperature, Difficult to control pressure, high energy consumption in autoclave molding, etc., to achieve the effects of reduced equipment cost and energy consumption, simple mold design, and reduced wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

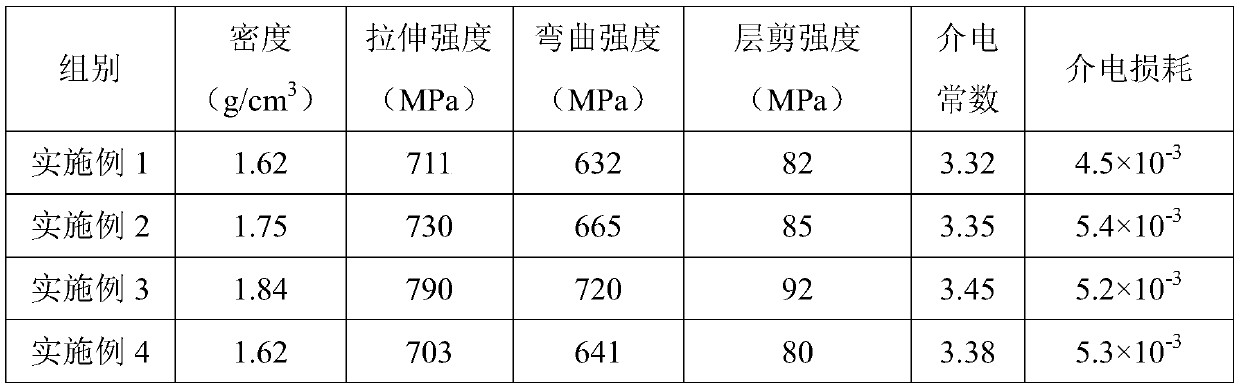

Embodiment 1

[0034] The bismaleimide resin prepreg adopted in the present embodiment takes D-type quartz fiber cloth as reinforcing material, and the thickness of quartz fiber cloth is 0.14mm, and surface density is 165g / m 2 , the mass content of bismaleimide resin in the prepreg is 60%, the thickness of the prepreg is 0.3mm, and the surface density of the prepreg is 412g / m 2 .

[0035] The method for preparing bismaleimide resin-based composite material and radome described in the present embodiment may further comprise the steps:

[0036] S1. Lay 21 layers of bismaleimide resin prepreg in the mold, wrap and seal it with a vacuum bag film, and then vacuumize the inside of the mold to a vacuum degree of less than 0.08MPa. The bismaleimide resin prepreg is pre-compacted at high temperature, and pre-compacted after the 1st, 5th, 9th, 13th, 17th, and 21st layers are laid, and each pre-compaction is 10 minutes;

[0037] S2. Keep the inside of the mold evacuated until the vacuum degree is les...

Embodiment 2

[0041] The bismaleimide resin prepreg adopted in the present embodiment takes B-type quartz fiber cloth as reinforcing material, and the thickness of quartz fiber cloth is 0.2mm, and surface density is 220g / m 2 , the mass content of bismaleimide resin in the prepreg is 50%, the thickness of the prepreg is 0.35mm, and the surface density of the prepreg is 440g / m 2 .

[0042] The method for preparing bismaleimide resin-based composite material and radome described in the present embodiment may further comprise the steps:

[0043] S1. Lay 21 layers of bismaleimide resin prepreg in the mold, wrap and seal it with a vacuum bag film, and then vacuumize the inside of the mold until the vacuum degree is less than 0.09MPa. The bismaleimide resin prepreg is pre-compacted at high temperature, and pre-compacted after the 1st, 5th, 9th, 13th, 17th, and 21st layers are laid, and each pre-compaction is 20 minutes;

[0044] S2. Keep the inside of the mold evacuated until the vacuum degree i...

Embodiment 3

[0048] The bismaleimide resin prepreg adopted in the present embodiment takes B-type quartz fiber cloth as reinforcing material, and the thickness of quartz fiber cloth is 0.28mm, and surface density is 288g / m 2 , the mass content of bismaleimide resin in the prepreg is 40%, the thickness of the prepreg is 0.4mm, and the surface density of the prepreg is 480g / m 2 .

[0049] The method for preparing bismaleimide resin-based composite material and radome described in the present embodiment may further comprise the steps:

[0050] S1. Lay 21 layers of bismaleimide resin prepreg in the mold, wrap and seal it with a vacuum bag film, and then vacuumize the inside of the mold to a vacuum degree of less than 0.09MPa. The bismaleimide resin prepreg is pre-compacted at high temperature, and pre-compacted after laying the 1st, 5th, 9th, 13th, 17th, and 21st layers respectively, each pre-compaction is 30 minutes;

[0051] S2. Keep the inside of the mold evacuated until the vacuum degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com