Ice pattern UV primer for ice silk pattern effect, and button with ice silk pattern effect and manufacturing process thereof

A manufacturing process and button technology, applied in the field of buttons, can solve the problems of no high-end feeling, single color of the coating layer, and high cost, and achieve the effect of meeting the needs of the color system, enriching the metal color, and increasing the bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

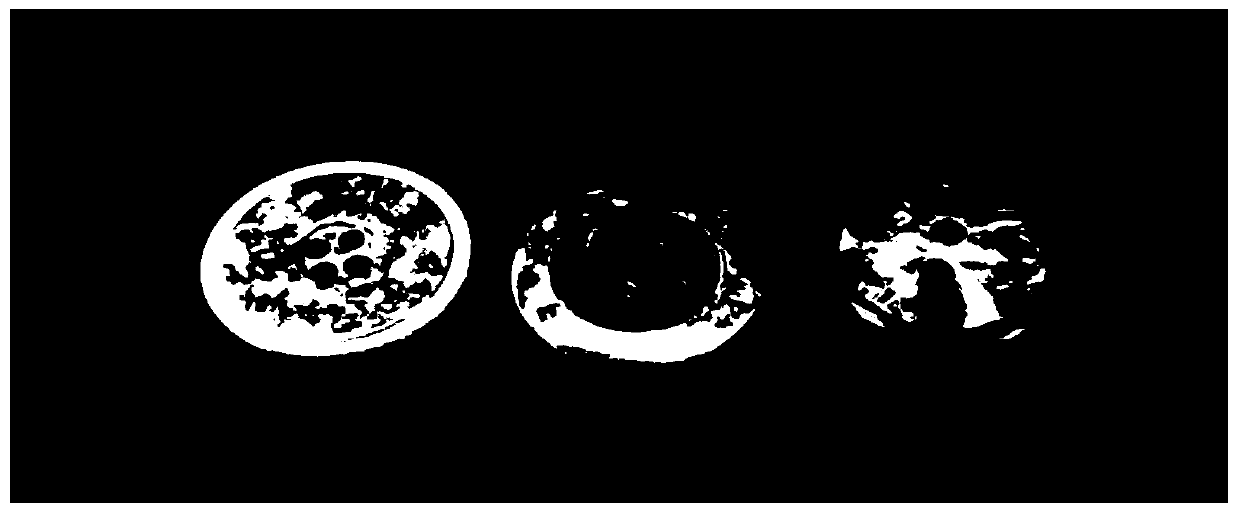

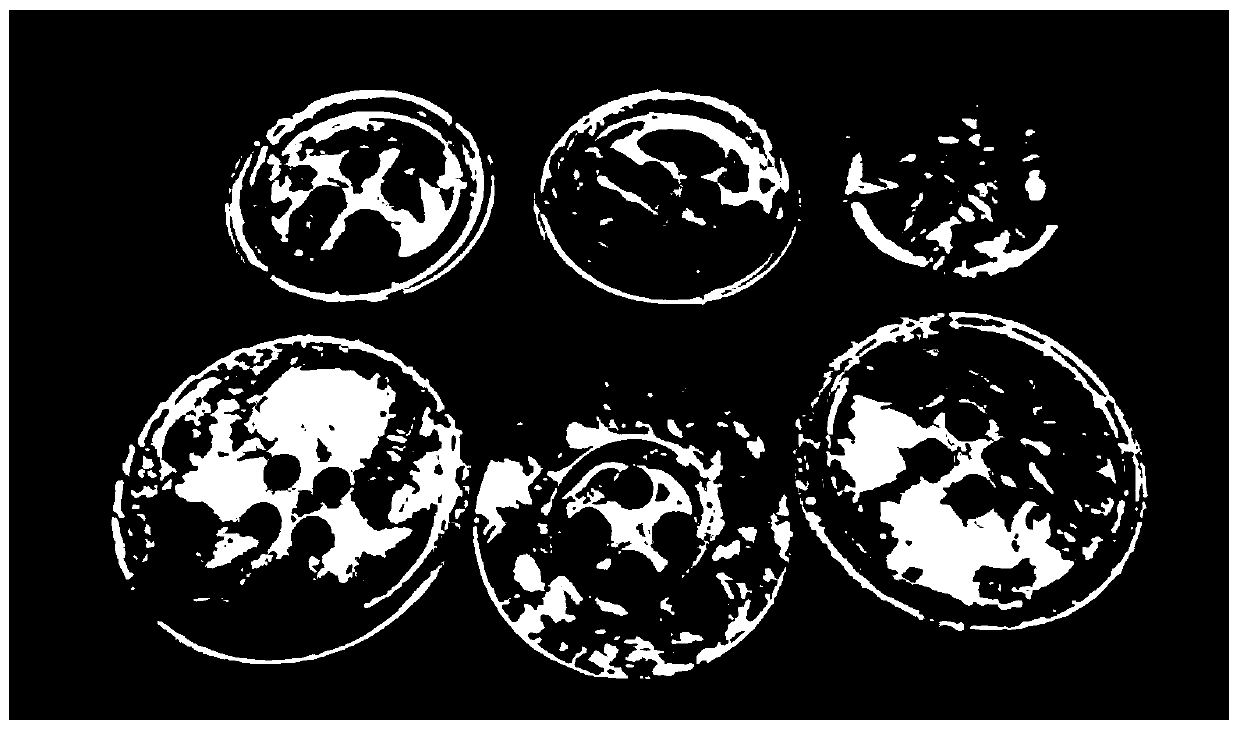

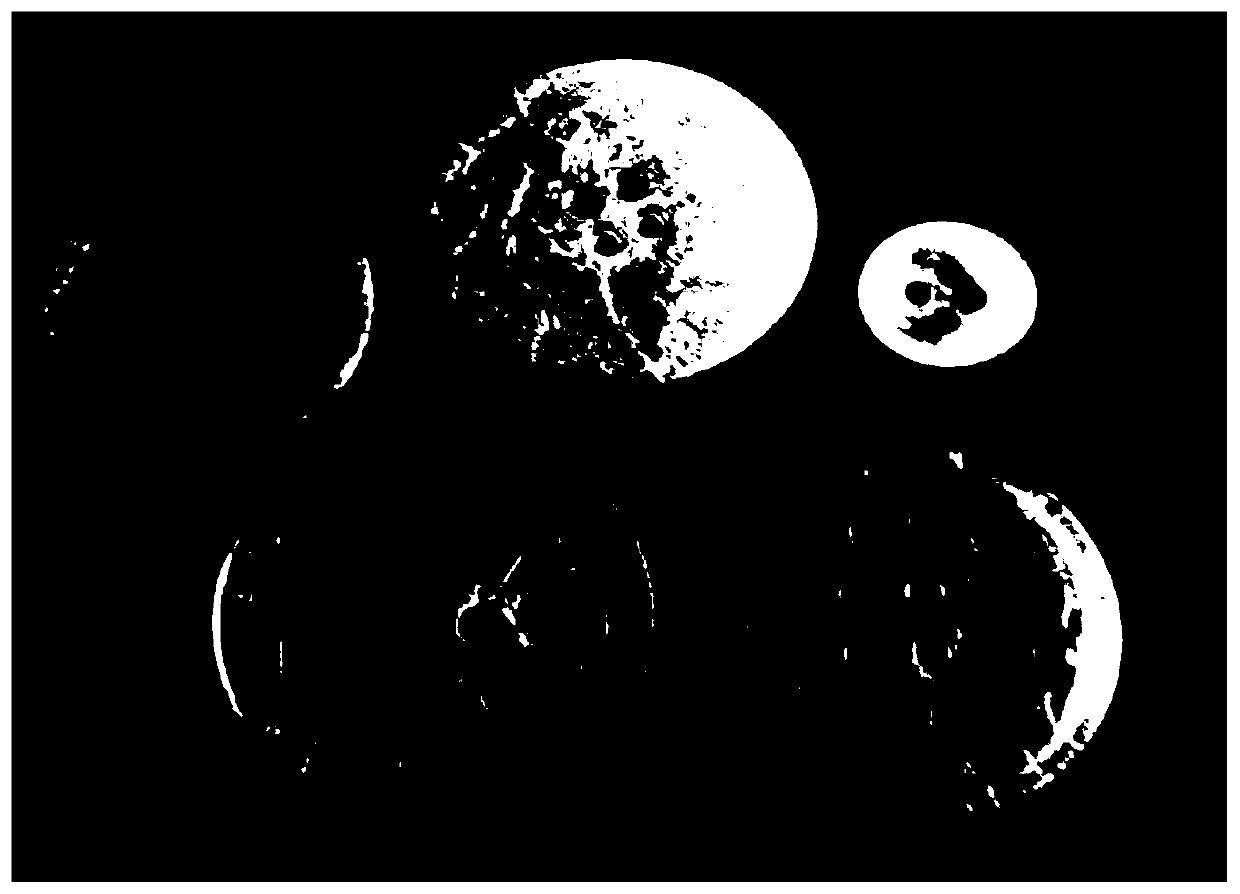

Image

Examples

preparation example Construction

[0069] The present invention provides a kind of preparation method of the ice pattern UV primer that is used for the ice pattern effect button described in the above technical scheme, comprising:

[0070] Mix UV ice flower resin, trimethylolpropane triacrylate, tripropylene glycol diacrylate, and photosensitizer evenly, then add solvent, defoamer, and leveling agent, and mix evenly.

[0071] It is preferable to mix ice flower resin, trimethylolpropane triacrylate, tripropylene glycol diacrylate, and photosensitizer evenly, then add solvent, defoamer, and leveling agent, mix evenly, and then filter. When spraying, use a filter to filter it into a special sealed paint bucket and wait for use.

[0072] The above-mentioned proportions and compositions of the present invention have been clearly described, and will not be repeated here. The present invention does not limit the filtering, as long as those skilled in the art are familiar with it.

[0073] The invention provides a pro...

Embodiment 1

[0097] Formula composition of ice texture UV primer (grams)

[0098] Ice resin: (acrylic polymer) 56.6

[0099] Cross-linking monomer: trimethylolpropane triacrylate: 18.5

[0100] Tripropylene glycol diacrylate: 10.5

[0101] Photosensitizer: 3.8

[0102] Ethyl ester or toluene: 10

[0103] Defoamer: 0.1

[0104] Leveling agent: 0.5

[0105] After testing the effect of the first primer material, the surface of the semi-finished product is sprayed first, the air pressure is 2.0-3.5 kg, the button travel speed is 2.8-3.5CM per second, the ice silk texture primer is processed, and the energy of the UV ultraviolet light is controlled. After (600~900) mj / cm2 is effectively cured, the semi-finished product is placed vertically outward in the evaporative coating machine for aluminum and nickel plating. When coating, turn on the vacuum mode and set the vacuum to 3.0-2. And set the pre-melting time 6.0-7.0 seconds, pre-melting maintenance 5.0-6.0 seconds, pre-melting voltage 3.6...

Embodiment 2

[0111] Formula composition of ice texture UV primer (grams)

[0112] Ice flower resin: (acrylic polymer) 56.8

[0113] Cross-linking monomer: trimethylolpropane triacrylate: 18.8

[0114] Tripropylene glycol diacrylate: 10.8

[0115] Photosensitizers: 4

[0116] Ethyl ester or toluene: 10.5

[0117] Defoamer: 0.11

[0118] Leveling agent: 0.46

[0119]After testing the effect of the primer material of the second implementation, the surface of the semi-finished product is first sprayed, the air pressure is 2.0-3.5 kg, the button travel speed is 2.8-3.5CM per second, the ice silk texture primer is treated, and the UV ultraviolet light is effective. After solidification, put the semi-finished product vertically outward into the evaporative coating machine for aluminum and nickel plating. When coating, turn on the vacuum mode to set the vacuum to 3.0-2, and set the pre-melting time to 6.0-7.0 seconds. The melting time is 5.0-6.0 seconds, the pre-melting voltage is 3.60-3.80 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com