Oil-based inkjet ink set and printing method

A technology of oil-based ink and ink set, applied in ink, printing, copying/marking methods, etc., can solve problems such as deformation of transparent folders, and achieve the effect of preventing print-through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

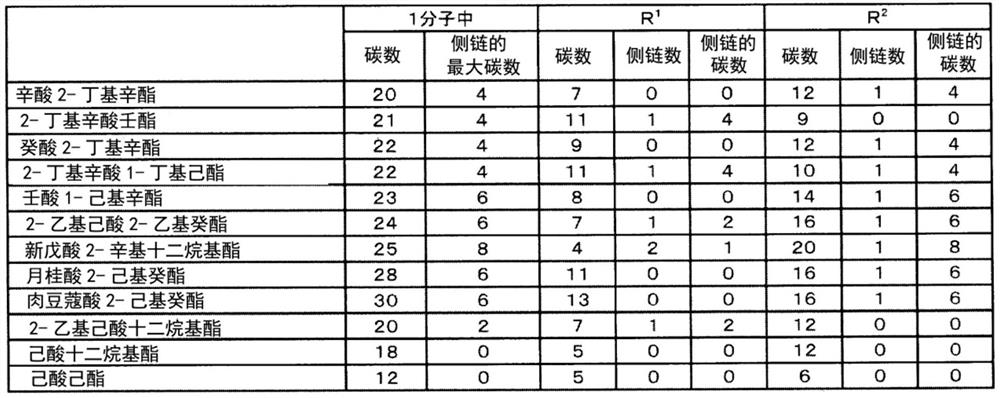

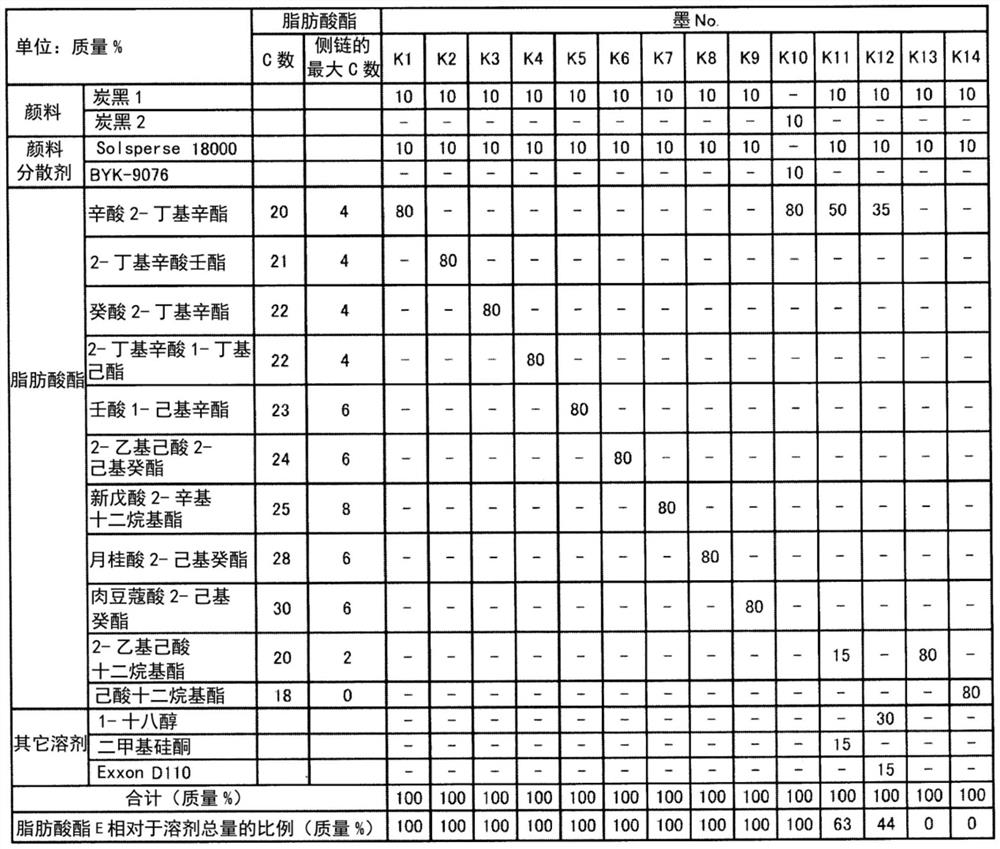

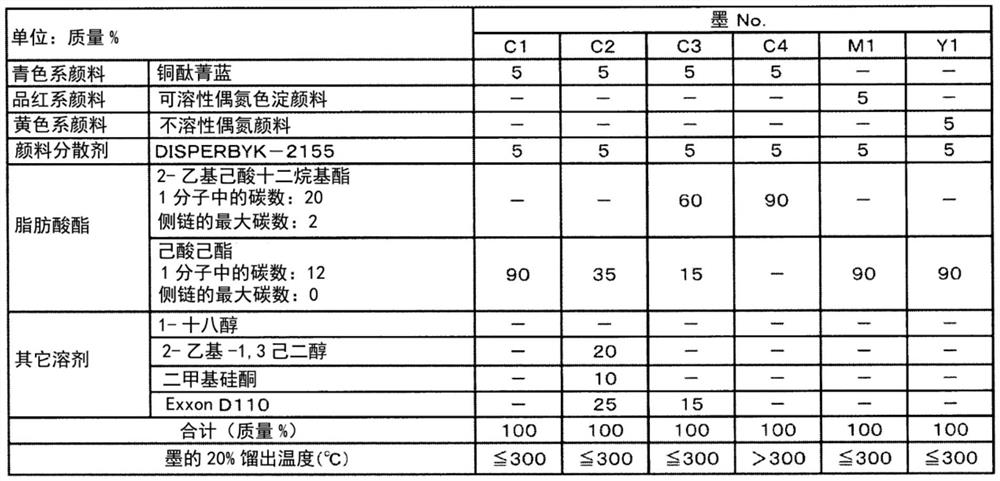

Method used

Image

Examples

Embodiment 1

[0226] In Examples 11, 12, in the first ink, the same fatty acid esters, and other solvents as in Example 1 were used, and good results were obtained. Further, in the first ink, the amount of fatty acid ester having a side chain having a carbon number of 4 or more and a fatty acid ester having a carbon number of 20 or more has a higher amount of a surface concentration.

[0227] In Examples 13, 14, the second ink is changed to the first embodiment, and the solvent formulation is changed.

[0228] In Examples 15, 16, the male ink, yellow ink was used in the second ink, and good results were obtained. As in Example 1, it is known that cyan inks are used in the second ink from the viewpoint of the surface concentration of the synthetic black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com