Polymer-containing sludge emulsion profile control system and preparation method thereof

A technology of poly-oil sludge and system, which is applied in the field of poly-oil-containing emulsified profile control system and its preparation, can solve the problems of oilfield oil sludge pollution in an effective and economical way, achieve the effect of improving the ability of emulsification profile control and meeting the requirements of profile control technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also relates to the preparation method of the described polymer-containing oil sludge emulsification profile control system, which comprises the following steps:

[0039] (1) mixing the poly-containing oil sludge with water, optionally sieving the mixture;

[0040] (2) The emulsifier is uniformly mixed with the optionally sieved poly-oil sludge-water mixture at a concentration of 0.05-1.0%;

[0041] (3) Add T-type polyacrylamide as a suspension stabilizer and stir to obtain an emulsified suspension system;

[0042] (4) Then slowly add intensifiers A, B, C and D in sequence, and stir to obtain the emulsified profile control system containing poly-oil sludge.

Embodiment 1

[0054] Mix the poly-oil-containing sludge and sewage at a ratio of 1:5, and sieve the mixture. The particle size of the solid particles in the sieved poly-oil-containing sludge-water mixture is about 20 μm; add T-type polyacrylamide (weight average molecular weight 800 μm) to the beaker 10,000) as a suspension stabilizer, and make its concentration 2000mg / L. Afterwards, the emulsifier (which is a mixture of sodium dodecylbenzenesulfonate and dodecyldimethylsulfopropyl betaine (2:1)) is uniformly mixed with the water mixture containing poly oil sludge at a concentration of 0.1%, and added Stir in the beaker for 20min to prepare a stable emulsified suspension system; then slowly add enhancer A chromium lactate (concentration is 600mg / L), B ammonium nitrate (concentration is 600mg / L), C sodium thiosulfate (concentration is 400mg / L) L) and D oxalic acid (concentration: 400 mg / L), stirred for 15 minutes to obtain the emulsified profile control system containing poly-oil sludge.

...

Embodiment 2

[0057] Mix the poly-oil-containing sludge and sewage at a ratio of 1:7, and sieve the mixture. The particle size of the solid particles in the sieved poly-oil-containing sludge-water mixture is about 20 μm; add T-type polyacrylamide (weight average molecular weight 800 μm) to the beaker Ten thousand) as a suspension stabilizer, and make its concentration 3000mg / L. Afterwards, mix the emulsifier (sodium dodecylbenzenesulfonate) with a concentration of 0.2% and the water mixture containing poly-oil sludge evenly, add it to the beaker and stir for 20 minutes to prepare a stable emulsified suspension system; then slowly add the enhancer A in sequence Chromium lactate (1000mg / L), B ammonium nitrate (800mg / L), C urea (600mg / L) and D oxalic acid (1000mg / L), stirred for 30min to obtain the emulsified profile control system containing poly-oil sludge.

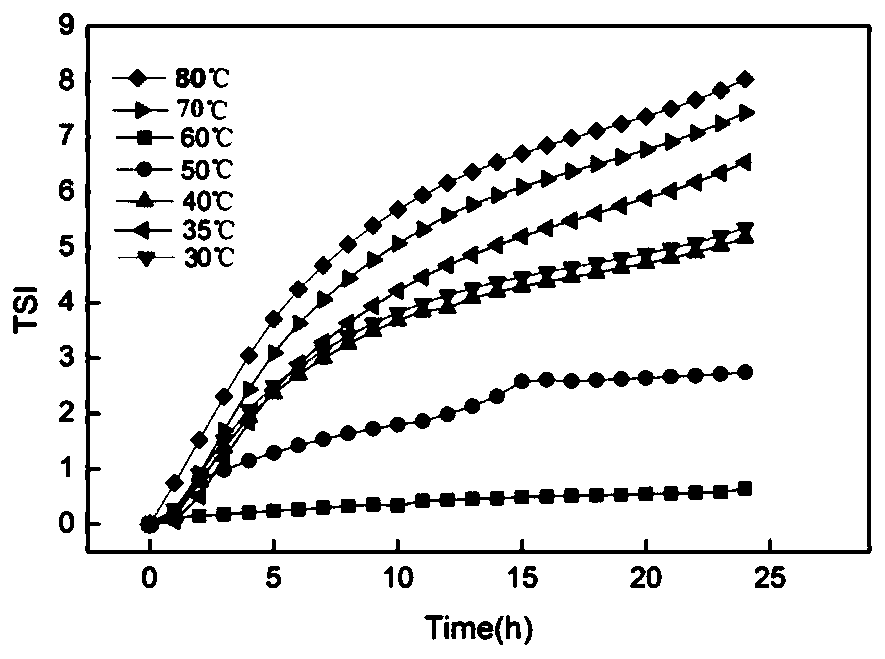

[0058] The gelling time of the obtained emulsified profile control system is 42 hours, the gelling strength is D, the breakthrough pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com