A high-temperature and high-pressure steam secondary fracturing device and method for coal seam drilling

A high-temperature and high-pressure, secondary fracturing technology, used in safety devices, earth-moving drilling, gas discharge, etc., can solve the limitation of application scope and actual effect, the water vapor pressure cannot reach the magnitude of fracturing, and cannot produce High temperature and high pressure mixed steam and other problems, to avoid long-term ineffective fracturing, avoid blind fracturing, and prevent scalding operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

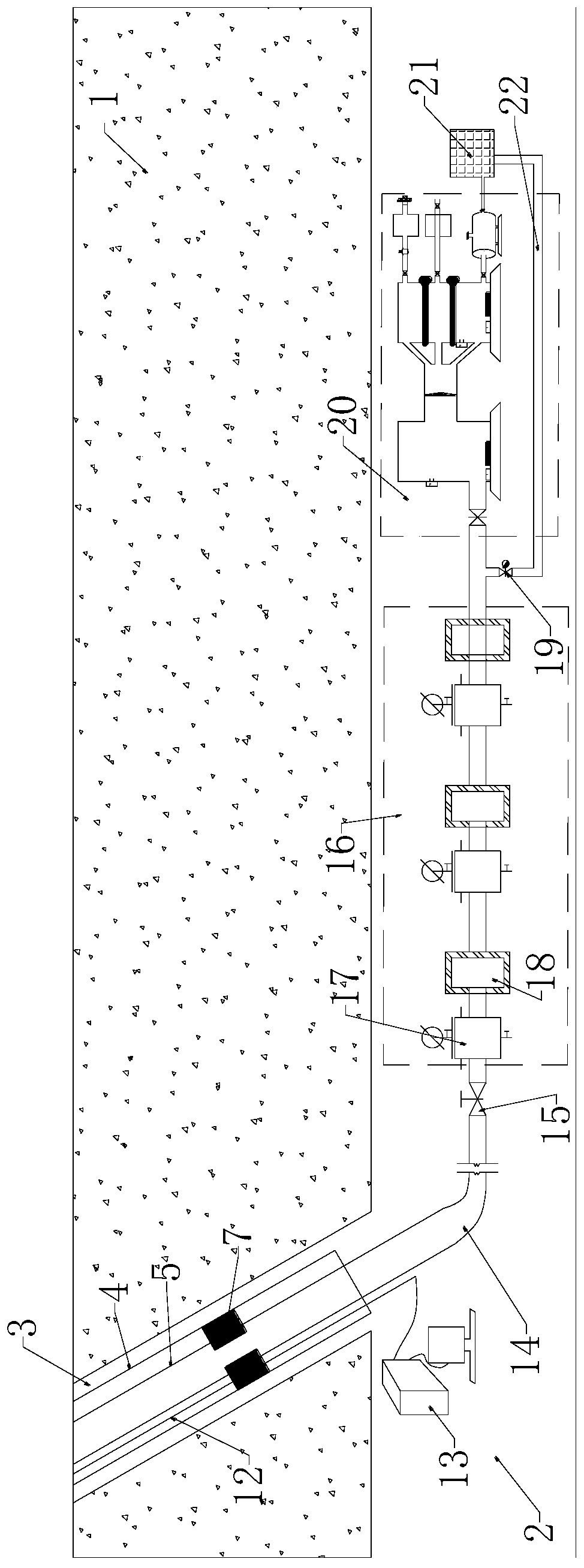

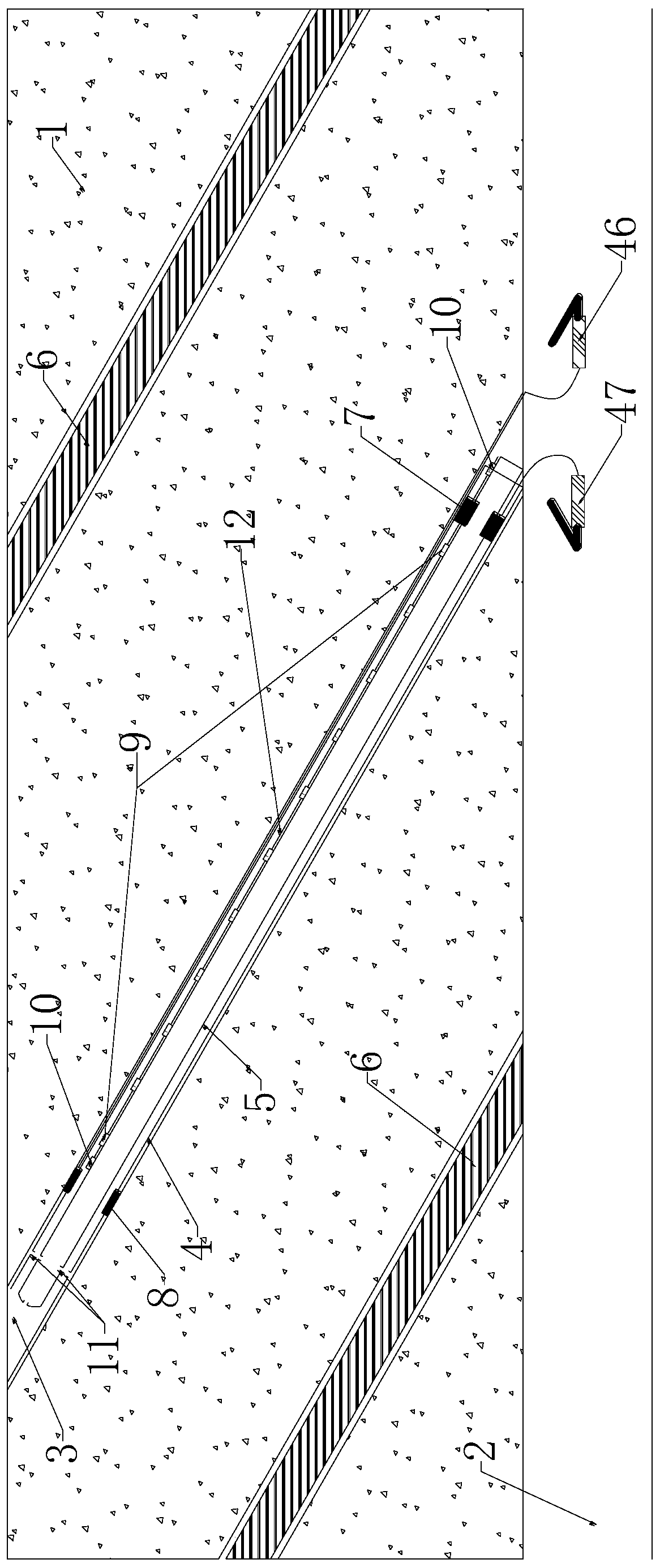

[0045] like Figure 1~4 As shown, a high-temperature, high-pressure steam secondary fracturing device for coal seam drilling proposed by the present invention includes a high-temperature, high-pressure steam proportioning device 20, a three-stage temperature raising and boosting system 16, and pipelines and monitoring components for secondary fracturing;

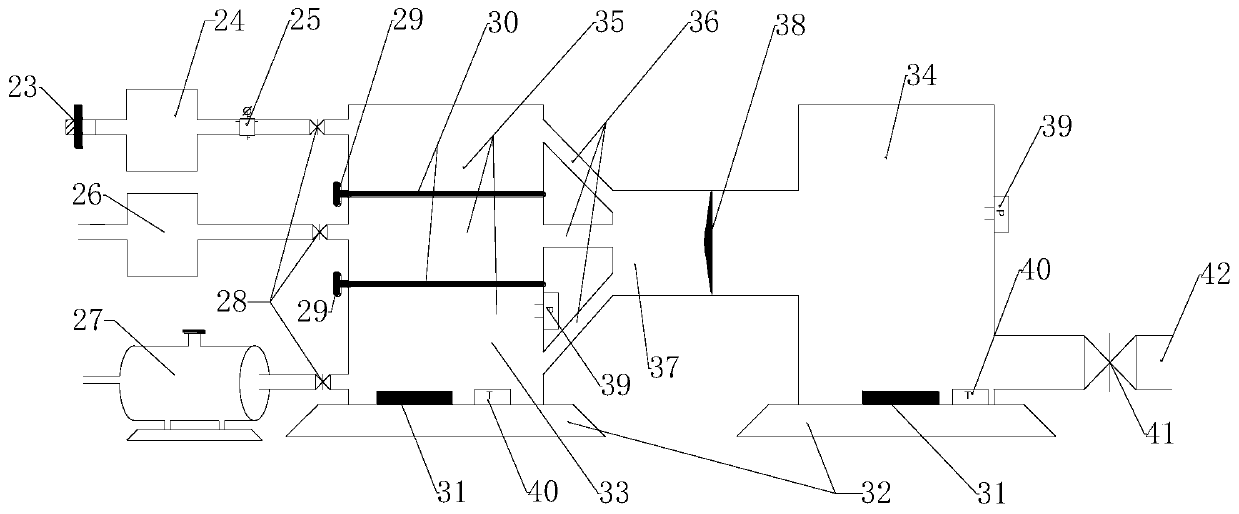

[0046] The high-temperature and high-pressure steam proportioning device 20 includes an air storage tank 24 for storing air, which can be supplied with compressed air by a compressor 23; a protective gas storage tank 26 for storing protective gas, A high-temperature and high-pressure steam boiler 27 for converting water into high-temperature pressurized steam, A tank 33 for heat preservation and proportioning of air, protective gas, and high-temperature pressurized steam, and a tank A 33 for receiving and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com