Display panel suitable for under-screen camera

A display panel and camera technology, which is applied in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve problems such as poor color purity, conflict between color purity and transmittance requirements, and influence of AMOLED screen transmittance. , to achieve superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

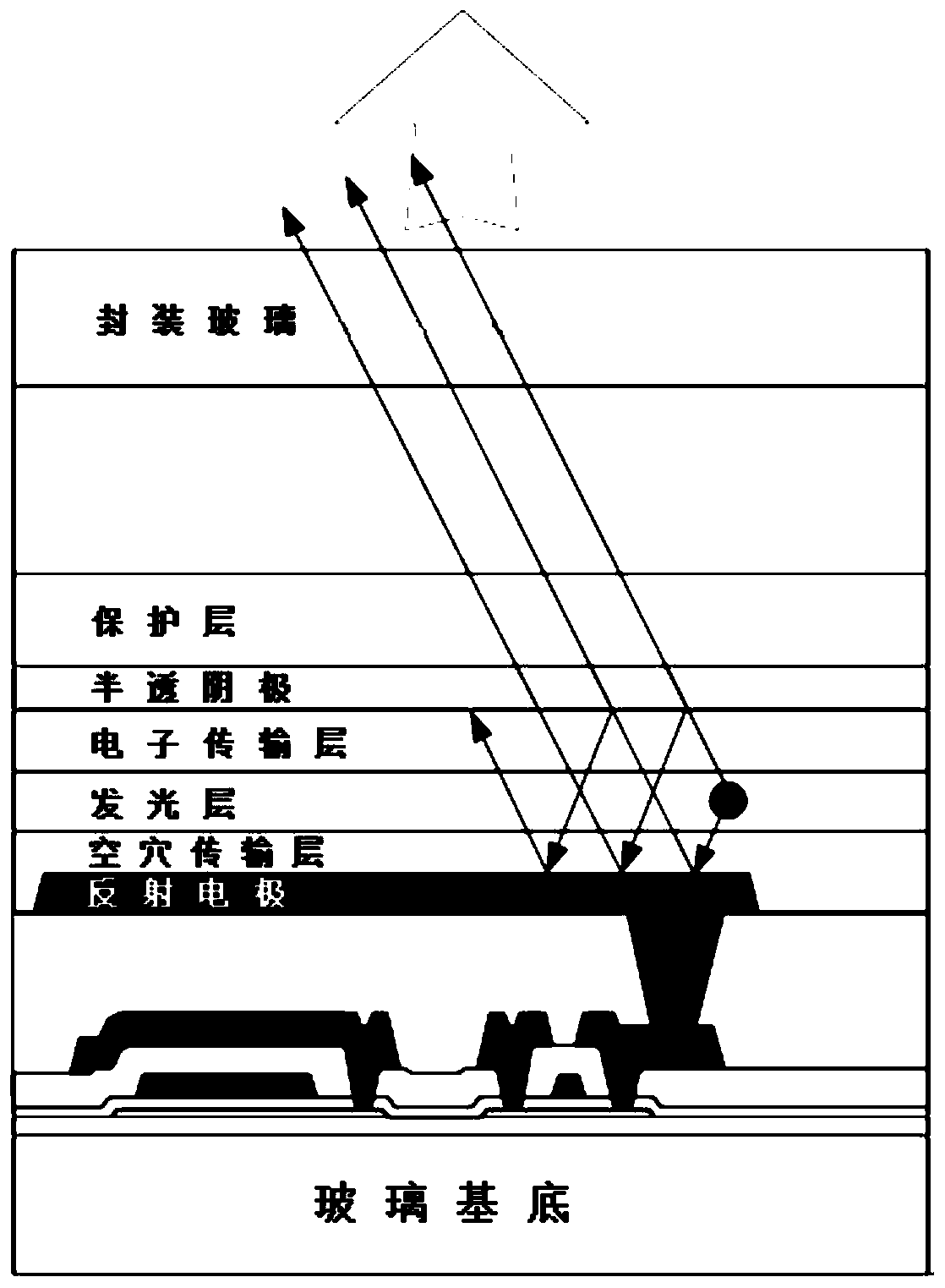

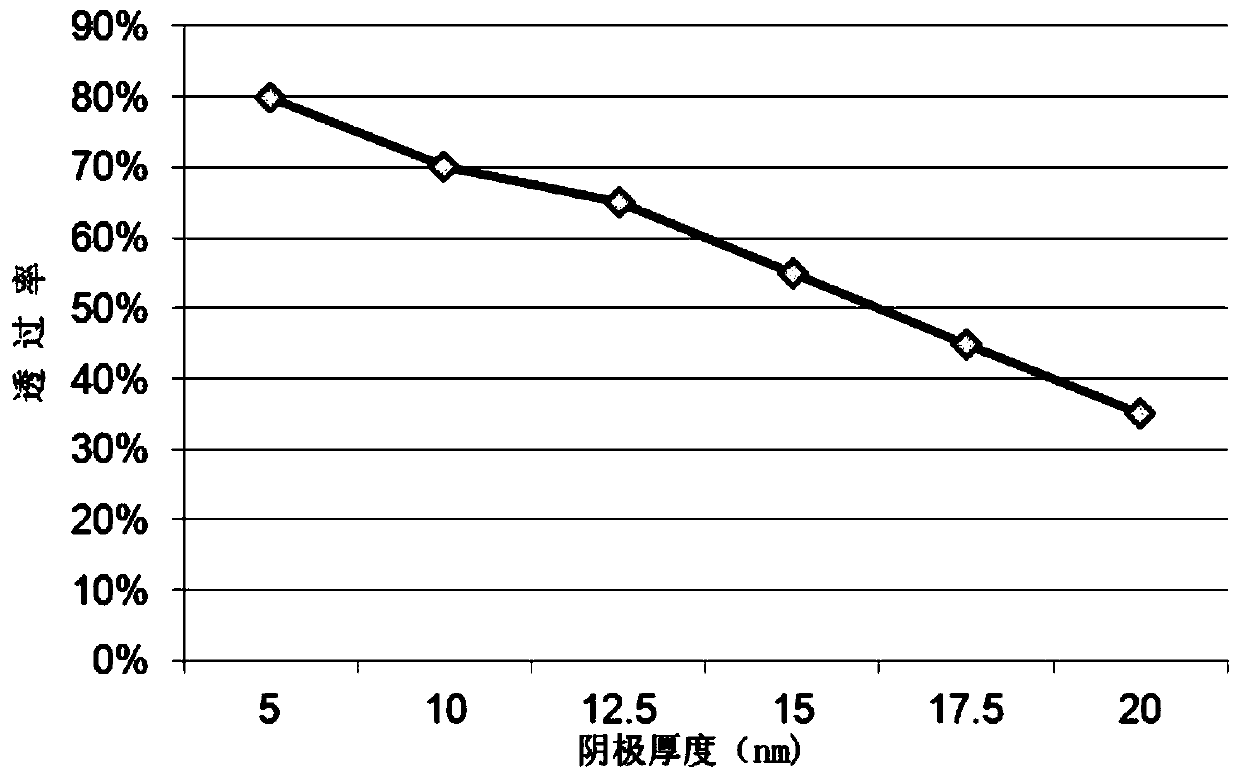

[0047] Such as Figure 9As shown, only the anode E and the display driving backplane F are the same in the display area a and the display area b (the same process), and the hole transport layer, light-emitting layer, electron transport layer, and cathode above the anode are separated, respectively, according to the same light and color performance The requirements match the corresponding functional film layer, in which the cathode A1 is an ultra-thin structure (the transmittance is greater than 70%), and the cathode A2 is a semi-permeable structure (the transmittance is between 35% and 55%).

[0048] The characteristics of this solution: the display backplane and driving scheme of area a and b are consistent with the traditional ones, and the display panels with the same light and color performance are matched by using their respective diode structure differences.

Embodiment 2

[0050] Such as Figure 10 As shown, the electron transport layer B, the hole transport layer D, the anode E and the display drive backplane F in the display a area are the same as the display b area (the same process), and the light-emitting layer and the cathode are separated from each other. Due to the quantum dot device in the a area The OLED device in area b shows a slight difference in voltage driving, and uses the difference compensation balance of driving signals in area a and area b. This signal includes power signal VDD, VEE, and data signal Vdata, etc.; the cathode A1 is an ultra-thin structure ( The transmittance is greater than 70%), and the cathode A2 is a semi-permeable structure (the transmittance is between 35% and 55%).

[0051] Features of this scheme: the power-driven backplane, anode, and functional film layer of area a and area b are the same, only the light-emitting layer and cathode are different, and the process is relatively simple; the driving scheme ...

Embodiment 3

[0053] Such as Figure 11 As shown, the electron transport layer B, the hole transport layer D, the anode E and the display drive backplane F in the display a area are the same as the display b area (the same process), and the light-emitting layer and the cathode are separated from each other. Due to the quantum dot device in the a area The OLED device in area b shows a slight difference in voltage driving. Using the pre-experimental selection of light-emitting layer materials in area a and b, the materials for quantum dot light-emitting layer C1 and OLED organic light-emitting layer C2 with similar light and color properties are obtained. For organic functional layer B , D can also be selected through device pre-experimentation; the cathode A1 is an ultra-thin structure (the transmittance is greater than 70%), and the cathode A2 is a semi-permeable structure (the transmittance is between 35% and 55%).

[0054] Features of this solution: the power-driven backplane, anode, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com