Optimal voltage boundary overmodulation method for permanent magnet synchronous motor without electrolytic capacitor drive

A permanent magnet synchronous motor and electrolytic capacitor technology, which is used in motor generator control, electromechanical brake control, AC motor control, etc., can solve problems such as back-off and output voltage vector phase jump, avoid jumping, and ensure voltage utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

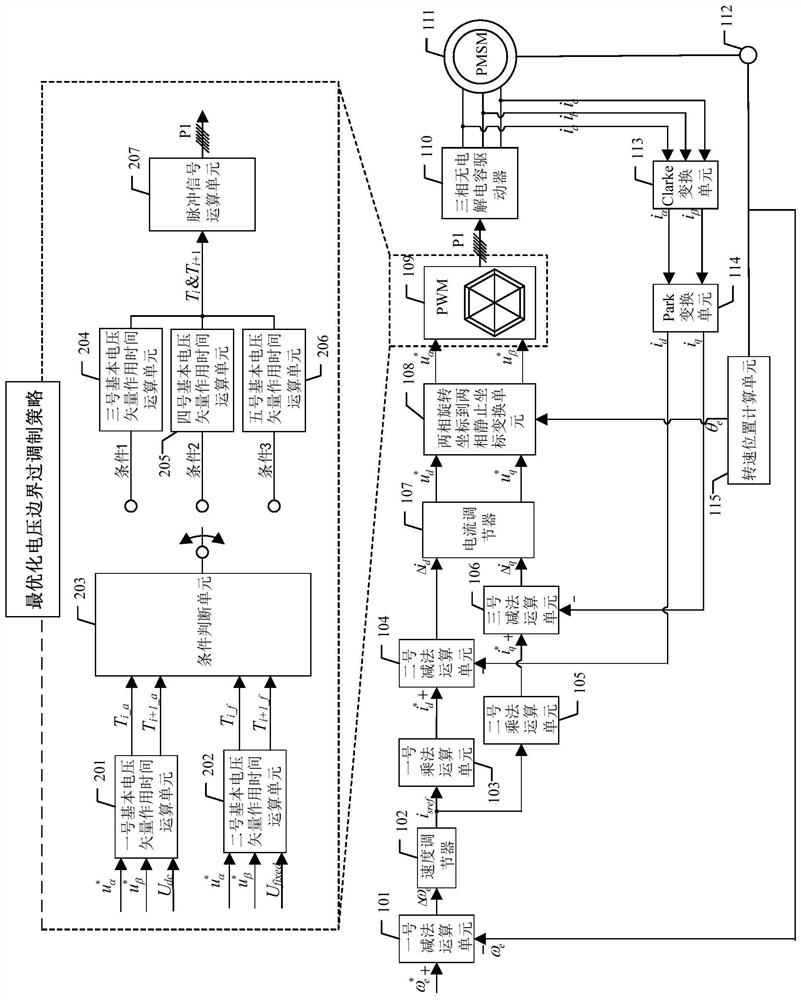

[0033] Specific implementation mode 1. Combination figure 1 As shown, the present invention provides a permanent magnet synchronous motor non-electrolytic capacitor driver voltage boundary optimization overmodulation method, comprising the following steps:

[0034] Step 1: Collect and process the actual three-phase current of the three-phase non-electrolytic capacitor driver to obtain the α-axis voltage command u α * and β-axis voltage command u β * ;

[0035] Step 2: Use the No. 1 basic voltage vector action time operation unit 201 to command the α-axis voltage u α * , β-axis voltage command u β * and the actual voltage U output by the three-phase electrolytic capacitor driver dc Perform calculations to obtain the first expected action time T of two adjacent basic voltage vectors in the permanent magnet synchronous motor vector control i_a , T i+1_a ; Simultaneously, the No. 2 basic voltage vector action time operation unit 202 is used to command the α-axis voltage ...

Embodiment

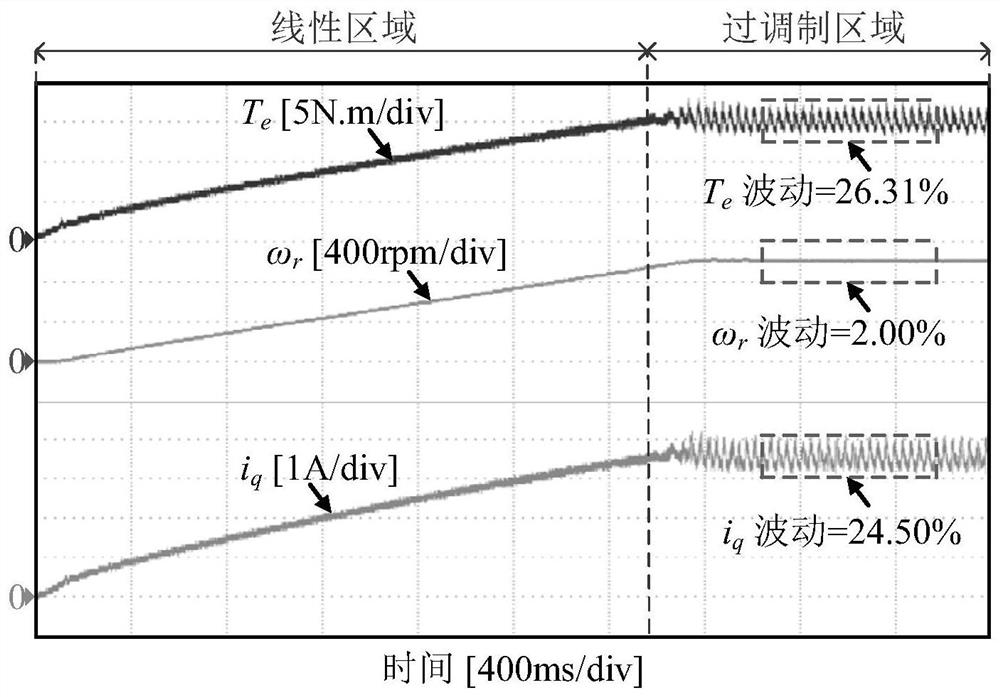

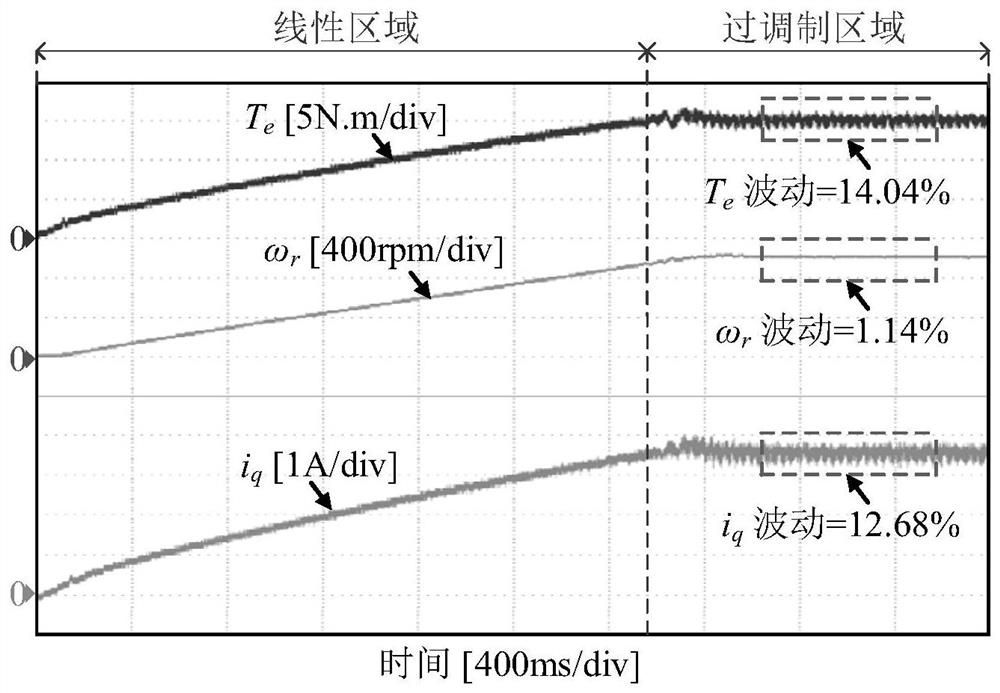

[0056] Embodiment: The effectiveness of the optimal voltage boundary overmodulation strategy proposed by the present invention is verified on the electrolytic capacitor permanent magnet synchronous motor drive system platform. The parameters of the experimental platform are set as follows: the grid voltage is 380V, the grid frequency is 50Hz, the DC bus capacitor is a film capacitor with a capacitance value of 50μF, the d-axis inductance of the motor is 35mH, the q-axis inductance is 54mH, the rotor flux linkage is 0.86Wb, and the number of rotor pole pairs is 3, the rated power is 2.2kW, the rated speed is 1000r / min, and the stator resistance is 2.75Ω. All control algorithms in the experiment are completed in ARM STM32F103. The switching frequency and the current and voltage sampling value update frequency are both set to 6kHz.

[0057] Depend on figure 2 and image 3 It can be seen from the comparison that the control method of the present invention makes the torque fluc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com